Work order scheduling, simplified.

Learn from today’s reliability leaders.

-

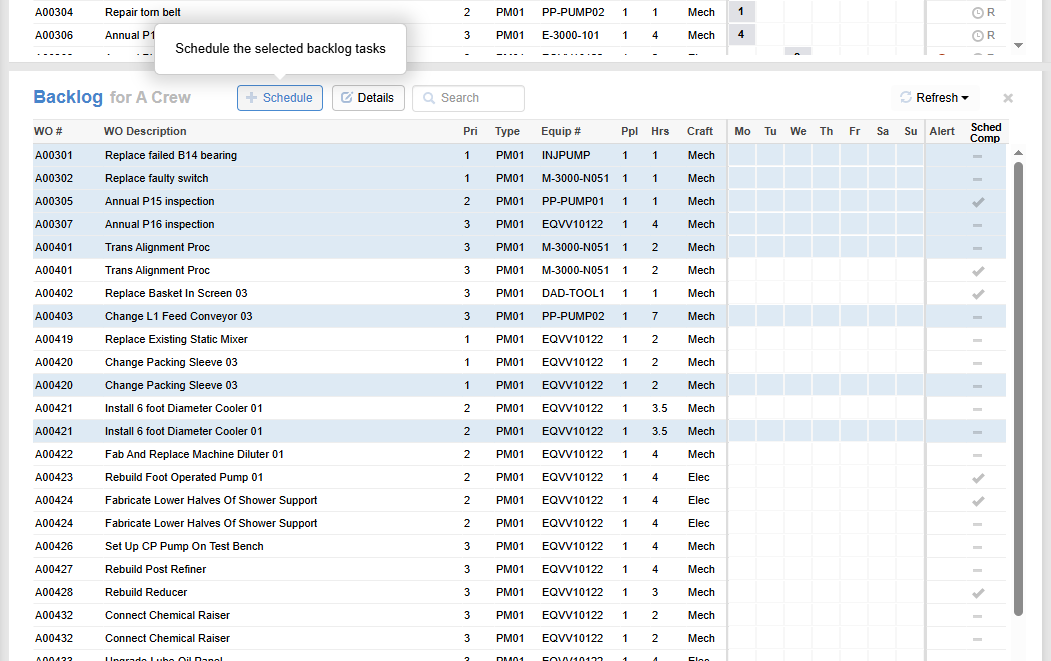

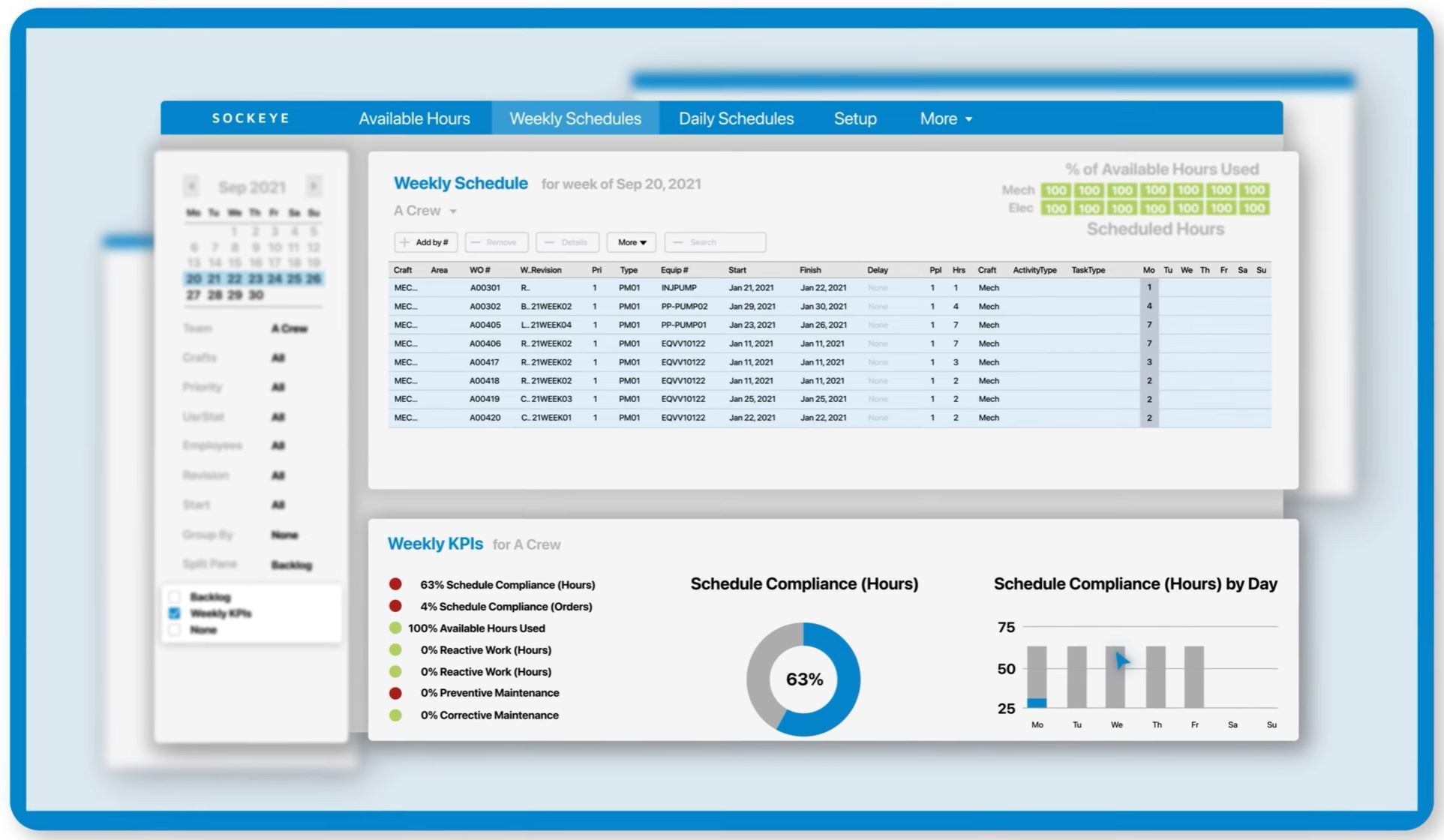

