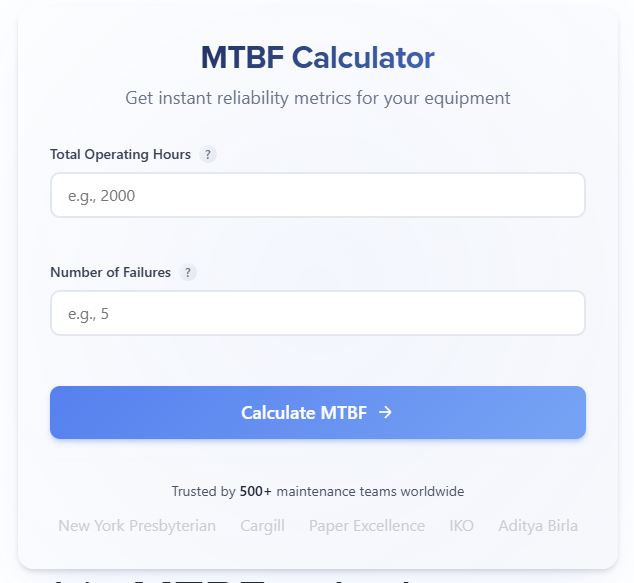

MTBF Calculator

Get instant reliability metrics for your equipment

Your MTBF

Get Your Educational MTBF Report

Learn how to apply your MTBF metric effectively

About this MTBF calculator

MTBF (Mean Time Between Failures) is one of the most common reliability metrics used to estimate how long equipment is expected to run before it fails. In other words, MTBF tells you the average operating time between breakdowns.

It can be calculated for one specific piece of equipment, as well as a group of assets.

The standard MTBF formula is simple:

MTBF = Total Operating Time ÷ Number of Failures

That’s the exact calculation our tool uses.

For example, imagine a pump that runs for 2,000 hours in total, and during that time it fails 4 times.

MTBF = 2,000 ÷ 4 = 500 hours

This means, on average, you can expect the pump to run about 500 hours before it fails again. Of course, this doesn’t guarantee the next failure will happen exactly at 500 hours — it’s just a statistical average that helps you plan maintenance better.

Other ways to calculate MTBF

The classic MTBF formula we showed is the most commonly used. But depending on your industry and the kind of data you collect, there are a couple of other ways to approach MTBF calculation:

- Failure rate method: Some reliability engineers use the inverse of the failure rate (λ) to calculate MTBF. For example, if your failure rate is 0.002 failures per hour, MTBF = 1 ÷ 0.002 = 500 hours. This approach is often used in engineering design and testing environments.

- Statistical distributions: In more advanced cases, MTBF can be estimated using probability distributions (like exponential or Weibull models). These methods are useful when you’re working with large data sets or when failures don’t follow a simple “average” pattern.

For day-to-day maintenance and reliability work, the standard formula is usually good enough. The key to accuracy isn’t so much about the method you use — it’s the quality (sample size + accuracy) of the data you plug in.

Getting the most accurate numbers to plug into the calculator

If you want MTBF results you can actually trust, here are some best practices:

- Record every unplanned failure. Only count breakdowns or unplanned stoppages. Ignore scheduled maintenance, inspections, or planned downtime.

- Track operating hours precisely. Use standardized timestamps (e.g., always log in hours, not sometimes in minutes and sometimes in days).

- Keep consistency across teams. Make sure everyone recording failures follows the same rules for what counts as a “failure” and how time is measured.

- Single asset vs. group of assets. You can calculate MTBF for one machine, or for a fleet of similar machines. Just be clear on what your scope is.

- Detailed logs. The more precise your failure logs are, the easier it is to spot trends and patterns later.

What does MTBF tell you about your equipment?

MTBF gives you a quick snapshot of how reliable an asset is:

- High MTBF: Equipment runs for long stretches without failure. That usually means it’s reliable, well-maintained, and operating within its design limits.

- Low MTBF: Frequent breakdowns. This could point to poor maintenance practices, aging equipment, or that the asset is being pushed harder than it was designed for.

Now, what counts as “good” MTBF depends a lot on the type of equipment:

- Electronics (like servers, routers): MTBF values are often in the tens of thousands of hours. For example, 50,000–100,000 hours is common in manufacturer specs.

- Industrial machinery: A few hundred to a few thousand hours is typical, depending on how tough the operating conditions are.

- Vehicles and mobile equipment: MTBF might be measured in mileage or hours of use, often landing in the hundreds to low thousands.

Industry benchmarks can be useful in certain scenarios. However, the real value is in tracking MTBF internally over time — to see the effects of your maintenance efforts and the impact of changing operating conditions.

What to do when you know MTBF?

Here are some smart ways maintenance and reliability managers can put it to work:

- Schedule preventive maintenance. If you know an asset’s MTBF is about 600 hours, you can schedule inspections or part replacements before the next likely failure point.

- Prioritize critical assets. Machines with lower MTBF values usually demand more attention. Allocate your maintenance budget and technician time where it will have the most impact.

- Improve resource planning. Knowing when equipment tends to fail helps you stock the right spare parts and reduce downtime.

- Support replacement decisions. If an asset’s MTBF keeps dropping despite regular maintenance, the data can help justify replacing it with a more reliable model.

Bottom line: MTBF isn’t just a number to look at once. Used smartly, it can guide maintenance schedules, reduce unexpected downtime, and even influence long-term investment decisions.