For most maintenance teams, overtime has become part of the job. Labor shortages and constant firefighting make it nearly impossible to get everything done in a standard 40-hour workweek.

But here’s the paradox: cutting overtime often sounds like cutting productivity — when in reality, the opposite can be true.

In many cases, the solution isn’t working harder. It’s working smarter, starting with how you schedule and plan your work.

Why maintenance teams rely so heavily on overtime

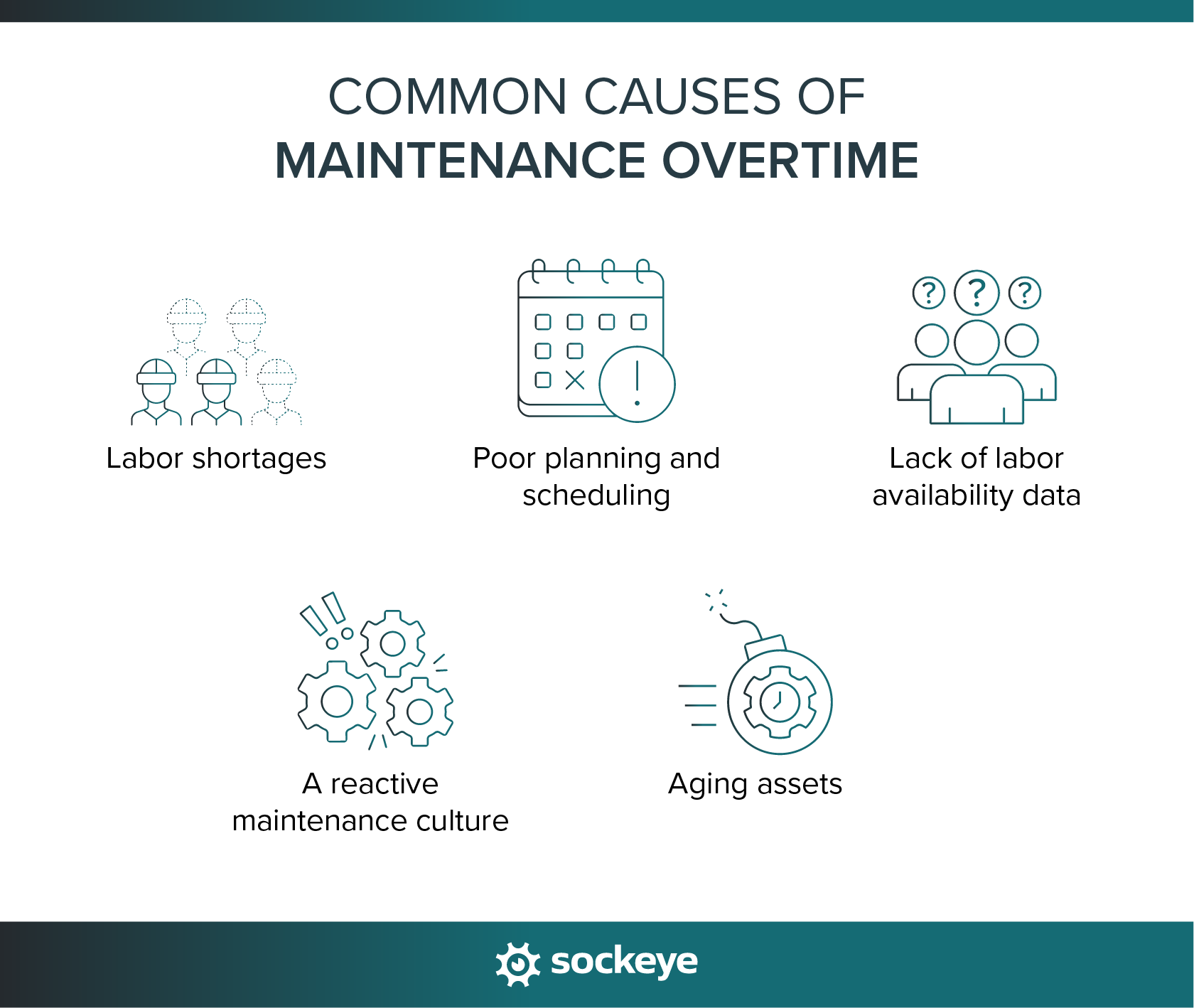

Heavy overtime can rarely be attributed to a single cause. For many plants, it’s the combination of:

- Labor shortages and skill gaps: Over 40% of manufacturers report that there simply aren’t enough qualified people to cover all the work that needs doing. When a technician is out or a key skill is missing, the only option left is for someone else to stay after hours.

- Poor planning and scheduling: Planners spend too much time building schedules and not enough time planning the work itself. Jobs end up starting late, taking longer, or getting pushed into overtime because the prep work wasn’t there.

- Inaccurate labor availability data: It’s hard to plan efficiently when you don’t know exactly who’s available or for how long. Without the ability to easily access and keep the labor availability up to date, it’s easy to overbook or underutilize your crews.

- A reactive maintenance culture: When you’re constantly chasing breakdowns, everything else gets pushed aside. That firefighting mode leads to long days, late nights, and mounting frustration. You reduce overall preventive work, causing more overtime down the line.

Aging assets: The same report we just referenced says 42% of facilities cite aging equipment as the top cause of unplanned downtime. And more unexpected downtime inevitably leads to more maintenance overtime. Not to mention how old equipment requires more upkeep in the first place.

Many of these problems are exacerbated by the lack of adequate work order scheduling software. We often see schedulers schedule unnecessary overtime because the tool they use does not update labor availability as they assign work. It’s a big problem for many traditional maintenance tools.

The scheduling blind spot: Why traditional tools fall short

Even with a solid CMMS or a carefully managed spreadsheet, most schedulers still don’t have a clear, real-time view of who’s actually available to work.

Without that visibility, scheduling turns into a guessing game:

- Work gets overscheduled, leading to burnout, overtime, and rework.

- Some technicians sit underscheduled, which causes frustration and wasted potential.

- Workloads become uneven between shifts and crews, resulting in lower overall productivity.

It’s not that planners aren’t doing their best — it’s that their tools either do not give the correct data, overcomplicate the scheduling process, or force workflows that do not match how scheduling happens on a busy plant floor.

They have to waste time toggling between screens, trying to manually calculate and disperse available labor.

That’s where a tool like Sockeye comes in to save the day — giving maintenance planners and schedulers a real-time picture of capacity as they assign jobs.

How Sockeye cuts overtime and increases productivity

Sockeye is a maintenance scheduling bolt-on that integrates with your existing CMMS or EAM software. It is designed to help teams outsource and simplify the scheduling process, without needing to replace the software they are currently using.

Most importantly for this discussion, Sockeye helps you quickly build balanced, realistic schedules that help you do more work while reducing overtime. Here’s how:

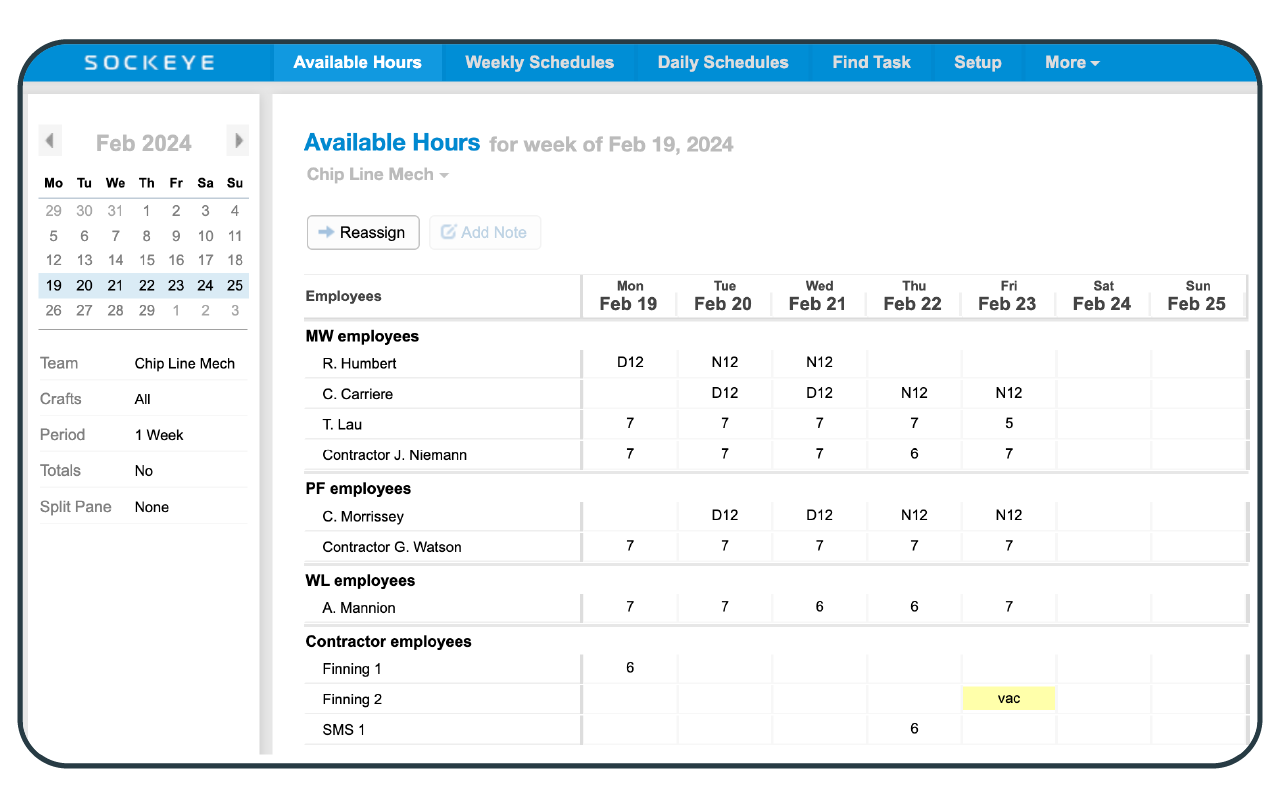

Real-time labor availability dashboard

Sockeye gives you a live view of how much time each technician, team, or contractor actually has available. Equally important, it gives you an easy way to keep those hours up to date — simply define your shift patterns, and then update individual capacity as needed (for sick days, training, vacation, etc.).

As you assign jobs, Sockeye gives you a live, color-coded view of your teams’ capacity. This integration between assignments and availability allows you to confidently schedule work that will fill out your team’s capacity, without going into overtime.

Sidenote: If you need to schedule overtime, Sockeye will not stop you from doing that. It will just give you a simple visual indicator that lets you know you are running OT.

No more overbooking individuals or shifts without realizing it. The result: overtime starts to drop naturally because your plan finally matches your true capacity.

