Maintenance workflows are rarely inefficient because your team doesn’t know what to do. More often than not, it’s because everyone’s doing the work differently. Without clear procedures, even simple tasks can lead to wasted time, rework, and safety risks.

That’s what maintenance SOPs (Standard Operating Procedures) try to solve. They provide a step-by-step guide that defines how to perform specific maintenance tasks in a safe, efficient, and consistent way.

By standardizing your maintenance procedures, you help improve equipment uptime, safety, and compliance with industry regulations.

In this guide, we cover:

- Which maintenance tasks deserve SOPs

- Which fields and information to include in a maintenance SOP

- What are the common SOP formats, and how to choose the right one for the task at hand.

At the end of the post, you’ll also find a handy maintenance SOP template you can use to plug your own procedures into.

Which maintenance procedures are worth standardizing?

Not every maintenance task needs an SOP. Some are too simple, rare, or low-risk to justify documenting. Focus on those that, if done incorrectly, have an impact on safety, machine uptime, or compliance.

Here are the types of tasks that maintenance teams like to standardize:

- Preventive maintenance routines — lubrication, inspections, filter replacements, belt tension checks, and similar.

- Safety-critical procedures — lockout/tagout, confined space entry, pressure system work, etc.

- Equipment changeovers or setups — especially when mistakes can cause downtime or damage.

- Calibration and testing — to ensure consistency and regulatory compliance.

- Emergency repairs and troubleshooting — to help techs respond safely and correctly under pressure to recurring equipment problems.

- Cleaning and sanitation — for tasks and assets where contamination or residue can cause issues.

When deciding which process to standardize, look at these factors:

- Frequency: Work performed often benefits most from consistency.

- Safety risk level: Any job with potential for injury or equipment damage should have a defined process.

- Complexity or potential for variation: If different people tend to perform it differently (i.e. using different tools or skipping steps), it needs an SOP.

- Regulatory requirements: Some industries require you to have written procedures for inspections or other work. Regulators can request to see those during compliance audits.

If a maintenance task checks even one or two of these boxes, take some time to write a standard operating procedure for it.

