Every maintenance planner knows the struggle: trying to build a fair, realistic schedule when half the data you need is scattered across spreadsheets, emails, or sitting in someone’s head. One crew ends up buried with work while another is on cruise control.

Balancing workloads is critical for maintenance efficiency and productivity. Teams that run too hot burn out, make mistakes, and cost more in overtime. Teams that run too light waste labor hours that could have been spent tackling backlog or preventive work.

Sockeye scheduling bolt-on is the remedy for this exact headache. It gives planners and schedulers a real-time view of crew and contractor availability so they can spread the work evenly, get more work done, and stay on schedule

Why accurate labor availability data matters

Parkinson’s Law says: “The amount of work assigned will expand to fill the time available.”

That is why it’s best to load technicians close to 100% of their available capacity. If a crew has 400 hours of labor available, giving them just 200 hours of scheduled work almost guarantees those 200 hours will stretch to fill the week.

On the other hand, scheduling them for the full 400 hours pushes the team to get more done, even if not every task is completed. As Doc Palmer, author of Maintenance Planning and Scheduling Handbook, explains:

“A 10-person crew with 400 hours of labor capacity available that starts with a weekly schedule of 400 hours of specific work orders will complete more work than normal, even if it does not complete all the scheduled work.”

The problem is visibility. Most planners don’t have a clear picture of who’s available. Data lives in spreadsheets, HR files, or not at all. That leaves schedulers guessing, overestimating, or wasting hours hunting down the numbers they need.

Add to that the complexity of scheduling and rescheduling in a standard CMMS or EAM software, and no wonder techs will be scheduled below capacity — it’s just easier to maintain the schedule that way.

Ultimately, without accurate labor availability data, “balanced workloads” are just wishful thinking.

How Sockeye helps you track contractor and crew availability

Maintenance planners and schedulers need to know when contractors are onsite, how many hours each crew can give, and when changes happen.

Sockeye makes that possible. Here’s how.

Sockeye’s available labor dashboard

Sockeye is a simple scheduling bolt-on that integrates with any popular CMMS or EAM software. If your team struggles to schedule work consistently using your existing maintenance software, they can do it through Sockeye’s intuitive interface instead.