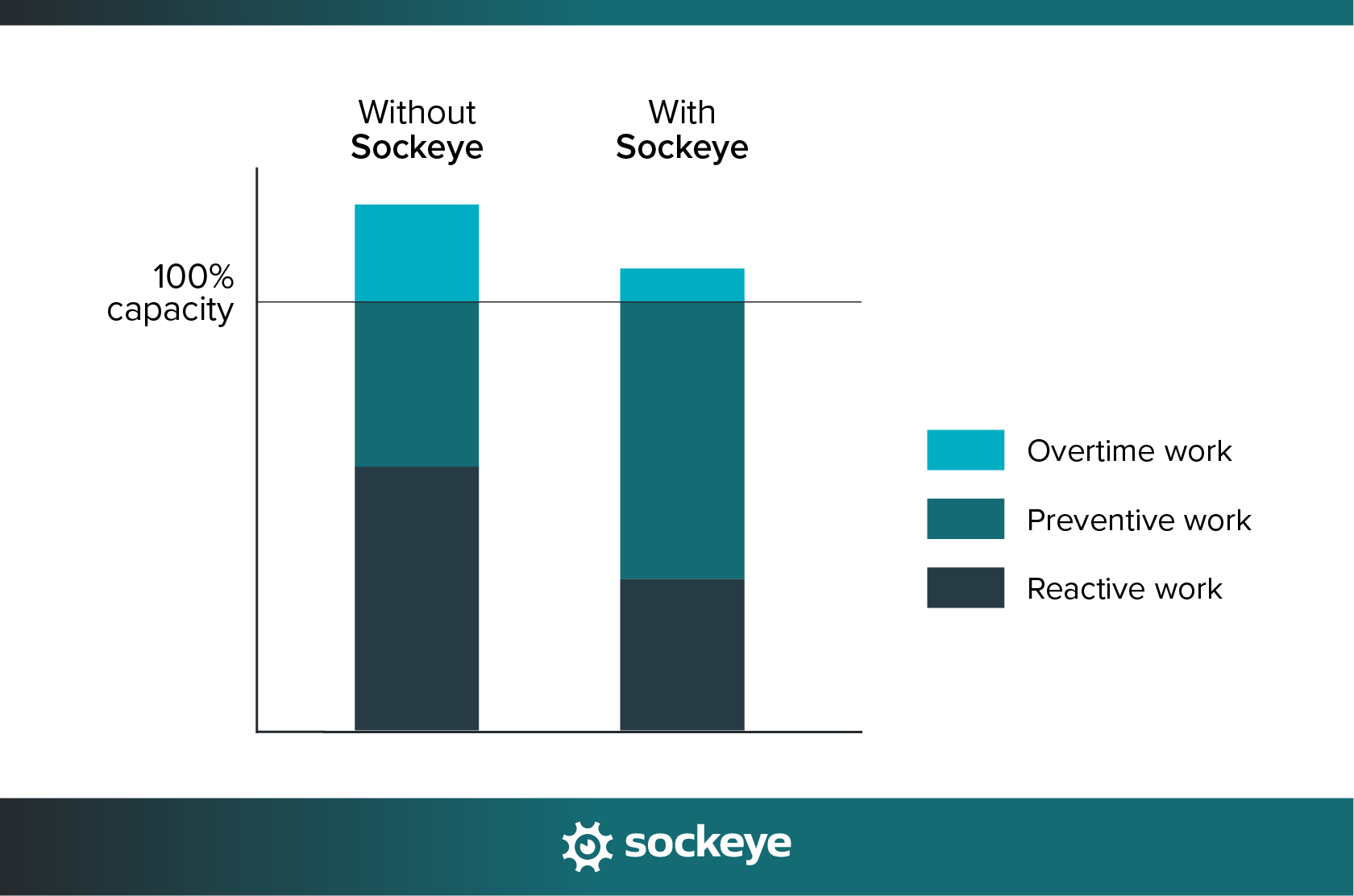

Furthermore, when you start executing preventive work more consistently, you slowly reduce emergency work. This leaves additional room in the schedule to catch up on backlog or do even more preventative maintenance.

Balanced workloads between crews and contractors

When you know everyone’s capacity, it’s easier to spread the work evenly.

This balance helps keep morale high and prevents the same “go-to” people from being stuck with extra hours every week.

Improved job planning

Sockeye’s scheduling automation and drag-and-drop (re)scheduling free up hours of planner time. Since many plants combine planner and scheduler into a single role, that means more time spent on proper job planning — getting materials ready, clarifying scopes, providing detailed instructions, and coordinating work with Production and Operations.

Teams using Sockeye, like Additya Birla Group, have seen overtime hours drop while completing more planned work and preventive maintenance.

KPI tracking

Sockeye’s built-in KPI dashboards help you spot trends before they become problems. You can track many different things that might be relevant for reducing overtime, like:

- Labor utilization for crews, contractors, and individuals

- Track the amount of planned vs reactive work done

- The size of your backlog

- Maintenance schedule compliance

- Reasons why work gets delayed (helpful in identifying systematic issues that might also cause overtime).

