High machine downtime = missed production targets, frustrated teams, and money lost.

High machine uptime = high productivity; predictable, safe, and cost-efficient operations.

This article explains what uptime really tells you, how to calculate it, and the proven strategies that help maintenance teams maintain high equipment uptime.

What does machine uptime mean?

Machine uptime, which is sometimes referred to as run time, is the amount of time equipment is up and running as expected. It is tracked as a percentage and gives you a quick read on how reliable your assets really are.

- High uptime means machines are dependable, well-maintained, and able to deliver steady output.

- Low machine uptime signals frequent breakdowns, long waits for parts or technicians, or poor maintenance practices.

Sidenote: Uptime is often confused with availability. What is the difference? Uptime measures how long equipment is running, while availability measures how often it’s ready to run when it’s actually needed.

Machine uptime calculation

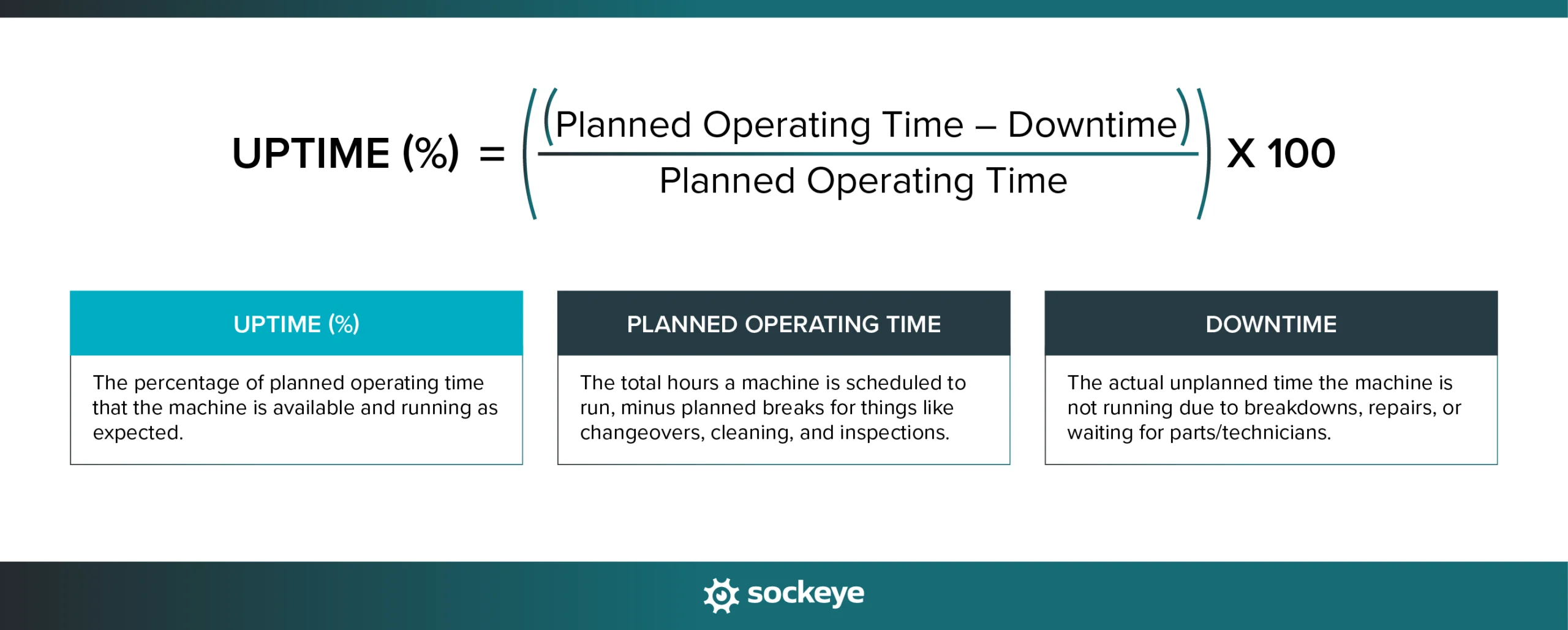

The basic formula for uptime is:

Uptime (%) = ((Planned Operating Time – Downtime) ÷ Planned Operating Time) × 100

Example: A machine is scheduled to run for 720 hours in a month. Built into that schedule are 40 hours of planned breaks for routine maintenance and changeovers. Out of the remaining 680 planned production hours, the machine is down for 20 hours due to a couple of unexpected breakdowns.

