WINERY MAINTENANCE SCHEDULING SOFTWARE

Simplify Scheduling and Maximize Uptime at Your Winery

Stay on top of routine maintenance to prevent equipment failures, reduce unplanned downtime, and meet strict sanitation standards. Sockeye helps you build schedules in seconds, keep crews aligned, and respond faster to unexpected breakdowns.

Trusted by wineries across the globe

We built a scheduling tool so intuitive and efficient, it takes just one hour to learn — and 98% of wineries who try it keep using it to manage maintenance long-term.

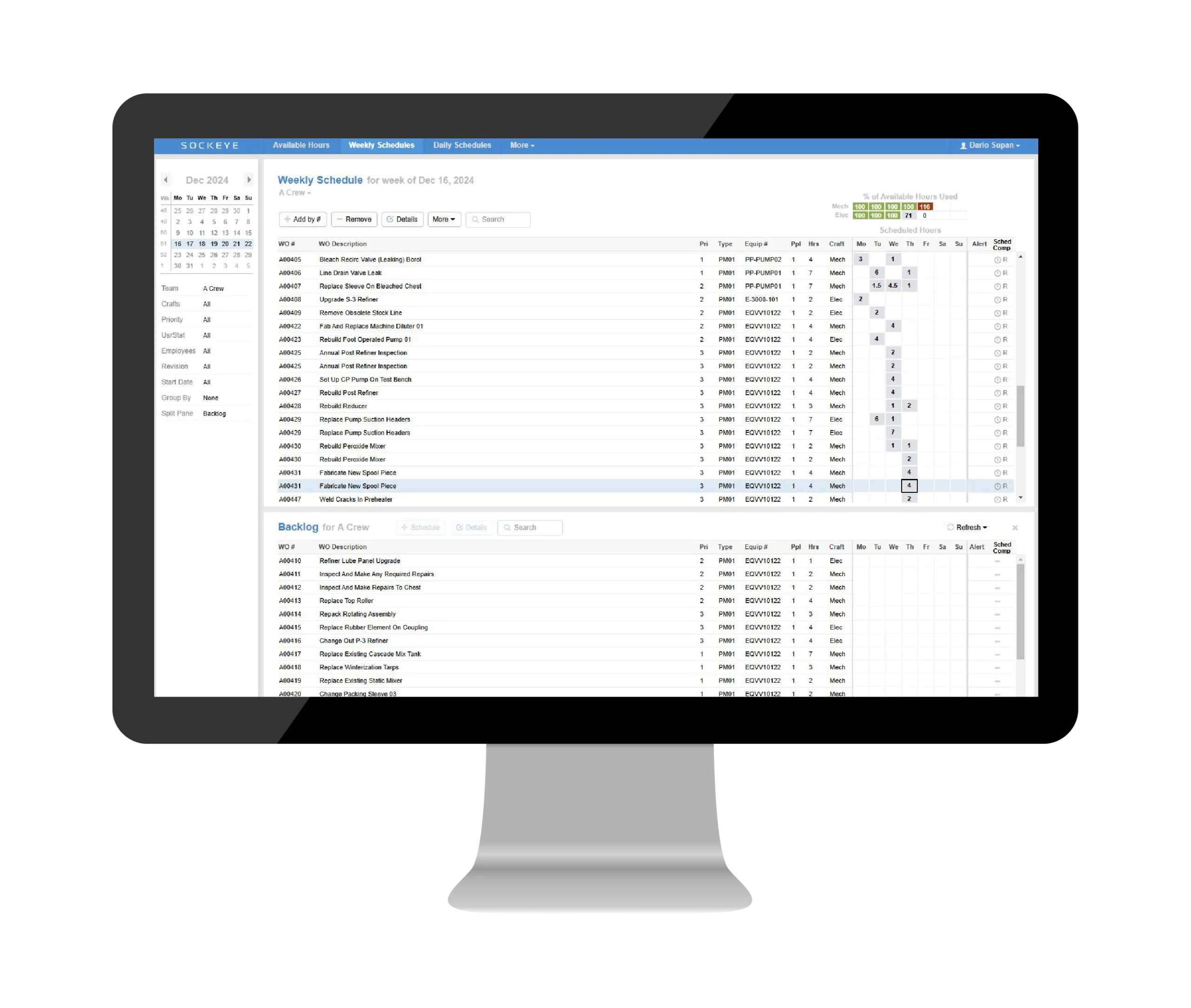

Here’s how Sockeye works

KEY FEATURES

Automatic scheduling

Schedule visualization

Work order status tracking

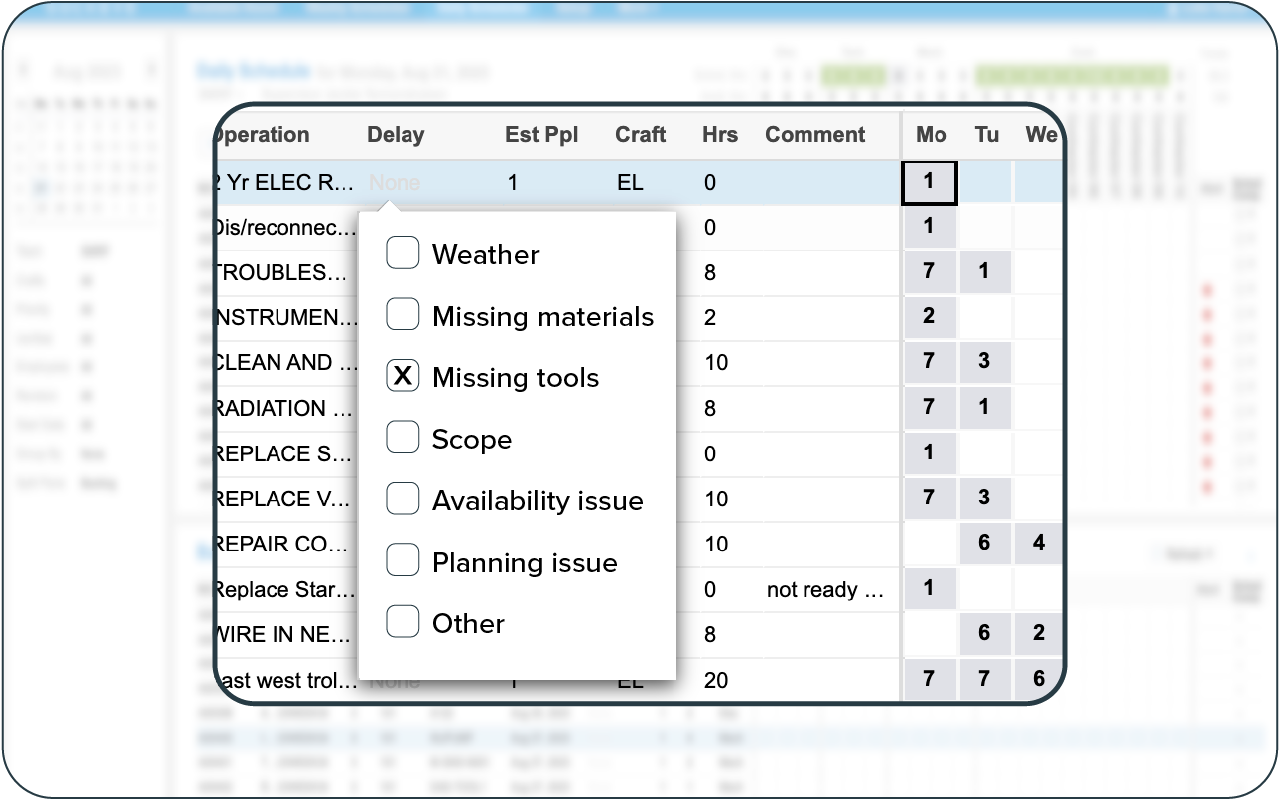

Delay reasons tracking

SMRP and custom KPI reports

Full CMMS/HR system integration

Perfect for

Wineries that have a CMMS or EAM

Sockeye works best as a CMMS add-on. If your team struggles to schedule work through existing software, use Sockeye’s intuitive interface instead.

Teams that need to do more with less

Complicated scheduling kills productivity. Our automation and availability data help you schedule more work by balancing workload between crews.

Simpler & more efficient scheduling

Sockeye is a purpose-built scheduler that’s easy to implement and even easier to use. Its focused on maintenance scheduling — and damn good at it.

Test Sockeye for 30 days.

No IT involvement required.

Confirm user adoption and get a proof of concept before spending a single cent.

TAKE THE FREE TRIALPM SCHEDULING

Automate preventive maintenance scheduling

Stay on top of routine tasks like equipment cleaning, tank inspections, lubrication, and filter changes by building consistent weekly and daily schedules in just a few clicks.