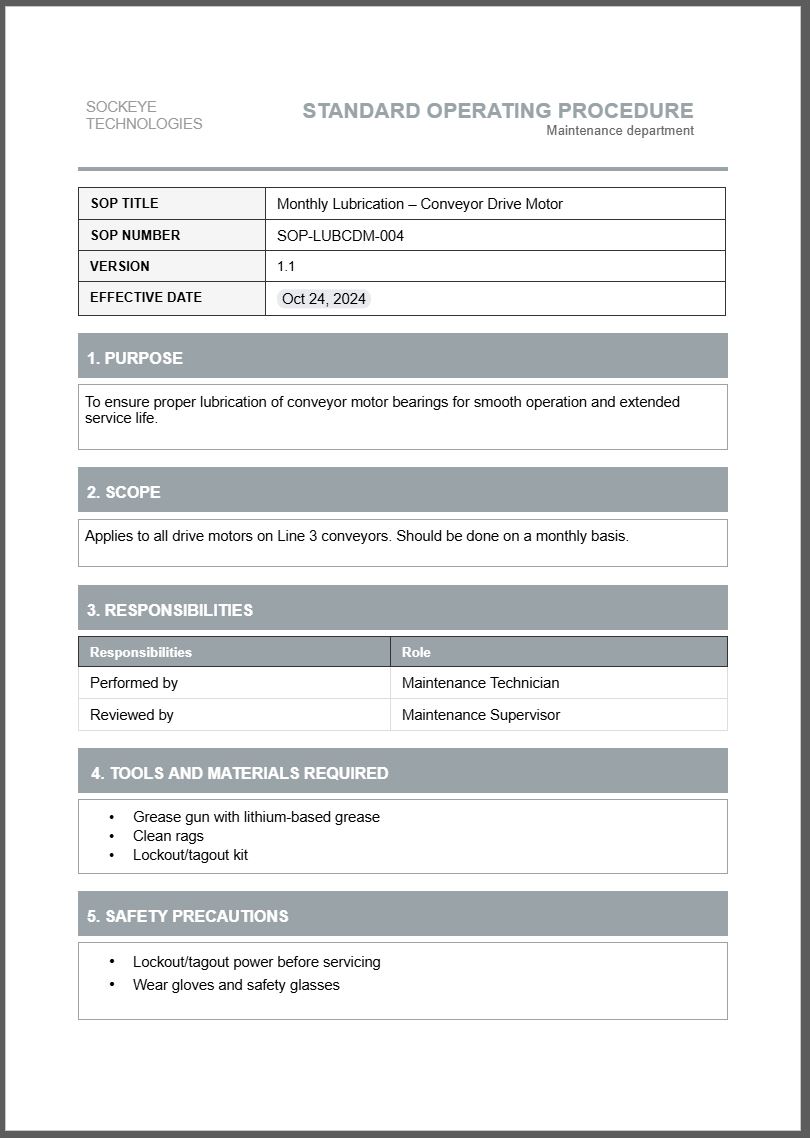

Things you should include in a maintenance SOP

A great maintenance SOP is simple to read and follow, and has just enough information that any qualified technician can complete the task correctly. Here’s what to include:

- Title and identification number: Give each SOP a clear title and a unique ID for tracking and version control.

- Purpose / Objective: Explain why this SOP exists — what it’s meant to achieve (e.g., ensure safe lubrication of pump bearings).

- Scope: Describe what the procedure covers — which equipment, system, or process it applies to.

- Responsibilities: Specify who performs the work. If applicable, also specify who supervises and approves it.

- Tools and materials needed: List everything required to complete the job safely and efficiently.

- Safety precautions: Note all PPE, lockout/tagout steps, and potential hazards.

- Step-by-step procedure: Lay out each step in order. Use numbered lists or checkboxes for clarity.

- Quality checks/acceptance criteria: For certain tasks, you’ll want to define what “good” looks like — how to confirm the job was done correctly.

- Documentation and recordkeeping: Explain how results or completion should be recorded (e.g., in your CMMS or maintenance logs).

- Revision history/approval signatures: Keep track of who created and who approved the SOP, along with dates and version numbers.

TIP: A picture is worth a thousand words. Sometimes, instead of long explanations, the smart move is to attach supporting materials like annotated photos, diagrams, or even short instructional videos.

