Most plants underestimate the true cost of poor planning and chaotic scheduling. Lost wrench time, surprise downtime, and constant firefighting can quietly drain millions in productivity every year.

In contrast, when planning and scheduling are done well, everything changes — uptime increases, crews work more efficiently, and maintenance becomes less reactive and more predictable.

This guide will explain how to build a reliable work-order planning and scheduling discipline that you need to enjoy all those benefits.

Laying the foundation with clear roles and responsibilities

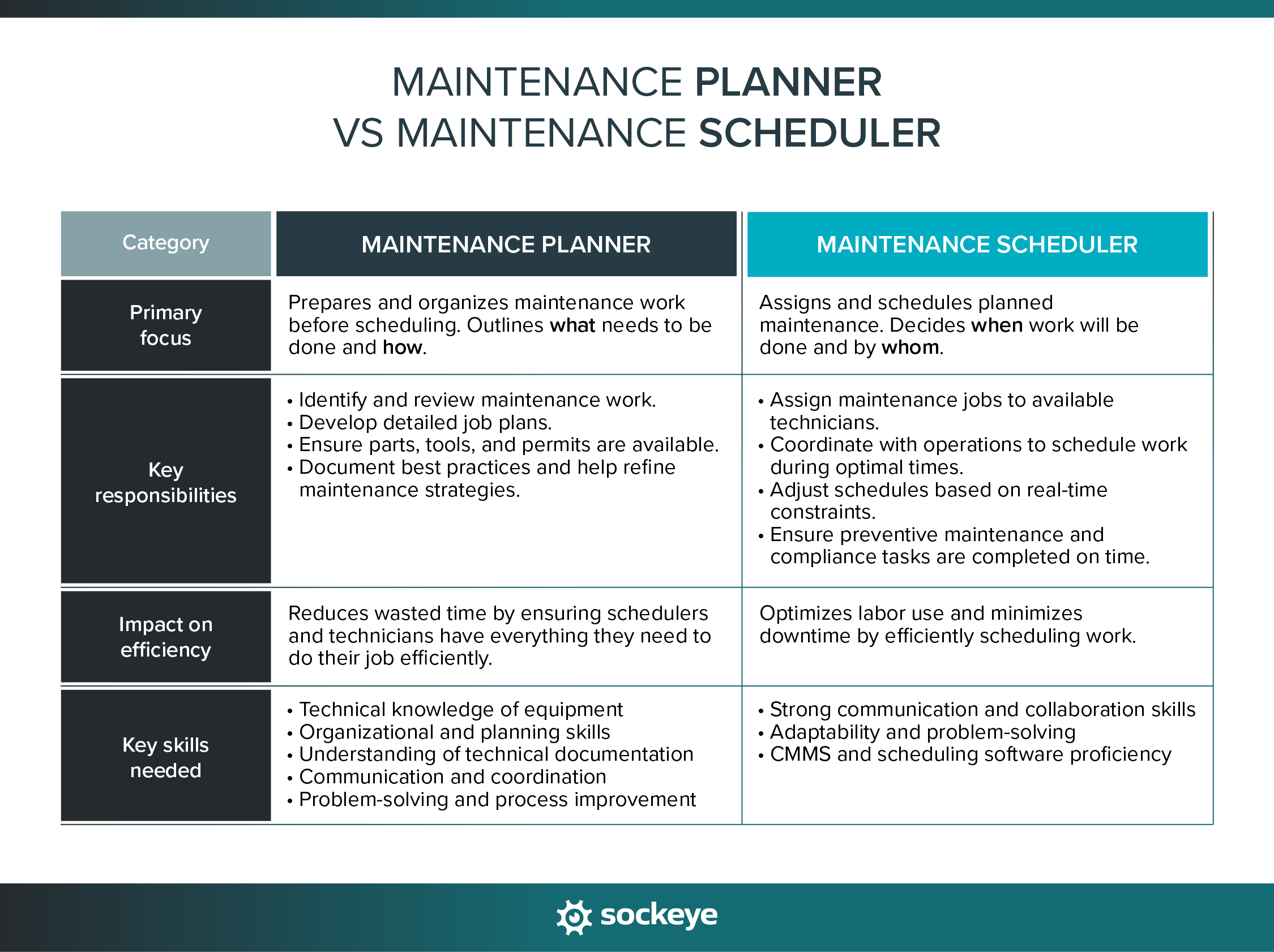

Many plants blend planning and scheduling into one overworked role. But the two functions are quite different:

- Planning makes the work executable — defining the scope, parts, permits, and steps.

