When people discuss asset reliability, the conversation often focuses on data, design, or failure analysis. But there’s one area that doesn’t get nearly enough attention: scheduling.

Reliability is still the gold standard in operations — it’s what keeps plants running, people safe, and budgets intact. Yet, many organizations treat maintenance scheduling as a basic administrative task rather than the strategic tool it really is.

In this article, we’ll break down how maintenance and reliability connect, how smart scheduling impacts equipment reliability, and where most teams go wrong. If your reliability numbers aren’t where you want them to be, your schedule might be the first place to look.

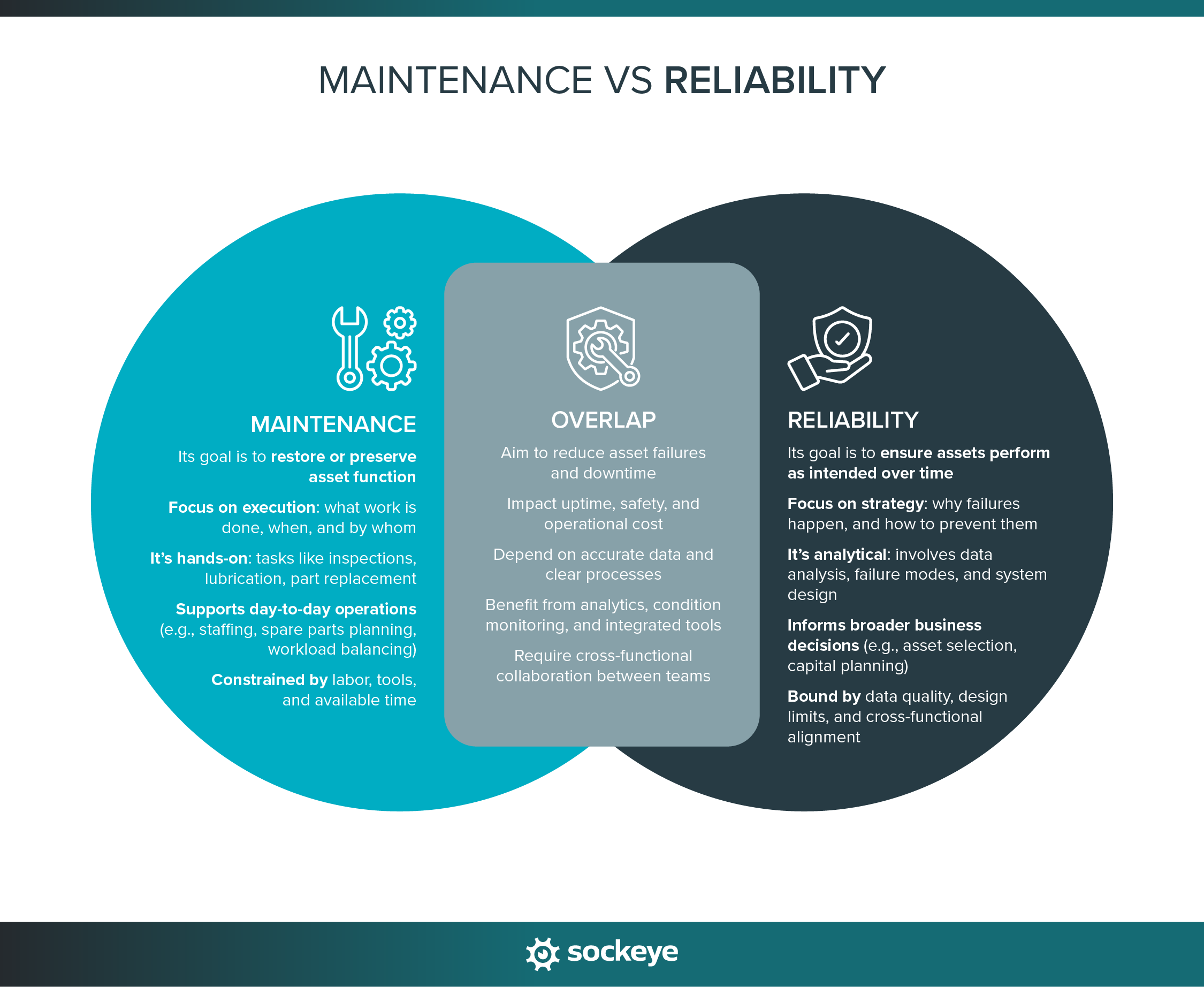

Quick definitions: Maintenance vs. Reliability

Before we dive deeper, let’s get clear on what we mean by maintenance and reliability. They’re closely connected but not the same thing — and confusing them can lead to poor decisions:

- What is Maintenance? Maintenance is a coordinated set of actions taken to preserve or restore an asset’s function. This includes both proactive and corrective maintenance work.

- What is Reliability? Reliability is the probability that an asset will perform its intended function without failure for a specified amount of time, under stated conditions.

You can think of it as: maintenance is what you do; reliability is the result you’re aiming for.

Where do reliability and maintenance overlap?

Maintenance and reliability share many of the same goals:

- Both aim to reduce failures: At their core, both functions are working to keep assets running as intended. Maintenance does this by taking action; reliability does it by understanding and preventing failure modes.

- Both need cross-functional collaboration: Technicians, planners, engineers, and operators all have a role to play. When these groups work in silos, things fall through the cracks — schedules slip, data gets ignored, and failures creep in.