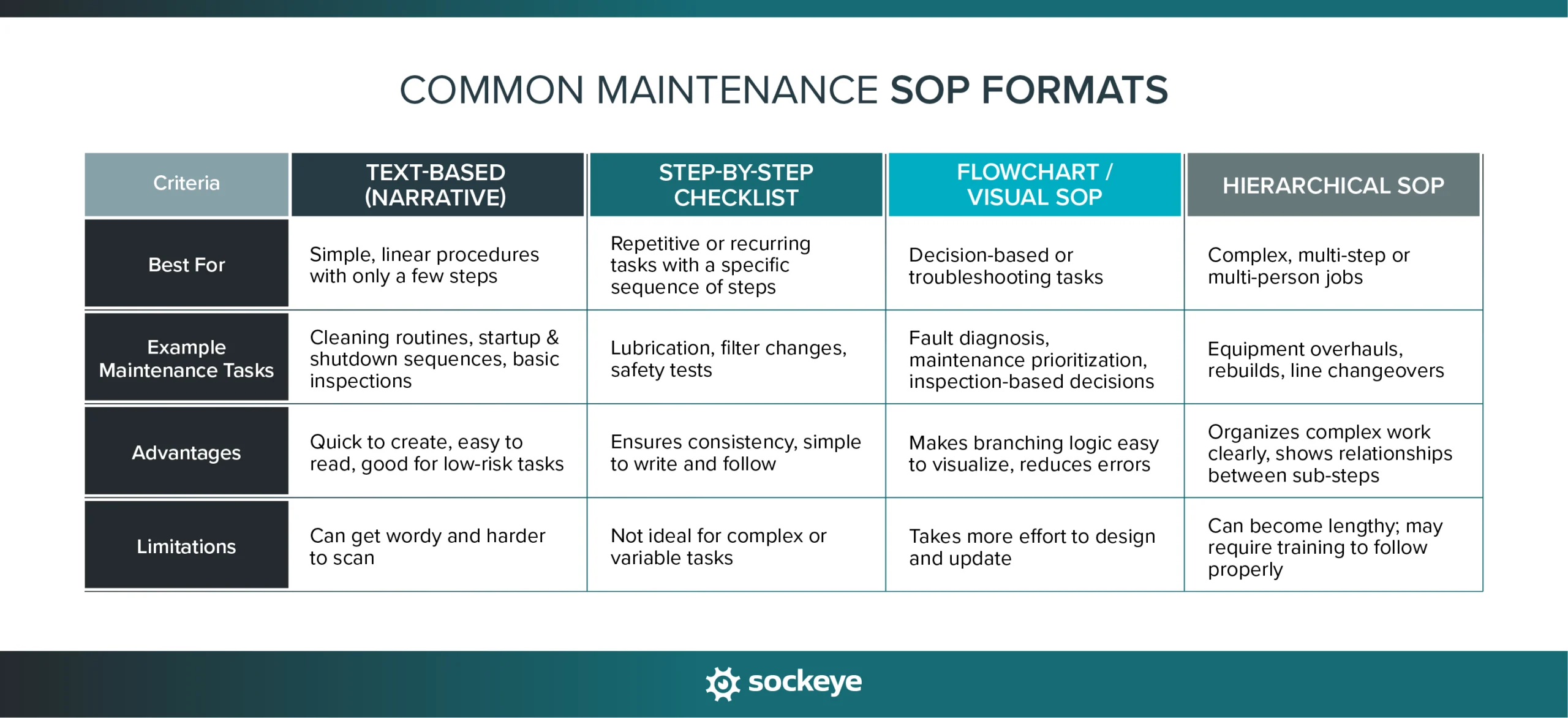

Maintenance SOPs can come in a few different formats

The most important part of any SOP is the included instructions. You can present them in a few different ways.

Choose one of the following formats based on the task’s nature, complexity, and how often the SOP will be used or updated.

TIP: For complex tasks, consider combining different formats into a single SOP.

Text-based (narrative)

Best for simple, linear procedures where each task flows naturally into the next. This format reads like a short instruction manual and is easy to write and understand.

Good for:

- Basic inspections (e.g., visual checks of safety guards or light fixtures).

- Cleaning routines for different assets and equipment.

Example: “To start up the air compressor, first verify that the main power switch is off. Inspect the oil level sight glass and top up if needed. Once confirmed, turn the power switch to ‘On’ and let the compressor run for two minutes before checking for abnormal noise or vibration.”