- Scheduling decides when the work will be done and who will do it based on labor availability and production opportunities.

When these responsibilities are mixed, you end up with missed commitments and poorly planned jobs because the planner/scheduler has to spend most of their time scheduling work (cross-referencing multiple spreadsheets or navigating complex, clunky scheduling interfaces).

Clear role boundaries help set the foundation for a more controlled process.

Who does what in the WO planning and scheduling process?

Each role plays a specific part in the workflow:

- Planner: Prepares work for efficient execution — job scoping, parts and materials, permits, and accurate estimates.

- Scheduler: Matches planned, “ready-to-schedule” work orders to available labor and production windows.

- Technician: Performs the work and provides post-job notes so plans improve over time.

- Supervisor: Oversees the progress, manages day-to-day adjustments, and ensures accurate feedback after jobs.

The exact responsibilities will vary based on team size and composition, but this is what you should broadly aim for.

Why role clarity is critical

When roles blur, chaos creeps in. Planners end up chasing parts or reacting to breakdowns. Schedulers create schedules around half-complete work orders. Supervisors bypass the system because they don’t trust what’s in it.

Separating the planning and scheduling role prevents this. Each person has a clear focus, specific KPIs, and the ability to build discipline into the process. A simple RACI-style breakdown looks like this:

- Planner: Responsible for making the job executable.

- Scheduler: Accountable for building a realistic weekly schedule.

- Supervisor: Responsible for executing the schedule and entering feedback.

- Technician: Consulted during planning, executes jobs according to instructions, and provides feedback.

- Operations & Production: Informed and aligned on priorities and downtime windows.

Tools that support role separation

Your CMMS/EAM stores the planning data — job steps, materials, estimates, etc. However, it often isn’t designed for fast, visual scheduling.

That’s where a work order scheduling bolt-on like Sockeye comes in. They give schedulers instant visibility into workload and capacity, making it easier to build realistic schedules. Schedulers get a dedicated tool, and the data is constantly synced with your CMMS through read/write integration.

It’s a perfect way to separate planning and scheduling, but still keep everyone connected and up-to-date on what is scheduled, in progress, delayed, and done.