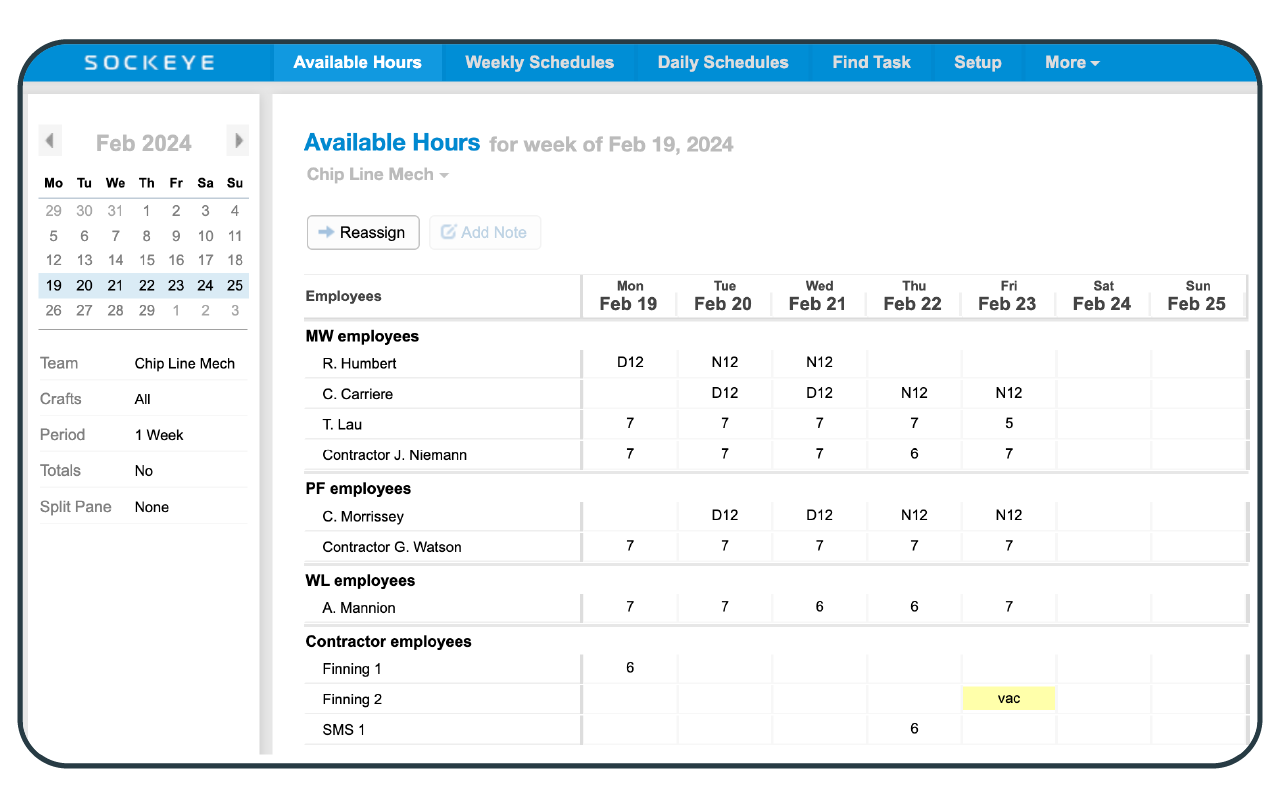

A core part of the maintenance scheduling process is our labor availability dashboard, which displays real-time crew and contractor availability.

Sockeye can populate that dashboard in three different ways:

- Pulling directly from your CMMS/EAM: If you already track availability there, Sockeye syncs it automatically.

- Editable shift patterns: Every technician’s hours are pre-populated based on your current shift patterns. These can be quickly reviewed or updated before weekly scheduling begins.

- Integrating with HR software: Sockeye can also pull vacation, leave, and other updates from your existing HR software to keep the availability data up to date.

The third option is the most popular one, as most maintenance departments do not track availability in other software.

With everything in one place, it takes minimal effort to keep the availability data current. Plus, you get visibility across all teams and contractors for accurate resource leveling.