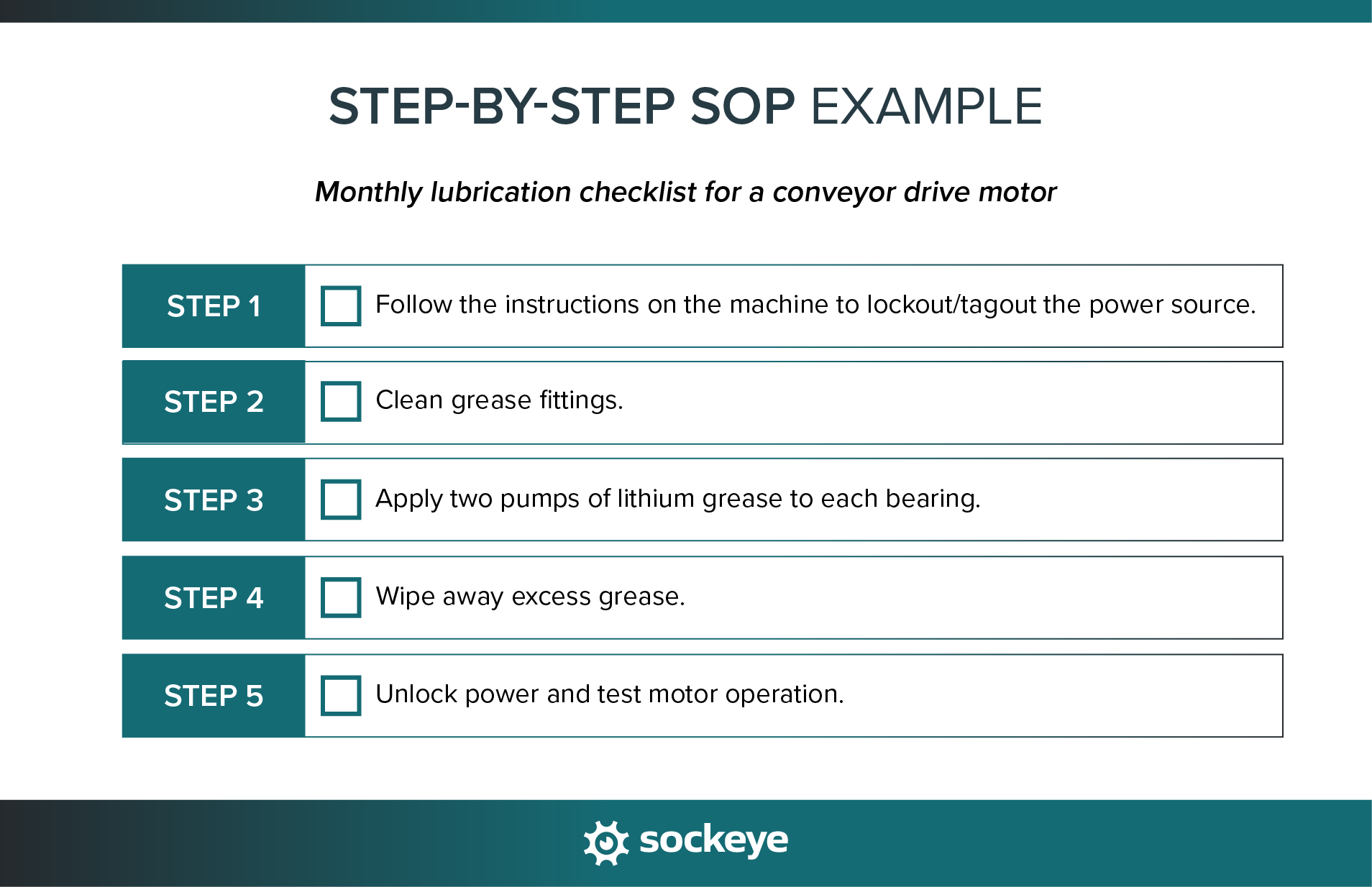

Step-by-step checklist

Perfect for repetitive or recurring maintenance tasks with multiple steps where consistency is crucial and you want to ensure every step is completed.

Good for:

- Lubrication routines

- Filter changes

- Belt and tension inspections

- Shutdown/startup sequences for production machines.

- Safety device testing.

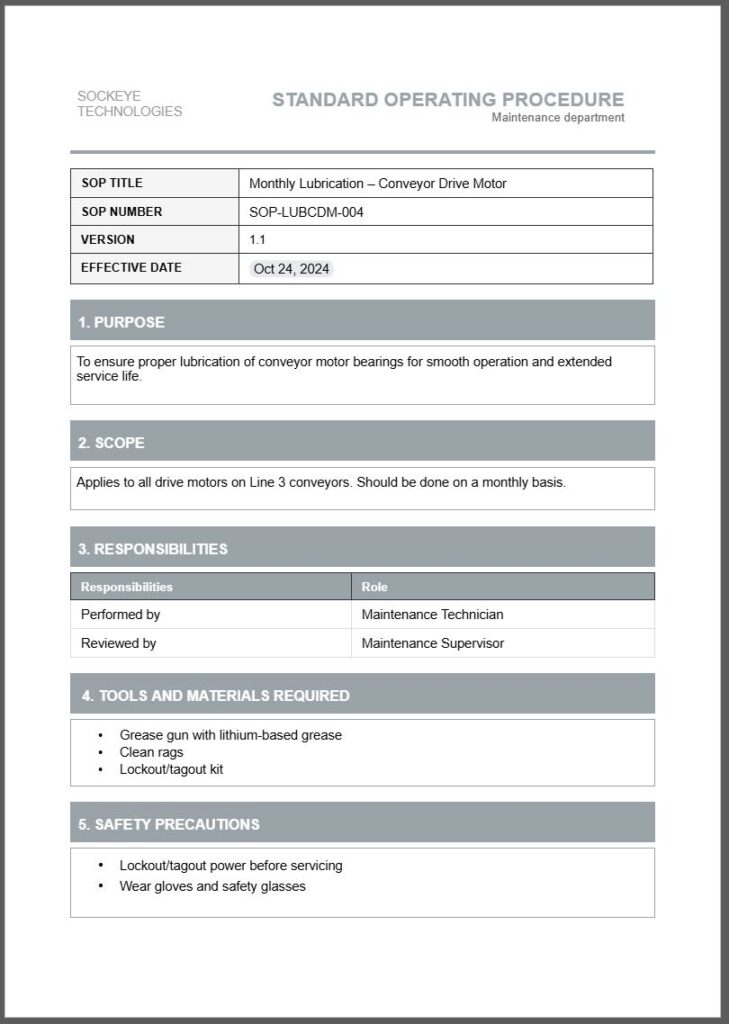

A simple step-by-step maintenance SOP would look something like this:

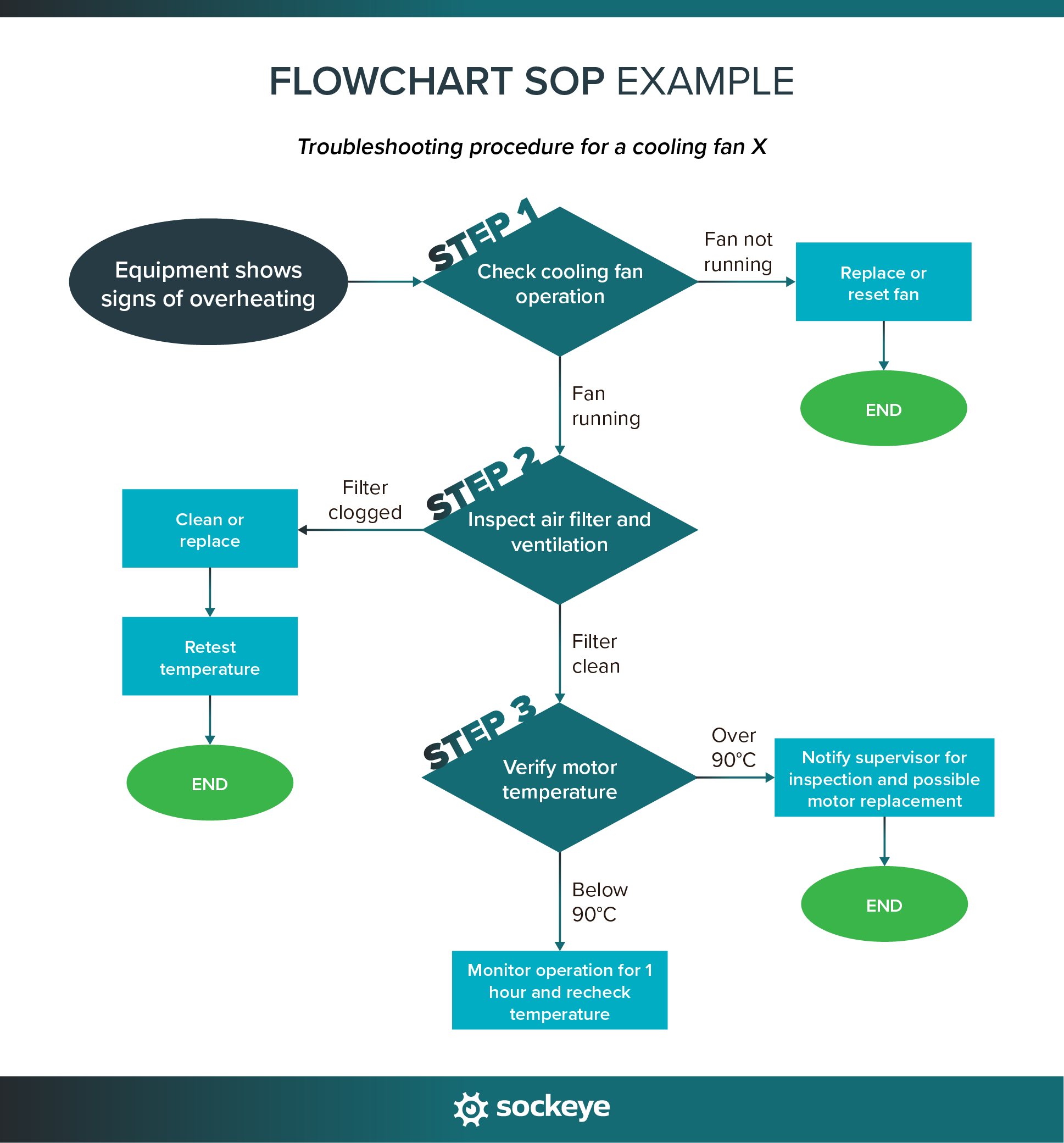

Flowchart (visual SOP)

A decision-based format ideal for processes that require branching logic — “If yes, do this; if no, do that.”