- Planned Operating Time = 680 hours

- Downtime = 20 hours

- Uptime = ((680 – 20) ÷ 680) × 100 = 97.1% uptime

By excluding scheduled maintenance, you get a more accurate picture of machine reliability and avoid artificially lowering uptime with downtime that was actually intentional.

Tracking this number month over month helps you spot patterns — are failures becoming less frequent with more preventive maintenance, or more frequent as equipment ages?

The relationship between equipment uptime and maintenance planning and scheduling

Uptime and maintenance planning go hand in hand. Poor and inconsistent planning leads to constant firefighting. Emergency fixes often take longer because parts aren’t on hand, technicians have to be pulled away from other jobs, and repairs happen under pressure.

A regular preventive maintenance schedule helps maintain higher machine uptime by reducing the number of unexpected failures.

Strong planning and scheduling also mean you can slot maintenance into natural pauses in production, like shift changes or planned breaks. That minimizes disruption without sacrificing maintenance quality.

Strategies to increase machine uptime

Many things influence whether machines stay running or break down — maintenance strategy, operator habits, spare parts availability, and even how work orders are documented. The challenge for maintenance leaders is knowing where to focus first.

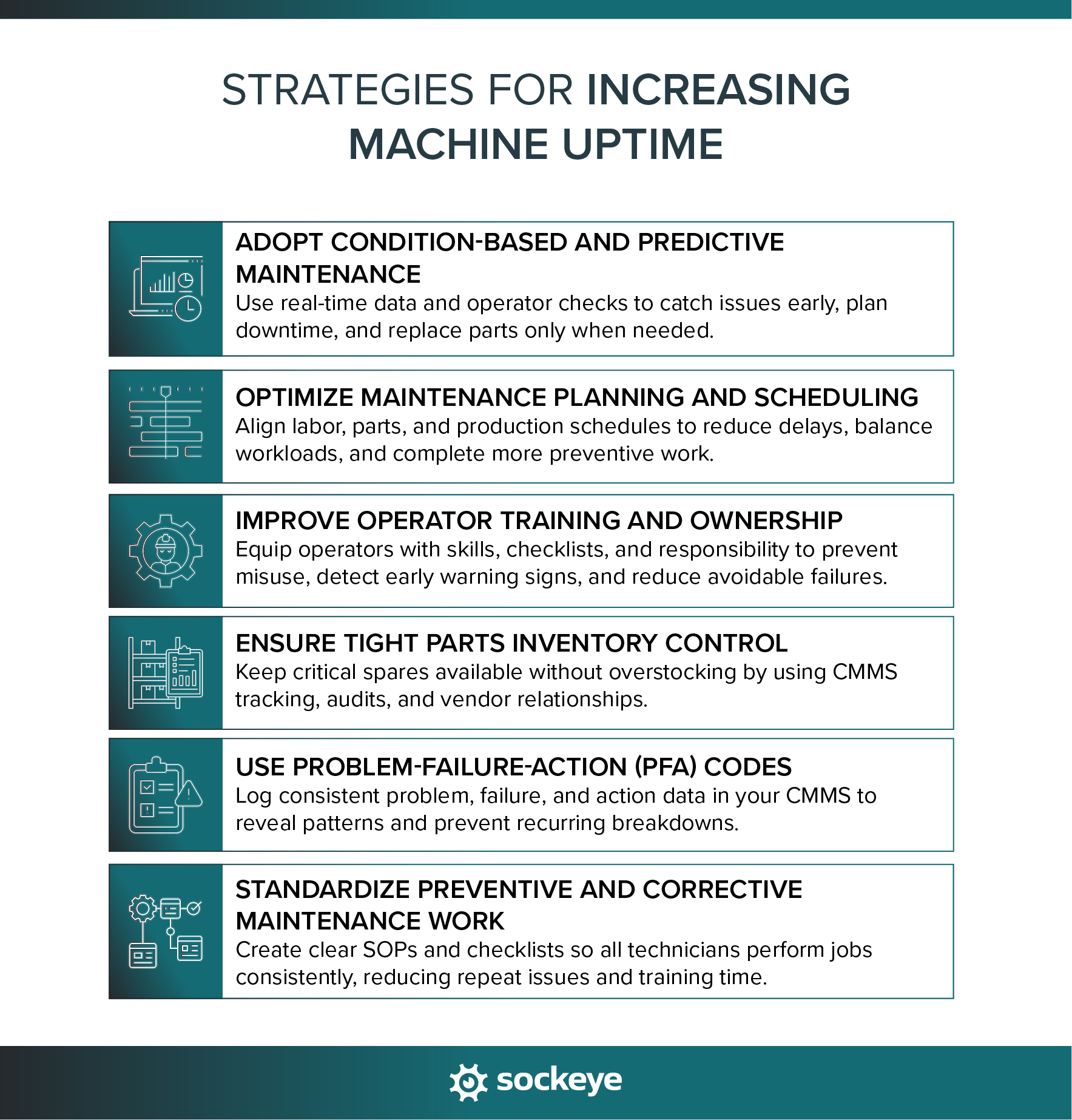

Below are six effective strategies to boost equipment uptime. We focused on those that can be applied to any production floor without overcomplicating day-to-day operations.

1) Adopt condition-based and predictive maintenance

Traditional preventive maintenance is done on a usage, fixed, or floating schedule — whether it’s needed or not. Condition-based and predictive maintenance take it further by using real-time data (such as vibration, temperature, or oil analysis) to trigger maintenance only when the machine exhibits signs of wear.

Why it matters for uptime: Problems are caught earlier, downtime is planned instead of sudden, and parts last longer since they’re replaced only when necessary.

How to apply it on a busy production floor:

- Start small by monitoring critical assets with low-cost sensors and condition monitoring techniques.

- Use simple condition checks operators can do during daily inspections (noise, leaks, vibrations). You can also build these condition checks into existing PMs.