With that visibility, teams can continuously improve instead of reacting after the fact.

Other proven ways to reduce maintenance overtime

Smarter scheduling is the best place to start — but it’s not the only lever you can pull. Below are other proven strategies you can put to work right away.

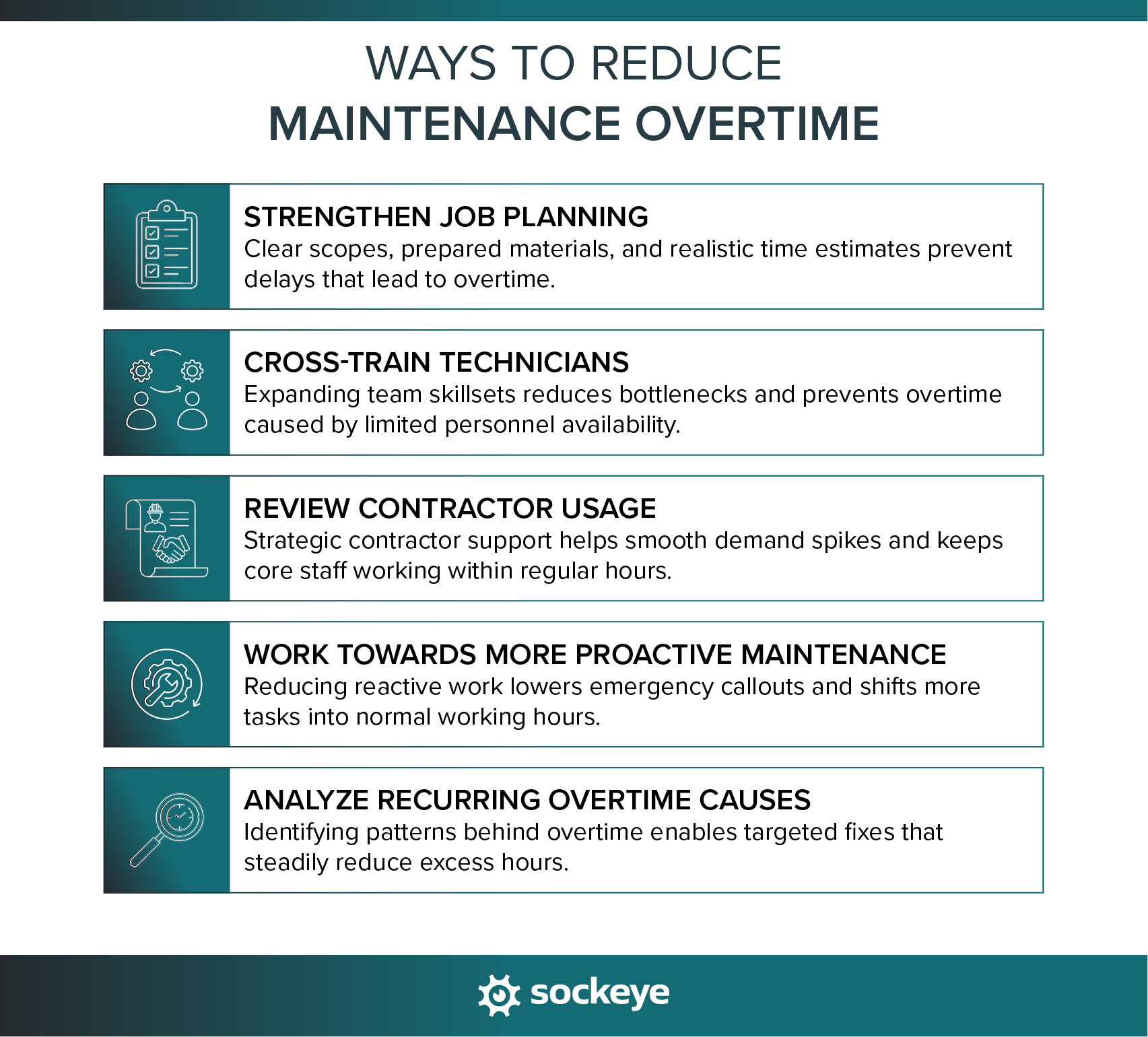

1. Strengthen job planning

Good work order planning saves hours before the wrench even turns. Many overtime issues start because jobs take longer than expected — usually due to unclear scopes, missing parts, or last-minute surprises.