Good for:

- Troubleshooting electrical faults.

- Diagnosing temperature or pressure alarms.

- Work order prioritization and scheduling decisions (e.g., defer vs. perform now).

Here’s an example of a flowchart maintenance SOP:

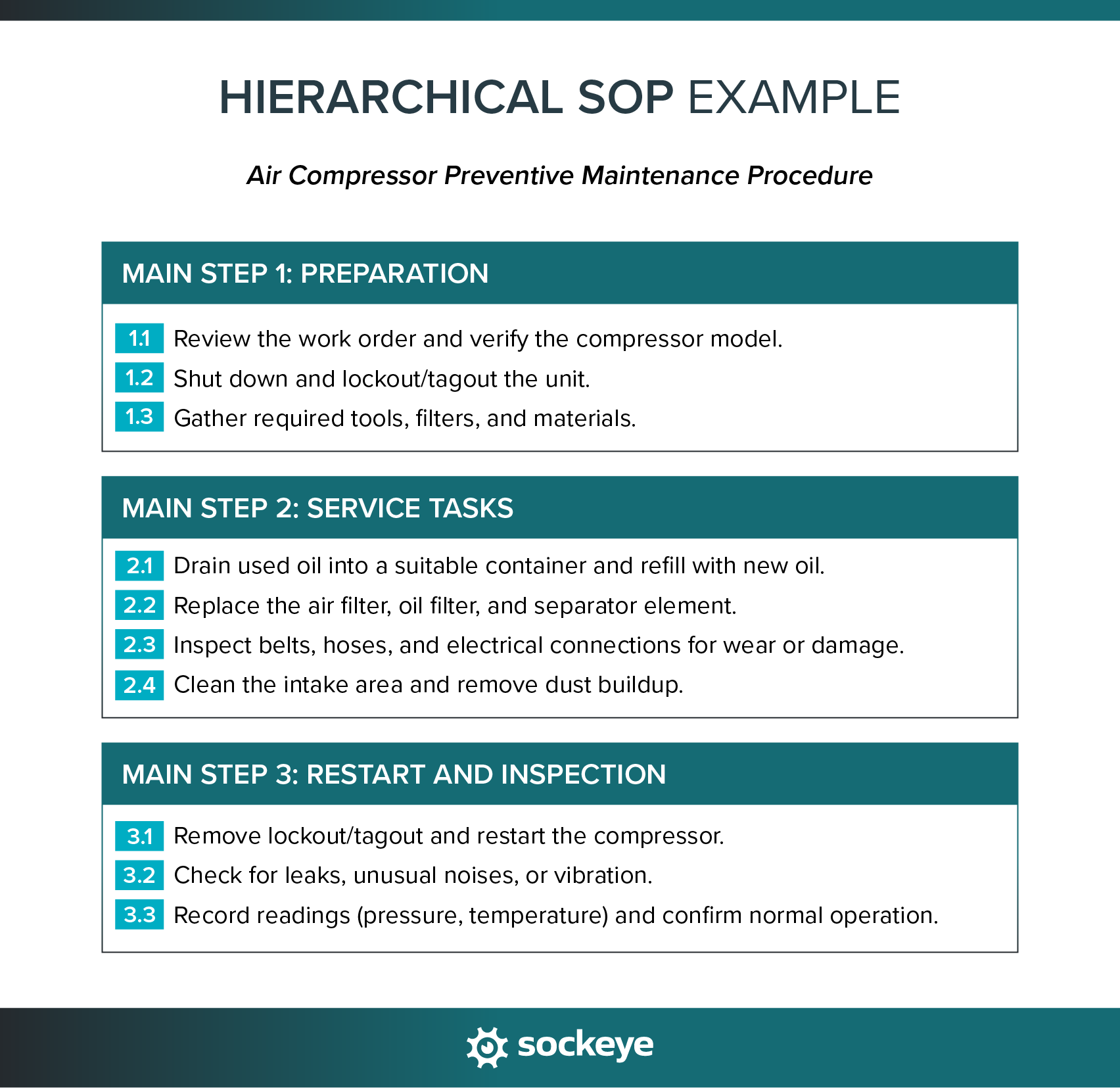

Hierarchical SOPs

Used for complex or multi-technician jobs where you need to break large tasks into main steps and detailed sub-steps. Keeps things organized without overwhelming the user.

