Poor preventive maintenance compliance often results in more emergency work, creeping overtime, frustrated technicians, and reduced equipment uptime.

While PM compliance is often tracked, it is not always understood — or used well. Some teams chase high percentages without realizing the number is misleading. Others ignore it altogether, focusing on other KPIs and metrics.

Today, we’ll break down what preventive maintenance compliance means, how to track and calculate it correctly, how to set realistic targets, and — most importantly — how to use it as a practical decision-making tool to improve asset reliability.

What is preventive maintenance compliance?

Preventive maintenance compliance (PMC) measures how consistently PM work is completed by the required due date.

In general, PM compliance can be used to:

- Monitor whether your preventive maintenance schedules are being followed.

- Identify scheduling and planning breakdowns.

- Highlight risk exposure on critical assets.

- Support reliability and maintenance maturity discussions.

When tracked correctly, it’s an early warning signal for reliability risk. When tracked poorly, it becomes a feel-good number that hides real problems.

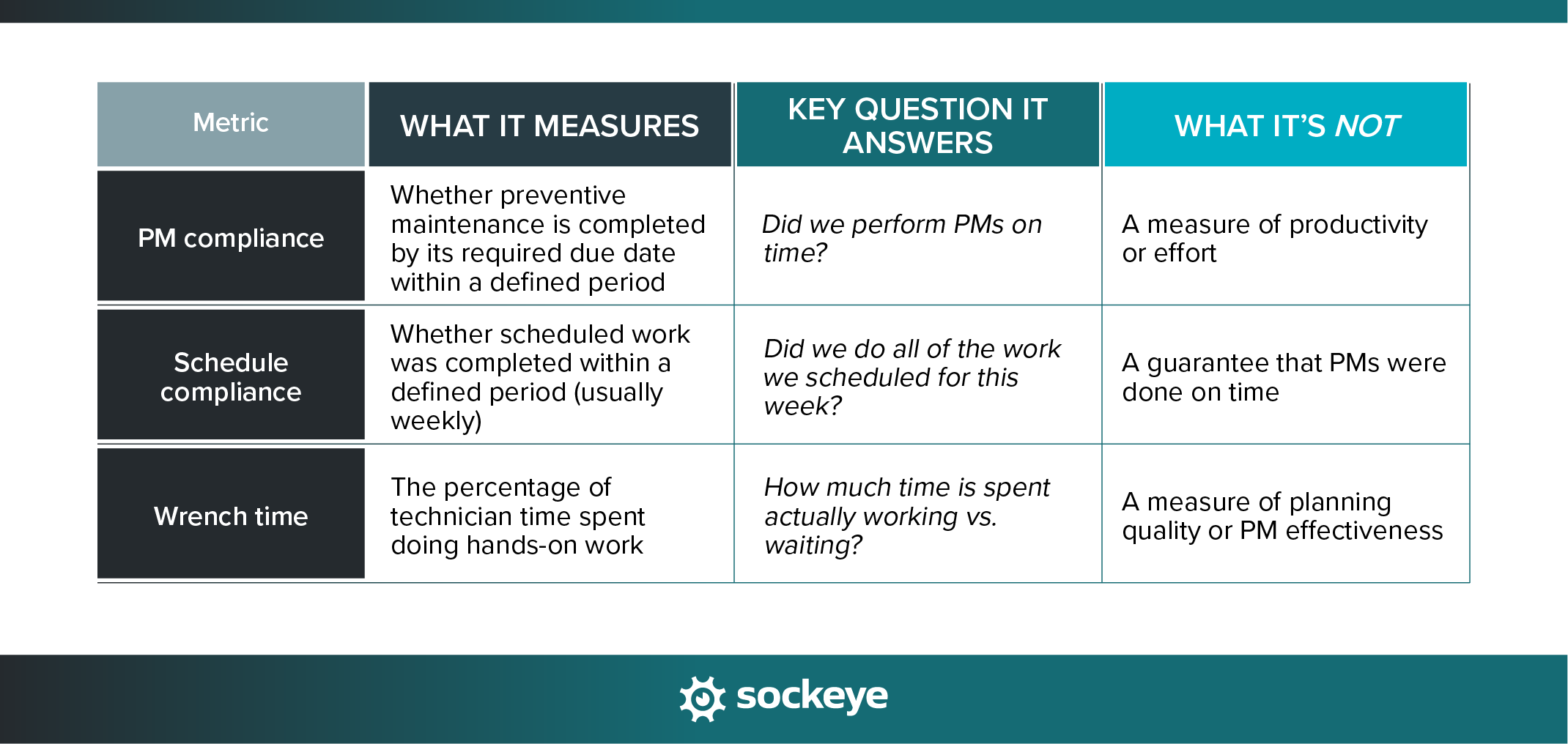

PM compliance vs. schedule compliance vs. wrench time

These terms can sometimes get mixed up, but they measure different things:

- PM compliance: Were preventive work orders completed by their required due date?

- Maintenance schedule compliance: Did the crew complete all scheduled work (preventive, corrective, emergency) for a given period?

- Wrench time: How much of a technician’s time is spent doing hands-on work versus waiting, searching, or traveling?

A team can have high schedule compliance but poor PMC (and vice versa). Likewise, strong wrench time doesn’t guarantee PMs are being done on time. Each metric tells a different part of the story.

