Are your planners and schedulers spending more time in Excel than SAP?

If so, you’re not alone — and it’s a sign that your maintenance scheduling process is due for an upgrade. Many companies still struggle with outdated workflows, clunky SAP-native tools, and manual workarounds that create more problems than they solve.

When your team is juggling spreadsheets, coordinating by email, and constantly chasing updates, it’s hard to keep schedules accurate, your people aligned, or your planners sane.

The good news? Tools like Sockeye can bolt onto your SAP and vastly simplify the whole maintenance scheduling process. But more on that later.

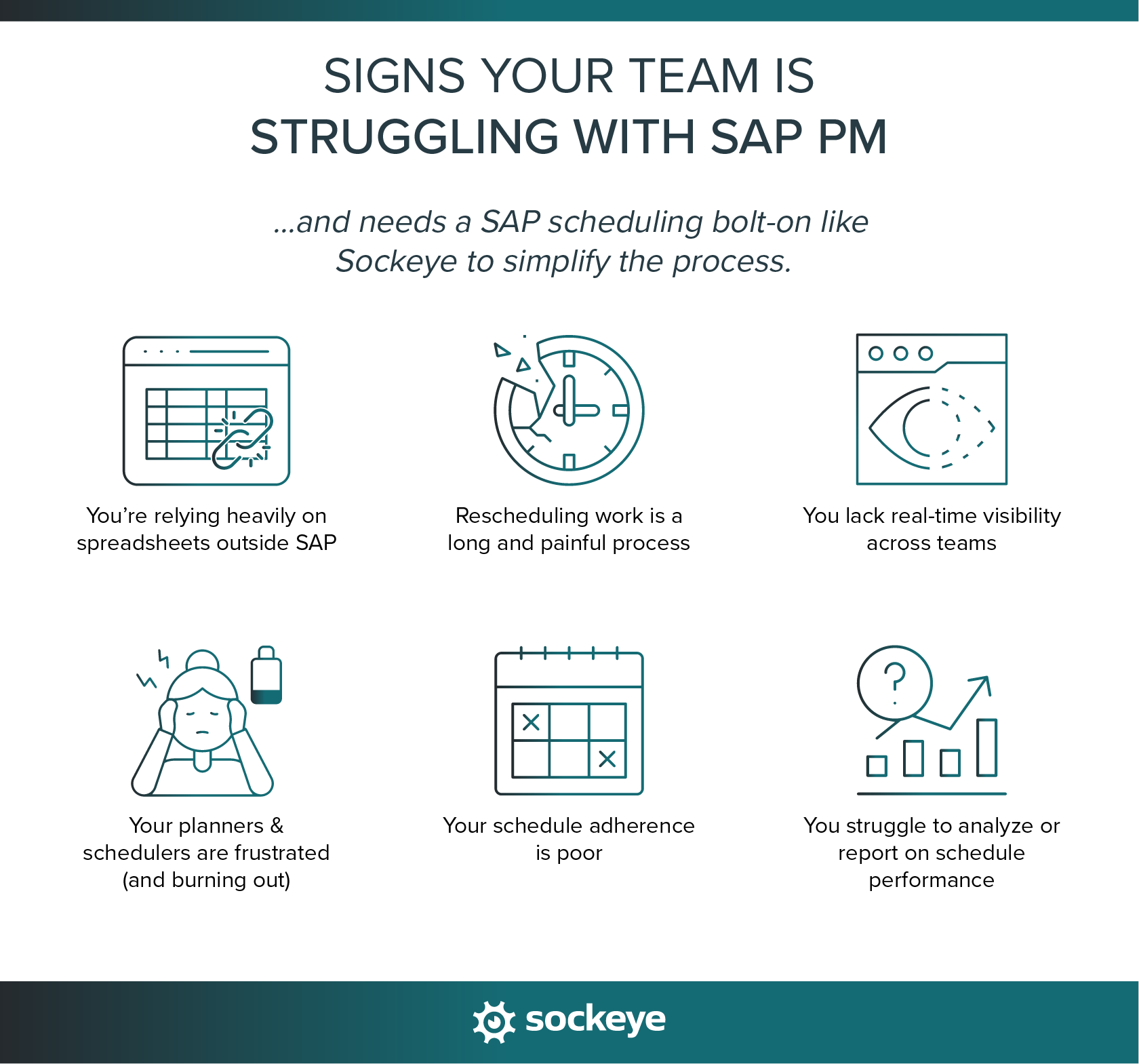

Here are the telltale signs that SAP PM makes your maintenance teams’ lives much harder than they need to be.

Sign #1: You’re relying heavily on spreadsheets outside SAP

Let’s be honest — if planners are spending half their day in Excel instead of SAP, that’s a red flag.

It usually starts small: exporting work orders to a spreadsheet “just to organize things better.” But before long, those spreadsheets turn into the real scheduling tool. Now you’ve got multiple versions floating around, manual updates that take hours, and a growing disconnect from the actual data in SAP.

The impact?

- Time wasted copying and pasting

- Difficulty visualizing the schedule

- Version control headaches

- A higher risk of errors

- Limited visibility into what’s been done, what was missed and what’s coming up

- And worst of all — an inconsistent schedule that is no longer synced with what’s really happening in SAP.

If your planners and schedulers constantly switch between systems and spreadsheets, it’s a sign that SAP’s built-in scheduling tools aren’t cutting it.