Good for:

- Equipment overhauls or rebuilds.

- Line changeovers involving several systems.

- Complex PMs on large machinery (like turbines, presses, or packaging lines).

Below is an example of a hierarchical maintenance SOP:

TIP: Whenever possible, create your SOPs in a digital format. This way, you can attach them directly to work orders (WOs) or preventive maintenance (PMs). That makes them easy to access on the shop floor and ensures everyone’s using the latest version.

Maintenance SOP examples

To make this more concrete, let’s look at how a maintenance SOP might actually look in different formats.

Example #1: Step-by-step checklist — Machine lubrication SOP

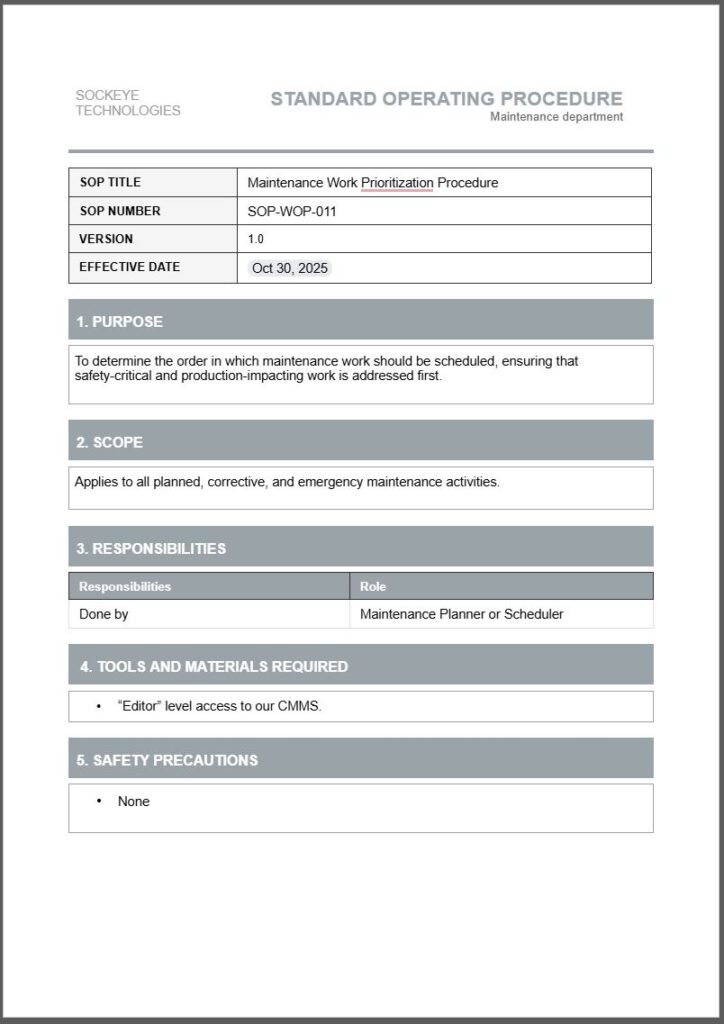

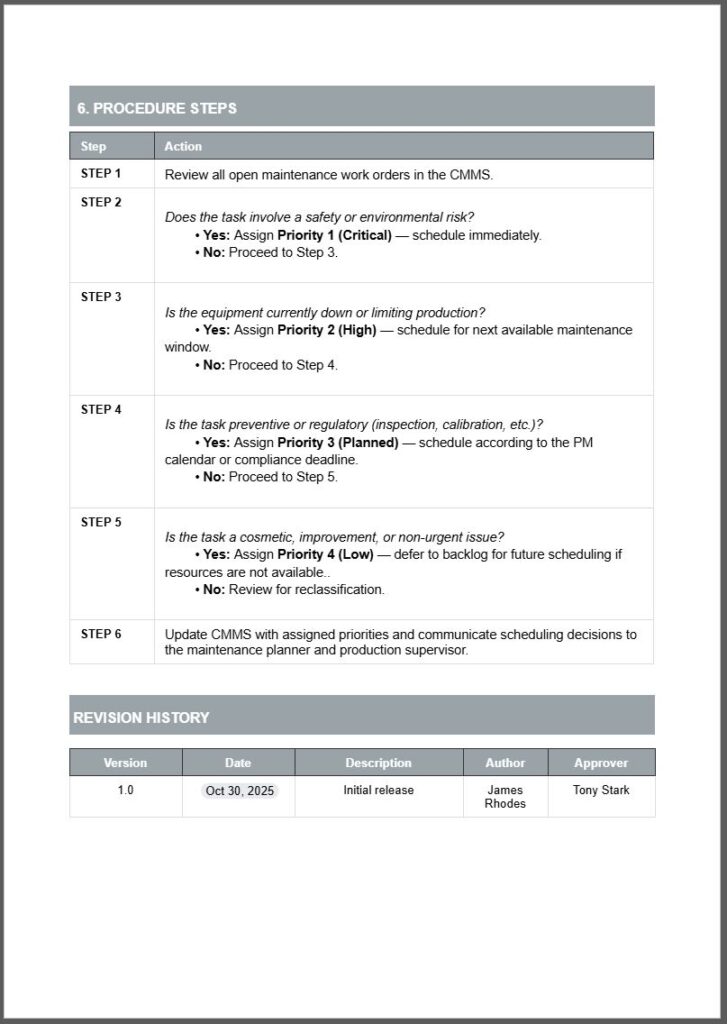

Example #2: Flowchart — Maintenance work prioritization SOP

Ideally, you would have an actual flowchart included in the “Procedure steps” section. However, you would need to do that in a separate tool and then insert it into your SOP document. To avoid that, the example below features a workaround.

Guidelines for writing standard operating procedures for maintenance operations

A good maintenance SOP strikes a balance — detailed enough that a responsible person can follow it, but not so long that no one actually does.

Here’s how to write SOPs that are clear, practical, and easy to use on the plant floor and in the field:

- Consult technicians: If you’re not the one who performs the task, talk to the people who do. They’ll spot missing steps or unrealistic instructions before the SOP is finalized.

- Define objectives and scope clearly: Do not forget to state what the SOP is meant to achieve and what equipment, system, or process it covers.

- Write in simple, action-oriented language: Use direct verbs like Inspect, Clean, Replace, or Verify. Avoid long explanations or vague phrases like “ensure proper operation.”

- Use consistent formatting and numbering: Numbered steps, clear headings, and bullet lists help technicians scan quickly and stay on track — especially when time-constrained.