- Feed and log sensor data into your CMMS and send automatic alerts when thresholds are crossed (i.e. temperature crosses X degrees).

This shift to more predictive maintenance is often the biggest step toward higher uptime.

2) Optimize maintenance planning and scheduling

Planning and scheduling are at the center of every maintenance strategy. Without good processes to plan and schedule work, everything falls apart.

Why it matters for uptime: When maintenance is poorly planned, repairs take longer and decrease uptime. Similarly, inefficient scheduling leads to less preventive work being done or PMs being delayed, resulting in more equipment downtime in the long run.

Actionable tips:

- Use real-time labor availability to schedule work near 100% capacity without going into overtime. Use the same data to balance workloads evenly between teams.

- Use a maintenance scheduling app like Sockeye to digitize and simplify your scheduling process. You will also be able to track reasons why any PMs and WOs get delayed.

- Line up spare parts and tools before scheduling work orders to avoid mid-job delays.

- Use planned production breaks, shift changes, or weekends as natural slots for preventive work.

- Review the schedule daily and adjust priorities as conditions change, but stick to the weekly plan as much as possible.

3) Improve operator training and their sense of ownership

Operators are the first line of defense for keeping machines running smoothly — but they can also be a hidden cause of downtime. Incorrect machine use, skipped inspections, or rushed changeovers often lead to failures that could have been avoided.

Why it matters for uptime: Better training and a stronger sense of ownership turn operators from a common source of problems into a powerful uptime booster. When operators understand how their actions affect reliability, they’re more likely to run equipment correctly, report early warning signs, and treat machines as assets they’re responsible for — not just tools they use.

Actionable tips:

- Provide short, focused training on both correct operating procedures, failure indicators, and the most common mistakes that cause failures.

- Build daily inspection and cleaning checklists into operator routines to catch small issues before they grow. Often done as a part of autonomous maintenance.