Common misconceptions

One of the most common misunderstandings is: “If the PM is closed, it’s compliant.”

Closure alone doesn’t mean compliance. A PM completed days or weeks late still exposes the asset to risk during that gap.

Other bad practices include:

- Counting rescheduled PMs as compliant.

- Excluding overdue PMs from reports to “clean up” the number.

- Treating all preventive work as equally important, regardless of asset criticality.

All of these practices inflate compliance and reduce trust in the metric.

Sidenote: Preventive maintenance compliance is not meant to measure technician productivity or overall maintenance efficiency — those are different metrics with different purposes.

When PM compliance becomes a misleading KPI

PM compliance becomes dangerous when it’s:

- Used as a performance target without context.

- Reported as a single monthly number with no trend analysis.

- Disconnected from failures, backlog, or emergency work.

In these cases, teams tend to optimize the metric instead of the maintenance system — deferring work, shortening PM windows, or closing tasks without proper execution.

How to track PMC effectively

Tracking PM compliance doesn’t require complex analytics — but it does require clean data. Poor tracking and data entry discipline is your biggest enemy here.

At a minimum, you need three things for every PM work order:

- Work order type (clearly identified as preventive maintenance)

- Required due date (when the PM should be completed)

- Actual completion date (when the work was finished)

Most teams track PM compliance using spreadsheets or a CMMS/EAM system. You can also track it using a dedicated maintenance scheduling tool like Sockeye, but more on that later.

PM compliance works best when reviewed regularly. Common approaches include weekly reviews for schedule discipline and monthly reporting for management.