A strong planning process should cover:

- Clear job scopes: Everyone knows what “done” looks like.

- Ready-to-go materials: Tools, parts, and permits are all in place before the job starts.

- Realistic time estimates: Based on historical data and operational realities, not best-case scenarios.

When planners have time to prep properly, technicians can execute without delays — keeping jobs within their planned hours and off the overtime clock.

2. Cross-train technicians

Overtime spikes when only a few people can do critical tasks. Cross-training gives your team more flexibility to handle absences, sudden breakdowns, or competing priorities.

Start small:

- Pair less experienced techs with veterans on complex jobs.

- Create quick-reference guides, one-point lessons, and maintenance SOPs for recurring tasks.

- You can also encourage job shadowing, but be aware that the quality of knowledge shared will be highly dependent on the mentor (which may or may not follow best practices in their daily work).

You can also upskill machine operators to handle simpler tasks like lubrication, cleaning, and certain inspections. That frees your technicians to focus on higher-skill work. At a minimum, the operators should know how to recognize and report equipment issues.

3. Review contractor usage

Contractors shouldn’t just be a “panic button” when things get behind. Used strategically, they can help you smooth out peaks and keep your internal team focused on core work.

A few best practices:

- Plan ahead for seasonal demand: If you know a shutdown or outage is coming, line up contract labor early.

- Use contractors for niche skills: Let them handle specialized tasks you can’t cover in-house. Do consider upskilling your technicians in the long run.

- Balance internal vs. external: Track where your hours go — if contractors are covering routine work, it might be time to revisit staffing or training.

Typically, the goal should be to create breathing room so that your full-time team isn’t constantly working overtime.

4. Work towards more proactive maintenance

A reactive culture guarantees overtime. When you’re always in “firefighting mode,” planned work gets bumped, and callouts never stop.

Shifting toward proactive maintenance doesn’t happen overnight, but small steps add up:

- Tighten up preventive maintenance (PM) schedules: Make sure PMs are actually being completed on time.

- Use condition-based triggers: Install simple sensors on critical equipment to catch issues early. This helps prevent downtime, but also gives you more time to plan work and adjust the schedule.

- Track failure patterns: If certain assets keep breaking, review root causes and work on addressing them systematically.

Fewer breakdowns mean fewer emergencies — and more time to do the work during regular hours.

5. Analyze recurring overtime causes

Don’t treat overtime as random — it usually follows a pattern. Regularly review your data to spot where it’s coming from:

- Which assets drive the most after-hours work?

- Do certain shifts or departments always run long?

- Is planned work consistently under- or overestimated?

Use that insight to adjust staffing, rebalance workloads, or refine your planning standards. Even a few small tweaks can have a big impact on total overtime hours over time.

Build a smarter, more predictable maintenance operation

Cutting overtime doesn’t mean asking your team to do more with less — it means making sure every hour counts. With real visibility into your labor capacity, better planning, and a more proactive maintenance culture, this becomes a much easier endeavor.

The payoff is big:

- Teams stay balanced and less burned out.

- Supervisors get more predictable costs and schedules.

- Work gets done on time — without constant weekend shifts.

- Consequently, you reduce maintenance overtime pay, getting back the budget for asset replacements or other initiatives.

If your maintenance team is stuck in an overtime cycle, it may be time to explore how more balanced workloads and simpler scheduling can save your team from drowning.

Learn more about Sockeye and start building a smarter, more predictable maintenance operation.