- Encourage operators to report issues instead of waiting for something to break.

- Recognize and reward operators who prevent downtime by catching problems early.

4) Ensure tight parts inventory control

Think of your parts storeroom as an insurance policy for uptime. The right part, in the right place, at the right time, can be the difference between a 30-minute fix and a 3-day shutdown.

Why it matters for uptime: If critical spares are missing, breakdowns stretch from hours into days. On the flip side, keeping every part in stock ties up cash and clutters storage. Maintaining the right stock levels is easier said than done, especially if you do more reactive than preventive maintenance.

Actionable tips:

- Classify parts by criticality: stock critical spares locally, and order less critical ones as needed.

- Develop relationships with multiple vendors, so you have more options when making emergency orders.

- Be careful when not using OEM parts. Cheaper solutions usually mean lower quality, needing more frequent replacements.

- Use your CMMS or ERP to track usage history and set reorder points. Get notified when any part is “low in stock”.

- Occasionally, audit storerooms to prevent “phantom inventory” (when parts are listed as in stock but nowhere to be found).

- Standardize parts across similar machines when possible — fewer part types means fewer headaches.

5) Use Problem-Failure-Action (PFA) codes

When a machine goes down, it’s not enough to just get it running again. To truly boost uptime, you need to understand why it failed and what action resolved the issue.

That’s where Problem-Failure-Action (PFA) codes come in:

- Problem = the symptom (e.g., “machine won’t start”).

- Failure = the root cause (e.g., “blown fuse”).

- Action = what was done to fix it (e.g., “replaced fuse”).

Why it matters for uptime: By logging PFA codes in your CMMS, you can spot patterns across machines. Maybe one line has the same recurring electrical issue, or a certain pump always fails the same way after 2,000 hours. This data lets you move from “firefighting” to preventing those failures — or at least being prepared for them.

Actionable tips:

- Start small by applying PFA codes to the most critical assets first.

- Train technicians to enter codes consistently so the data is usable.

- Review coded failures monthly to identify repeat offenders and prioritize fixes.

Over time, PFA codes turn maintenance data into a map of where downtime originates — and how to eliminate it.

💡 Tip: Sockeye’s users can also leverage our built-in delay codes and BI integration to take this insight further. Delay codes help teams categorize exactly why maintenance or production stalls — whether it’s waiting on parts, tools, or approvals. BI dashboards then visualize those patterns, helping supervisors drill down to specific problem areas, coach the whole maintenance team to speed up MTTR (Mean Time To Repair), and target corrective actions that directly improve uptime.

6) Standardize both preventive and corrective maintenance work

When every technician has their own way of doing the same job, the results are unpredictable. One person might replace a bearing correctly, while another leaves out lubrication or skips alignment. Standardizing both preventive and corrective work ensures jobs are done right, every time.

Why it matters for uptime: Consistent execution reduces repeat failures and cuts down on avoidable downtime. It also enables faster training of new technicians and helps capture knowledge from experienced staff before they leave or retire.

Actionable tips:

- Create clear job plans or checklists for common tasks like lubrication, belt changes, or bearing replacements.

- Store procedures in your CMMS so technicians always have the latest version at hand. Digital SOPs and checklists are way easier to manage and keep up-to-date.

- Use feedback from the floor to keep instructions practical — technicians won’t follow checklists that don’t reflect real-world conditions.

- Audit completed work periodically to confirm standards are being followed.

Standardization removes guesswork, speeds up maintenance, and keeps uptime from depending on “who’s on shift today.”

Smart machine uptime management pays off

Machine uptime is the result of consistent practices. It is measurable, improvable, and closely tied to how well maintenance is planned, scheduled, and executed.

Investing in better scheduling, operator training, spare parts control, and more predictable maintenance strategies pays off in fewer breakdowns, steadier production, and safer operations.

Tools like Sockeye make it easier to put structure around scheduling, so teams spend less time reacting and more time keeping machines healthy and running.

By focusing on uptime, you’ll see the payoff in productivity, cost control, and peace of mind across the plant.