- Add visuals where possible: Photos, diagrams, and flowcharts turn abstract instructions into something easy to follow. Use arrows, callouts, or labels to highlight critical details.

- Review and test with technicians: Have someone perform the task using the draft SOP and note any confusion or missing details. Then revise accordingly.

- Make the SOP easily accessible: Store all SOPs digitally in your CMMS or shared drive, and link them to related assets or PM tasks so technicians can open them directly from a work order.

Following these steps results in SOPs that are practical and useful, rather than mere paperwork that gets ignored.

Use our maintenance SOP template to quickly document procedures

Creating a maintenance SOP from scratch takes time, especially if you’re building several at once. To help you speed things up, we’ve put together a free maintenance SOP template.

The template includes all the key sections you’ve seen in this guide and examples — you can simply fill in the blanks.

Just duplicate the template, update the details for your specific task, and save it in your CMMS or shared maintenance folder. Before you know it, you’ll have a complete library of standardized maintenance procedures your whole team can rely on.

Make sure your SOPs do not go out of date

An SOP can do more harm than good if it is not current. Equipment changes, new safety standards come out, or you switch to different input materials — and suddenly your “standard” process isn’t so standard anymore.

Here’s how to keep them accurate and useful:

- Schedule periodic reviews: Go through each SOP at least once a year (or sooner if equipment or processes change).

- Track revisions: Utilise a revision history table to ensure everyone is aware of the current version.

- Get technician feedback: Encourage techs to flag unclear steps, edge cases that aren’t covered, or inconsistencies they notice on the job.

- Monitor for regulatory or process changes: Update SOPs when new safety rules, materials, or tools are introduced.

So don’t wait — grab our free maintenance SOP template, start documenting your key processes, and use standardization to boost maintenance productivity.