Sign #2: Rescheduling work is a long and painful process

If every little schedule change turns into a fire drill, your process isn’t working for you — it’s working against you.

In a busy production plant, plans shift. Equipment breaks down. A tech calls in sick. Priorities change. When your scheduling tool doesn’t flex with reality, every update becomes a mess.

What that looks like:

- Planners are stuck doing repetitive rework: Dragging jobs around in Excel, double-checking availability, re-exporting new versions of the schedule.

- No quick way to adjust the schedule: Simple schedule updates take way longer than they should.

- Work is getting delayed: Techs are either sitting idle, waiting for an updated version of the schedule — or on the way to the wrong asset because they didn’t get the update on time.

The result? Slow responses, more errors, and a team that spends more time planning and scheduling than doing the actual maintenance work.

Here’s the thing: If your tools don’t make it easy to pivot and re-balance the schedule, they’re just adding friction. Solutions like Sockeye bring in smart automation and drag-and-drop adjustments, so planners can make updates in seconds — not hours.

Sign #3: You lack real-time visibility across teams

Scheduling shouldn’t feel like a guessing game — but for many SAP PM users, it does.

When maintenance, operations, and other departments can’t see the same plan (or don’t trust the one that’s shared), things start to break down. Literally.

You’ll see symptoms like:

- Double-booked resources

- Preventive work getting delayed because of a collision with the production schedule

- Constant back-and-forth just to confirm who’s doing what and when

- A whole lot of finger-pointing when things go wrong.

This happens when schedules live in siloed tools or emails, and there’s no shared, up-to-date source of truth.

Tools like Sockeye bring clarity by syncing directly with SAP and offering a live, verified schedule —- one that’s easy to understand, and even easier to share.

Sign #4: Your planners & schedulers are frustrated (and burning out)

We worked with some great planners and schedulers when building Sockeye. But when the tools are clunky and the process is chaotic, even your best planners can get overwhelmed.

Signs to watch for:

- High planner/scheduler turnover

- Complaints about schedule accuracy

- A noticeable shift from proactive planning to constant problem-solving

- General disengagement — planners just “going through the motions”.

The tools are supposed to make scheduling easier, not harder. If they’re doing the opposite, it’s time to ask whether the system is serving your people — or wearing them down.

Sign #5: Your schedule adherence is poor

When a plan is not executed properly (or on time), managers tend to first look at people. However, when it comes to maintenance scheduling, the problem might not be your team — it might be your tools.

When plans are constantly getting reshuffled, work orders go unexecuted, and schedule compliance starts to slip, it’s a clear sign something’s broken in the scheduling process.

What this looks like on the shop floor:

- Frequent work rescheduling

- Technicians showing up for work that’s already been moved

- Maintenance KPIs and metrics like unplanned downtime, standing work orders, and emergency work hours start trending in the wrong direction

- Operations starts losing trust in the maintenance schedule.

It’s a domino effect: poor tools → poor plans → poor execution.

And once schedule adherence drops, it’s tough to get control back — teams start ignoring the plan altogether, and maintenance becomes reactive instead of proactive.

Sign #6: You struggle to analyze or report on schedule performance

Every maintenance team should be able to easily track things like reschedules, reasons for delays, and adherence to the schedule.

If you are using SAP PM, you have probably encountered some of the following issues:

- There’s no built-in view of schedule adherence: You can see completed work, but tracking whether it happened as scheduled takes extra effort.

- It’s hard to see reschedules at a glance: SAP doesn’t surface how often jobs are moved or delayed — especially across multiple versions of a schedule.

- Root causes get lost: If work gets pushed out, there’s no easy way to log (or analyze) why — technician availability, material delays, etc.

- Reporting is manual and time-consuming. Pulling data means running reports, exporting tables, and stitching it all together in Excel.

- There’s no feedback loop. Without historical insights, planners can’t learn from past execution to improve future schedules.

- Data is unreliable: Because of extensive manual data management, reports are often inaccurate, making them unusable.

Without accurate (and timely) data, maintenance leaders are left with many blind spots that prevent improvements.

Introducing Sockeye: A purpose-built scheduling tool for SAP

Upgrading your scheduling process doesn’t require replacing SAP — it means extending it with tools that make scheduling actually work.

Sockeye is a simple maintenance scheduling tool built specifically for EAM and CMMS users. It bolts right onto your SAP system, giving planners and schedulers the modern features they need — without losing the connection to your core data.

What Sockeye brings to the table:

- Drag-and-drop (re)scheduling in a clean, user-friendly interface, backed by powerful automations.

- Two-way integration with SAP PM — one button to sync the data, no manual updates.

- Ability to quickly mark down reasons for delays (and spot merging trends).

- Automatic, visual reports that help you track pre-defined and custom KPIs.

Need more proof?Read how Sockeye filled in the gap in maintenance scheduling that was left after Cargil, one of the biggest companies in the U.S. agricultural industry, migrated to SAP.

Food for thought

Many companies struggle with outdated SAP PM scheduling workflows. However, they run large teams and are afraid of making significant changes. They hope things will improve with different workarounds, but they rarely do.

Modern tools like Sockeye help you move past these roadblocks — without ditching SAP. This makes the implementation and integration process extremely simple.

So take a closer look at your process. If it’s costing time, trust, or talent — it’s time for a change. Let’s jump on a quick call to see if Sockeye can help.