- Both influence uptime, cost, and safety: Poor maintenance impacts reliability, and poor reliability increases the burden on maintenance. Either way, the result is more downtime, higher costs, and increased safety risks.

- Both benefit from technology and analytics: From condition monitoring tools to CMMS platforms, both disciplines rely on good data to make smart decisions. The more integrated the systems, the better the outcomes.

When done right, reliability and maintenance support each other in big ways.

The difference between maintenance and reliability

You maintain assets to achieve reliability. But here’s the catch: you can’t maintain your way to unlimited reliability.

Imagine this: you’ve got a pump that isn’t meeting performance expectations. You increase the frequency of preventive maintenance — tighten schedules, add inspections, maybe even swap parts early. At first, you might see improvements. But eventually, no matter how much maintenance you throw at it, reliability plateaus.

That’s because reliability has design limits. If an asset wasn’t built to handle your operating conditions, better maintenance alone won’t fix it. At that point, you’re in the territory of reliability engineering — redesigning, modifying, or re-specifying the equipment.

This is why understanding the difference between the two matters.

If you treat every reliability issue as a maintenance problem, you’ll waste time, burn resources, and still fall short of performance goals.

But the reverse is also true. Not every failure points to a reliability problem. Sometimes it’s just poor maintenance execution — a missed task, a late PM, or the wrong part. That’s not a design flaw; it’s a planning or scheduling issue.

And that’s why reliability and maintenance teams need to stay in constant dialogue.

How maintenance scheduling impacts reliability

Maintenance scheduling is more than just organizing calendars — it directly impacts whether assets perform as expected or fail prematurely.

Here’s how:

- Timely scheduling prevents both over-maintenance and under-maintenance. Too much maintenance wastes time and money. Too little leads to failures. A smart PM schedule will try to hit the sweet spot.

- Good scheduling aligns maintenance effort with asset criticality. Not all assets are equal. Your schedule should reflect which ones have the biggest impact on production, safety, or cost when they fail.

- Structured, consistent schedules reduce reactive work. The better you plan, the more efficient your team can be. Keeping up with your weekly PMs will go a long way in reducing the number of asset breakdowns.

- Efficient schedules improve labor and resource utilization. When you’re not double-booking crews or waiting on parts, your people get more work done — and assets stay healthier as a result.

Here’s a quick example:

In a food processing plant, a key conveyor motor started failing every 6–8 weeks despite regular maintenance. After reviewing the schedule, the team realized maintenance was being logged but not executed on time due to crew overload. They adjusted the schedule to align tasks with available labor and prioritized the motor’s preventive maintenance.

The failures stopped. Reliability improved — not because of more maintenance, but because of better-timed maintenance.

Common scheduling pitfalls that harm reliability

Even with the best intentions, poor scheduling practices can quietly chip away at reliability. Below are some of the most common pitfalls — and how to avoid them:

- Not linking scheduling to asset criticality. Treating all assets equally leads to wasted effort. Tip: Prioritize scheduling around equipment that poses the highest risk to safety, production, or cost.

- Lack of schedule discipline. A schedule is only useful if people actually follow it. Tip: Track maintenance schedule compliance and hold teams accountable for sticking to the plan.

- Poor follow-through on scheduled tasks. It’s scheduled, but was it completed? Was it done right? Tip: Use your work order scheduling software to log completions and feedback — don’t assume a scheduled task is a completed task.

- Using rigid time-based intervals instead of asset data. Doing work “because it’s time” can lead to excessive maintenance. Tip: Where possible, use condition monitoring or runtime data to plan maintenance work.

- Poor communication between planners, schedulers, and technicians. Misalignment leads to missed work, duplicate efforts, or confusion. Tip: Establish a regular handoff process and daily/weekly coordination between these teams.

- No feedback loop to the reliability team. If failures keep happening, but that info never gets to the reliability group, nothing improves. Tip: Build a feedback loop — technicians should report what they see in the field, and planners/schedulers should actively track the reasons for any scheduled task being delayed.

The role of maintenance scheduling tools in improving equipment reliability

Modern maintenance scheduling tools — usually built into a CMMS or EAM — do a lot more than just organize work orders. When used well, they become strategic enablers of reliability.

The challenge? Many of these tools are overly complex. The interface might be clunky, the logic hard to follow, or the workflows not suited for fast-moving operations. As a result, planners and schedulers often fall back on spreadsheets or gut-feel decisions — and reliability suffers.

That’s where tools like Sockeye come in. Sockeye is designed to integrate with your existing CMMS or EAM, making scheduling simpler. It removes the technical barriers and helps teams build and stick to realistic, efficient schedules.

A good scheduling tool enables you to:

- Easily balance workloads across crews

- Plan around real labor availability

- Avoid overtime and burnout while scheduling more work

- Leverage automation to quickly schedule and reschedule work without messing up future schedules.

And all of that directly improves reliability — because more work gets done on time, by the right people, with less chaos.

Final thoughts

Reliability doesn’t just come from good intentions or better equipment — it comes from the day-to-day discipline of doing the proper maintenance at the correct time. And that starts with scheduling.

If your reliability numbers aren’t where they should be, take a hard look at your schedule. Is it realistic? Prioritized? Actually being followed? If not, no amount of maintenance will get you where you want to go.

Smart scheduling is one of the most overlooked — and most powerful — levers for improving reliability. Use it well.