Share live schedules to keep your frontline teams aligned and accountable. Easily reschedule work by dragging and dropping tasks to the next available slot.

LABOR AVAILABILITY

Do more with a tight budget

With real-time crew and contractor availability, Sockeye helps you level workloads and schedule teams near full capacity. When schedules get tight — like during harvest or bottling — you’ll know exactly where you can shift work without adding overtime.

“Sockeye identifies where deficiencies are in your man hours. For instance, if Crew A is 40 hours over schedule, but Crew B is only 35% scheduled, you can move your resources to level it out to avoid overtime pay. That saves you money.”

Todd Hicks, Planning and Shutdown Superintendent at the AV Group

EQUIPMENT RELIABILITY

Prevent downtime with smarter scheduling

From chillers and pumps to bottling lines and fermentation controls, Sockeye helps you keep critical winery equipment running by making preventive maintenance easier to schedule — and harder to overlook

Track delay reasons for PMs and WOs, free up time to prepare jobs properly, and reduce the risk of breakdowns that disrupt production.

KPI REPORTING

Track the metrics that matter

Automatically generate SMRP and custom KPI reports to track schedule compliance, labor utilization, reactive vs preventive ratios, and backlog trends — then freely feed that data into your BI tool.

Track how specific work orders impact reliability and get a clear picture of the effectiveness of your current maintenance schedule.

REGULATORY COMPLIANCE

Stay audit-ready with a documented schedule

Winery compliance relies on documented and timely maintenance. Sockeye creates a digital trail, so you’re always ready for audits and inspections.

Build schedules your team can adhere to, and always know what’s been done, what’s in progress, and what’s due next — all in one place.

Schedule more work.

Get more work done.

Let us help you create a highly productive maintenance team.

Book a DemoWinery maintenance best practices

Keeping equipment clean, compliant, and reliable in a winery requires consistent planning, smart scheduling, tight coordination, and the right tools. The best-run wineries treat maintenance as a strategic function — not just a reactive one.

The following best practices will help your team reduce downtime, maintain sanitation standards, and extend the life of critical assets.

1) Schedule maintenance around production cycles

Wineries follow a natural rhythm: crush, fermentation, aging, bottling. Each stage puts different pressures on equipment and space, forcing maintenance to compete with production priorities.

To reduce disruption, schedule your most resource-intensive work — deep cleans, inspections, corrective repairs — during slower windows, such as post-harvest or between bottling runs. During busy seasons, stick to fast, low-risk tasks that can be slotted in without slowing production. You can also:

- Use production data to predict low-activity windows for PM work.

- Create maintenance blocks in your production calendar to protect time.

- Prioritize PMs for equipment that will be idle during specific phases.

With a little planning and foresight, maintenance becomes a supporting player — not a bottleneck — in your production flow.

2) Align maintenance with crew shift patterns

Many winery crews operate on rotating shifts, especially during harvest or bottling. Maintenance staff often overlap with cellar or production teams — or wear multiple hats. That makes visibility into labor availability essential.

Instead of relying on static calendars or guesswork, build your maintenance schedule around actual shift data. This allows you to:

- Visualize crew capacity across shifts and avoid overloading teams.

- Distribute tasks based on skill sets and availability, not just assumptions.

- Balance internal labor with seasonal help and contractor resources.

Smart scheduling respects your crew’s time and ensures critical work gets done — even when staffing is tight.

3) Prioritize cleaning and sanitation tasks

Sanitation isn’t just a food safety requirement — it’s a make-or-break factor for wine quality. Tanks, hoses, filters, barrels, and bottling lines all need regular, well-documented cleaning to prevent contamination from wild yeasts, bacteria, or chemical residues.

Treat these tasks as non-negotiable preventive maintenance. Use your scheduling system to assign, track, and confirm sanitation steps just as you would with mechanical inspections or repairs. Automating reminders and follow-ups ensures nothing gets skipped during busy periods or staff transitions.

4) Maintain environmental systems year-round

Fermentation and aging environments require stable temperatures and humidity. If glycol chillers or HVAC systems fail, you could lose a tank — or a vintage.

Rather than waiting for issues to surface, proactively maintain these systems by:

- Scheduling inspections ahead of seasonal transitions.

- Replacing air filters and checking sensors regularly.

- Calibrating temperature control systems before they’re heavily relied on.