Using technician availability to balance workload between teams

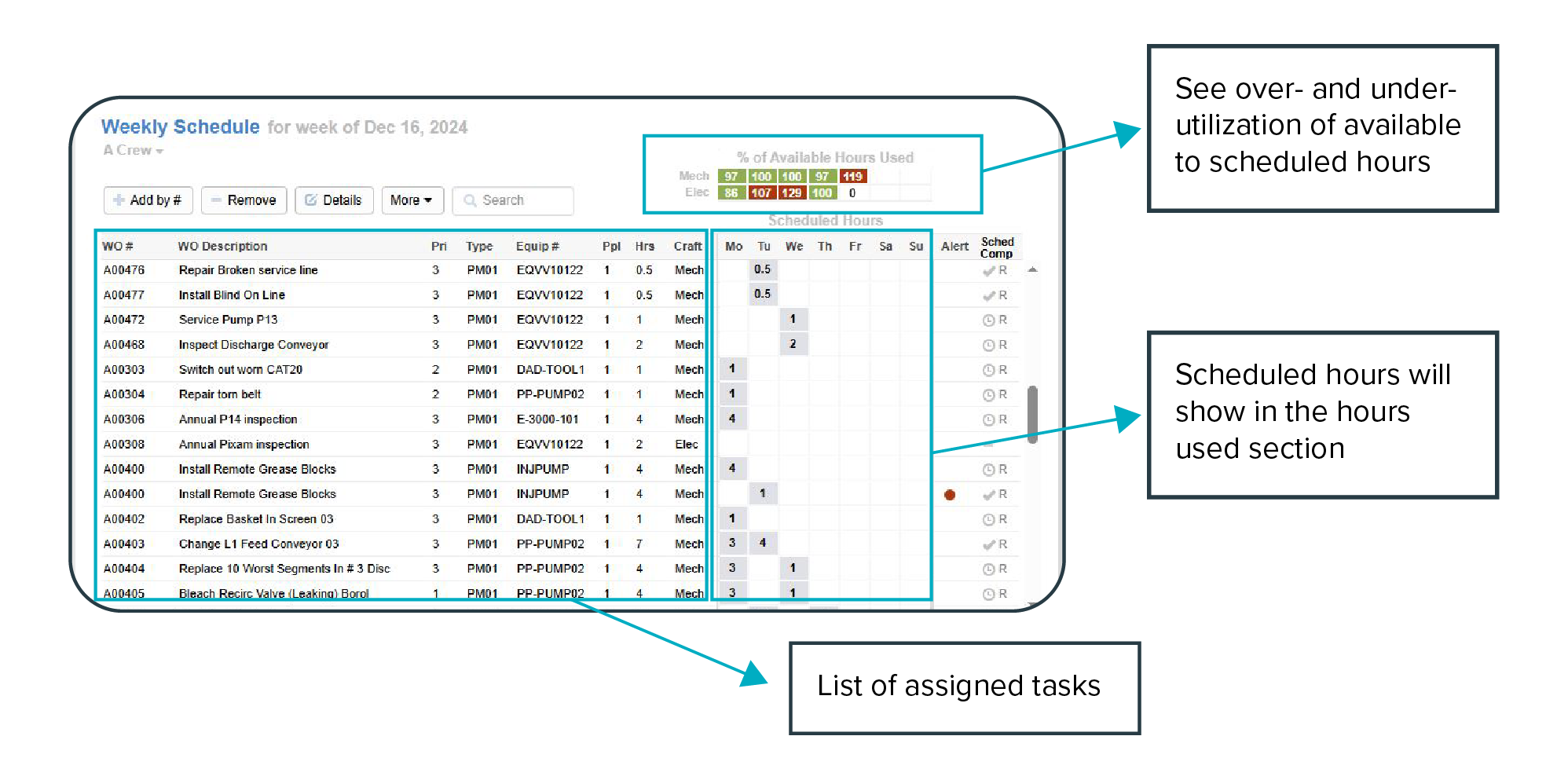

Sockeye will visually highlight gaps and excess capacity, so planners can see where one crew is overloaded and another still has room.

Take the above Crew A vs. Crew B example: if Crew A is scheduled 40 hours over capacity but Crew B is only 35% booked, Sockeye makes that imbalance obvious. With a few clicks, you can level workloads between teams and make sure every available hour is put to use.

Automating technician assignments based on skill and availability

Balancing workloads isn’t just about filling empty slots. The job at hand needs to be assigned to the person with the right skills. A pipefitter can’t cover an electrician’s task, and a mechanic’s hours shouldn’t be wasted on work outside their role.

That’s why Sockeye doesn’t just look at availability — it also respects skill sets. Each technician’s role is tied to the crew they belong to.

Using these two pieces of information, Sockeye can automate technician assignments based on skill and availability. Big maintenance teams use this automation to speed up their scheduling by up to 90% — weekly scheduling that once took them 10 hours can now be done in just 1 hour.

You just need to select the tasks in your backlog and click the “Schedule” button. Sockeye will create a ready-made schedule you simply need to review, tweak (if needed), and publish.

Rescheduling is just as easy. You grab the task and move it to the next available slot (or assign it to a different team).

We tried to build a system that mirrors how scheduling happens on a busy plant floor, so the process feels natural, not like fighting with software.

Signs your maintenance team needs better labor availability tracking

Watch out for these red flags:

- Overtime and backlog keep creeping up, even though you should have enough hours to cover all work.

- Your maintenance schedule compliance is staying flat or going down regardless of how much work you schedule that week.

- You often find teams or technicians sitting idle while others are buried in work.

- Schedulers are chasing data across spreadsheets, emails, or sticky notes.

- Vacations, leave, or contractor hours keep slipping through the cracks.

If these sound familiar, your team is probably flying blind. Balanced workloads are only possible when you have clear, real-time visibility into technician and crew availability — and a scheduling tool that makes it easy to track and act on that data.

That’s exactly what Sockeye delivers: faster, smarter, drag-and-drop scheduling that puts every available hour to work.

👉 Want to see our maintenance scheduling automation in action? Request a quick product demo with our team.