Sockeye: maintenance Scheduling & Reporting Tool

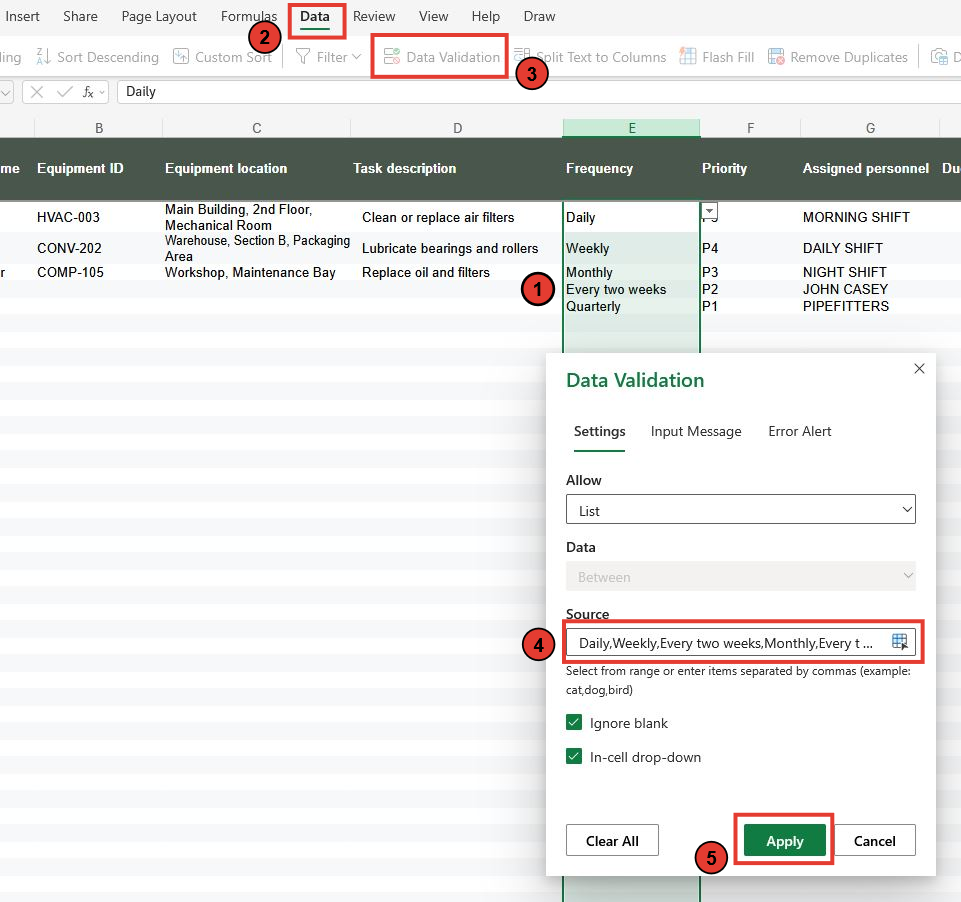

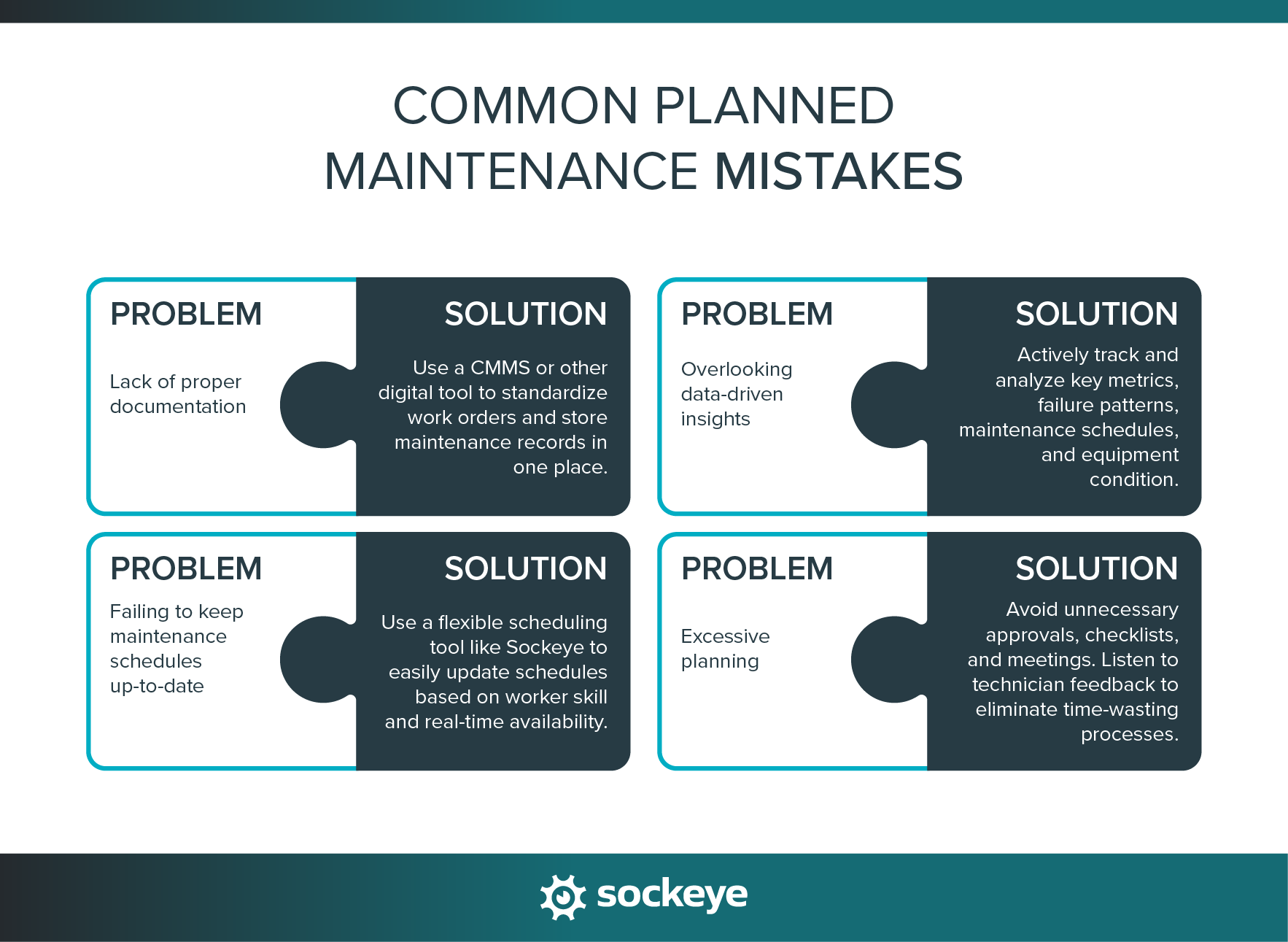