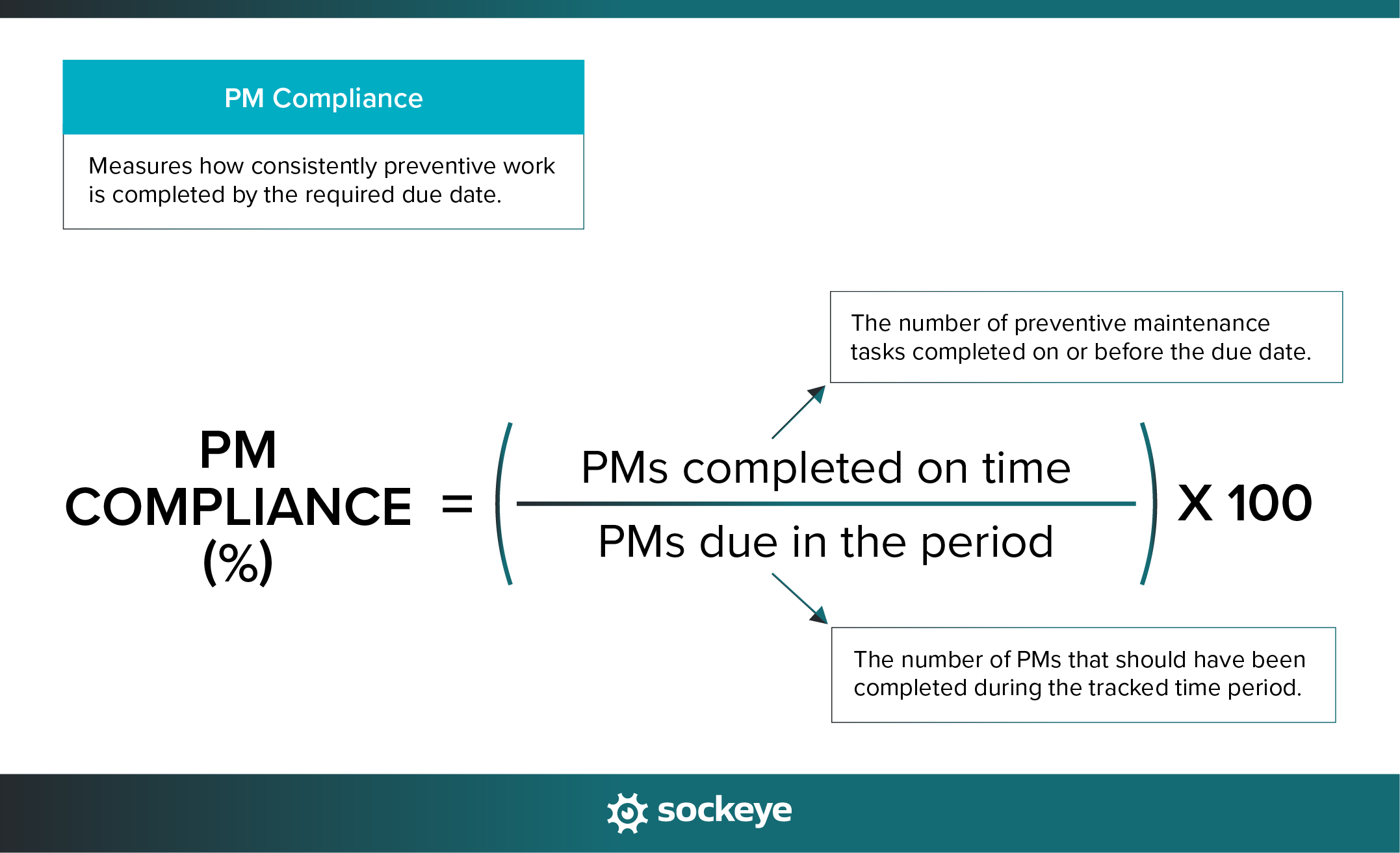

How to calculate PM compliance

PMC calculations are simple on paper — but small rule changes (what counts as a PM, is the calculation for a specific asset or location, etc.) can dramatically change the result. That’s why it’s critical to define your method clearly and stick to it when benchmarking trends.

The most common formula is:

PM Compliance (%) = (PMs completed on time ÷ PMs due in the period) × 100

Example: Let’s say you had 120 PMs in January, and 96 were completed on schedule.

PM Compliance = (96 /120) x 100 = 80%

Watch out for these common mistakes that inflate results:

- Counting PMs as compliant because they were eventually completed.

- Resetting due dates to avoid overdue status.

- Only measuring PMs that made it onto the weekly schedule (this one is debatable; just be consistent in what you measure so you can compare apples to apples).

- Counting PMs that were performed partially or incorrectly as “Done”.

Setting the right PM compliance targets

This can be tricky. Set them too low, and risk creeps in quietly. Set them unrealistically high, and teams start gaming the system just to hit the number.