A few hours of preventive work can protect months of careful winemaking.

5) Use a live schedule to coordinate across departments

In most wineries, maintenance competes with cellar work, production demands, lab tests, and deliveries — all in shared spaces. A bottling room might be in use for production all day, but is needed for equipment repairs overnight. Without visibility into each team’s plans, conflicts are inevitable.

A live, centralized maintenance schedule gives all departments more clarity on what’s happening, when, and where. By coordinating in advance, you reduce disruptions, avoid double-booking resources, and make sure essential maintenance gets done on time — without teams stepping on each other’s toes.

6) Track delay reasons and work history to improve reliability

Every time a job gets pushed or skipped, there’s a reason. Maybe a part wasn’t in stock, or production ran long. But unless those reasons are documented, the same issues will keep happening.

Make delay tracking part of your workflow by:

- Logging every delayed task with a reason code (e.g., labor, parts, production).

- Reviewing delays weekly or monthly to identify trends or bottlenecks.

- Using delay insights to refine your planning, scheduling, staffing, or inventory practices.

With better visibility into what’s holding you back, you can start making reliability gains that actually stick.

CMMS/EAM SCHEDULING BOLT-on

Simplify winery maintenance planning and scheduling

Tired of bouncing between your CMMS, whiteboards, and shift notes — while work is still falling behind? Sockeye is built to keep up with the pace, complexity, and coordination required in modern winery operations.

BOOK A DEMOStep 1

Get a Customized Demo

We start with a call from one of our product specialists to understand your specific needs. We then run a customized demo with your entire team so you can see how Sockeye makes scheduling easy.

Step 2

Start Your Risk-Free Trial

Test drive Sockeye using a file-based integration (Excel). This requires no investment or IT resources and just a few hours from the scheduler. Verify that Sockeye is right for you before you go all in.

Step 3

Get the Most out of Your Team

No more disjointed scheduling, missing data, & flying blind. Consistently build daily/weekly schedules, check the latest status, and maximize preventive maintenance by maximizing productivity.

Frequently Asked Questions

Sockeye uses two primary types of integration:

1. API-Based Integration

Sockeye uses API-based integration to adapt to every enterprise’s unique needs, providing customized read/write configurations with your maintenance and/or HR systems. This means that any last-minute changes made in your CMMS are reflected in Sockeye — and vice versa.

2. File-Based Integration

Sockeye uses an Excel template to port data between the CMMS and Sockeye — simply export your CMMS data into Sockeye’s Excel template and click ‘refresh’ to update your data. The implementation requires minimal effort and no IT resources or custom coding.

Learn more about integration types

A full production rollout with API integration takes 4 to 6 weeks, while a file-based integration can be done in under 2 weeks.

Sockeye’s experts handle most of the integration work; your IT team just needs to provide access (API endpoints or database views) and some oversight. Because Sockeye is cloud-based, there is no server to install or software to maintain on-premises — it’s all handled by our cloud infrastructure.

Yes, Sockeye offers a one-month trial using our file-based integration. You’ll get access to all of Sockeye’s features and support throughout the trial. To get started, share an Excel file of your schedule and join a 1-hour training session.

Sockeye supports read/write CMMS integration. The exact data exchanged typically includes work order details, scheduling fields, and resource info.

Configurations can be customized as read-only or selective write-back to accommodate your IT/security policies.

Work orders are updated according to your requirements. Typically, work orders are automatically updated when the scheduled work order end date has been reached. Work order updates made in your CMMS and Sockeye are automatically synchronized in both systems.

Sockeye allows you to input your technician and contractor shift patterns to track labor availability. You can easily edit labor availability for vacations, training, etc, with a couple of clicks.

Yes, Sockeye integration is customized according to your unique scheduling and IT requirements. Read/write integration, read only, write only specific fields, etc. — Sockeye is designed to meet your enterprise’s unique integration requirements.

We take data security very seriously. Sockeye is hosted on Microsoft Azure, which has industry-standard certifications (like ISO and SOC 2). Data is always encrypted, and backups are stored in a separate geographic region.

On the access side, we support role-based user permissions, SSO (Single Sign-on), and 2FA (two-factor authentication).

From Fortune 100 enterprises to single-site enterprises, Sockeye is ready, vetted, and prepared for your IT security review.

Learn more about Sockeye’s security

Schedule more work.

Get more work done.

Let us help you create a highly productive maintenance team.

BOOK A DEMO