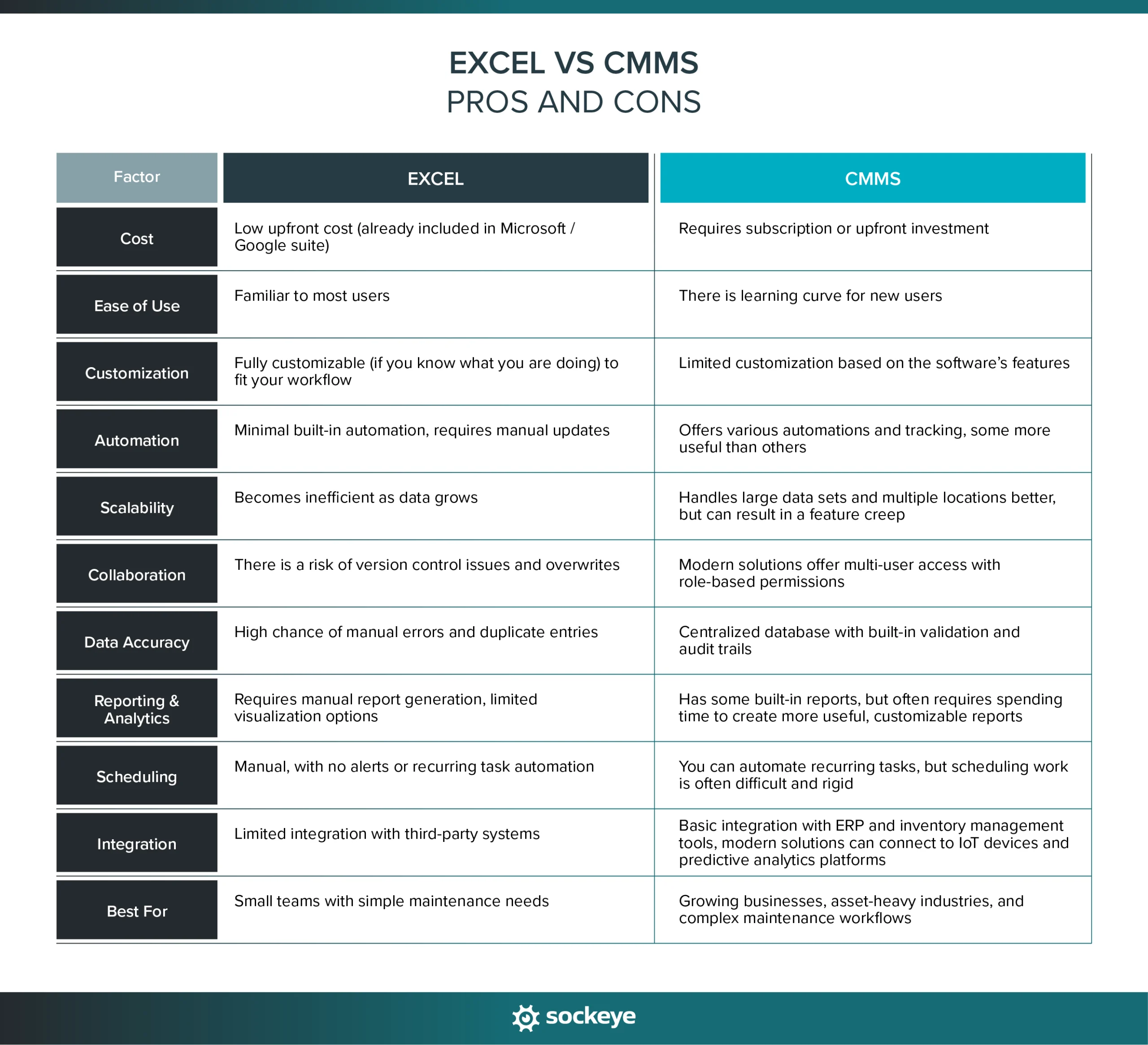

If you are looking to use Excel as your preventive maintenance software, this article will provide you with free scheduling templates — and some guidance on how to use them.

Get Started

Take the next step to a highly productive maintenance team.

Book a Demo