What is the realistic target for your organization? Hard to say, as benchmarks vary by industry and asset mix. Broadly speaking:

- Below 60%: Implies serious issues with your preventive maintenance program.

- 60–80%: Indicates preventive maintenance execution issues and elevated reliability risk.

- 80–90%: Generally acceptable for many operations.

- 90–95%: Strong discipline, often seen in mature maintenance organizations.

Targets above 95% are possible — but usually only for short periods or tightly controlled environments. After all, emergencies will happen, production priorities will shift, and resources will be constrained.

If your preventive maintenance compliance is low, you need to aim for incremental improvements and start making systematic changes.

If you have trouble setting realistic targets, remember that PM compliance should support reliability. Ask:

- Which assets create the most downtime when they fail?

- Which PMs actually prevent those failures?

- Where does missed preventive work translate into real business risk?

You can use this exercise to set different compliance targets based on asset criticality and regulatory requirements. When the time comes, this will also help schedulers decide which preventive work to prioritize vs delay.

Practical tips for improving preventive maintenance compliance

The biggest gains usually come from better planning, clearer roles, and more stable schedules. Here are some strategies to consider:

- Improve job planning and kitting: PMs should be ready-to-execute before they’re scheduled. Clear task steps, estimated labor, tools, and pre-kitted parts reduce delays that push PMs past their due dates.

- Improve scheduling discipline: Build schedules based on actual labor availability, not best-case assumptions. Balance the workload across teams to avoid overloading specific shifts or weeks and repeatedly rolling PMs forward.

- Right-size PMs (optimize, eliminate, consolidate): PMs that are too frequent or too intrusive are the first to be skipped. Review PM frequency regularly to remove low-value tasks and combine work where it makes sense.

- Write SOPs for common PM tasks: Standard procedures reduce variability and rework, especially for common routine work. Consistency improves execution speed and quality.

- Increase schedule stability: Constant schedule changes erode PM compliance. Protect the weekly schedule from unnecessary break-ins and limit mid-week reshuffling.

- Improve spare parts availability: Missing parts are a common cause of late PMs. Align min/max levels and kitting practices with preventive maintenance plans, not just reactive work.

- Clarify roles between operations and maintenance: PMC suffers when asset access isn’t clearly owned. Define who is responsible for equipment availability, lockout support, and production coordination.

- Shift from reactive to proactive work: The more time spent firefighting, the less time you have to execute PMs. Reducing emergency work frees up the capacity needed to perform preventive work.

PM compliance as a decision tool

As mentioned earlier, preventive maintenance compliance should be tracked over time. So focus on trends, not snapshots. Track PM compliance alongside:

- Backlog growth

- Number of equipment failures for assets on a preventive plan

- General schedule compliance

- Total hours spent on preventive vs reactive work

Low PM compliance is often the result of deeper issues: too much reactive work, aging assets, not enough technicians, misaligned production priorities, etc. In these cases, forcing compliance back up won’t fix the system. The real value comes from asking why PMs are being missed — and addressing those root causes.

Use Sockeye to improve scheduling and schedule adherence

PM compliance should never be treated as a box-checking exercise. At its best, it’s a reflection of how well maintenance work is planned, scheduled, and protected from daily disruptions. When compliance slips, the issue is rarely technician effort — it’s often the schedule itself.

This is where a scheduling CMMS bolt-on like Sockeye changes the equation. It helps organizations:

- Bring clarity, structure, and consistency to how work is scheduled, across teams and locations.

- Vastly simplify the maintenance scheduling and rescheduling process, freeing up time that your planners can use to create better job plans.

- Build realistic, capacity-based schedules.

- Protect preventive work from being pushed out by reactive tasks.

- Improve schedule visibility and accountability.

- Automatically calculate preventive maintenance compliance and generate weekly/monthly custom reports, which can be forwarded to your BI software.

When scheduling improves, PM compliance follows — and reliability improves with it.

Want to learn more about Sockeye? Start by checking out its preventive maintenance scheduling capabilities.