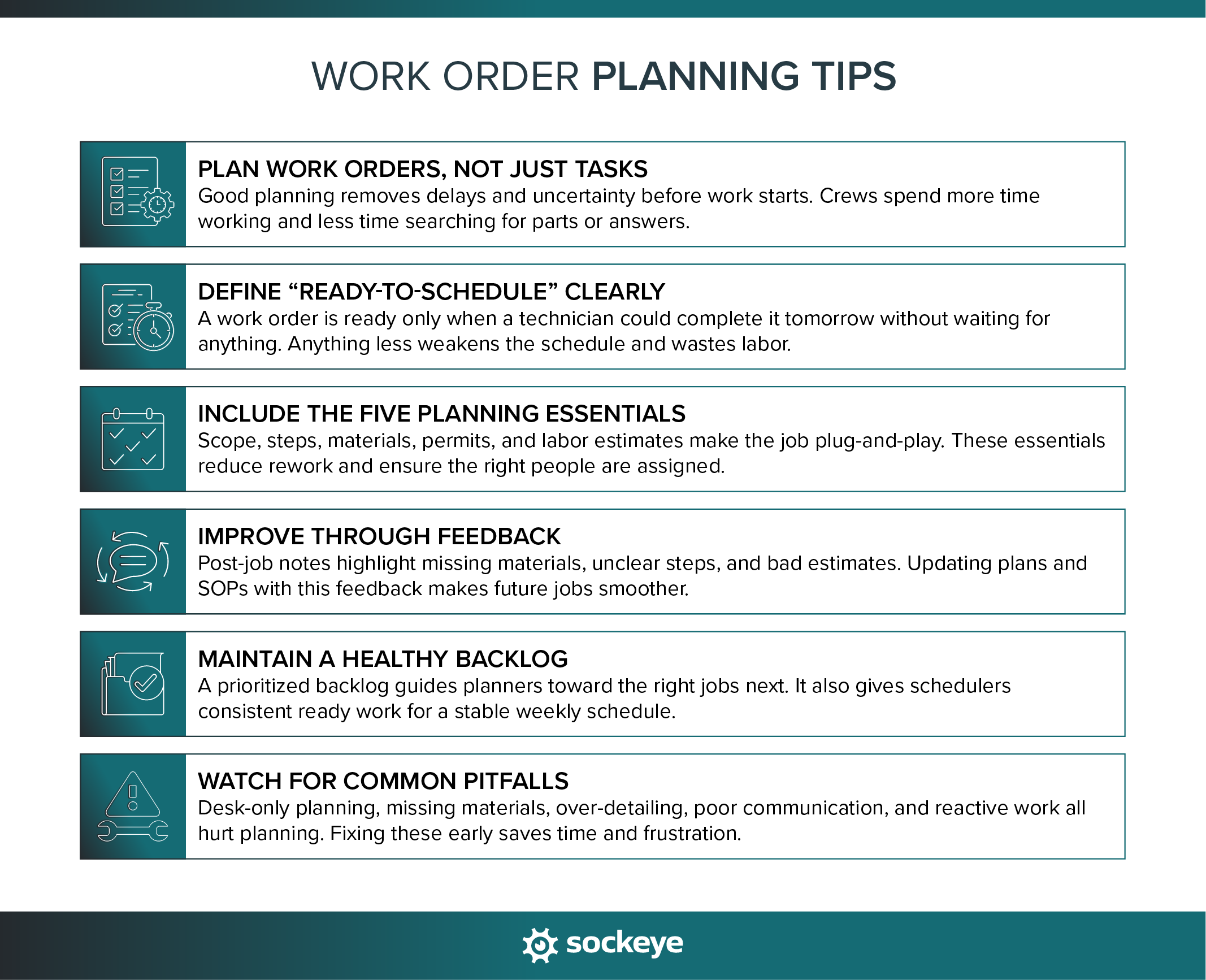

Work order planning done right

Strong planning is the engine behind reliable maintenance. It makes everything move faster. Crews spend more time turning wrenches and less time tracking down parts, waiting on permits, or redoing unclear work.

What “ready-to-schedule” really means

A work order isn’t “ready-to-schedule” just because it exists in the CMMS. It’s ready only when a technician can walk out tomorrow and execute it without delays or guesswork. That means:

- The scope is defined — what’s being done and what “done” looks like.

- Materials and parts are identified, procured, and staged.

- Permits (LOTO, hot work, confined space, etc.) are known in advance.

- The job is estimated with realistic labor hours and duration.

- Any special tools, PPE, contractors, or documents are noted down.

Scheduling unready work is one of the fastest ways to destroy schedule compliance. Supervisors lose trust in the schedule, technicians lose time waiting, and planners lose any buffer to improve next week’s workload.

The five elements of a well-planned work order

A well-written work order removes uncertainty and makes the job as “plug-and-play” as possible for the technician. At a minimum, every planned job should include these five elements:

- Scope and craft: Define exactly what needs to be done, why it’s needed, and which craft or skill set is required. Clear scope prevents scope creep, misunderstandings, and unnecessary work. It also helps schedulers assign the right people for the job.

- Job steps and safety notes: Break the job into clear, logical steps. Include relevant maintenance SOPs and safety instructions.

- Parts and materials: All parts should be identified, ordered, and ideally kitted before the job ever hits the schedule.

- Permits and documents: Whether it’s a LOTO card, hot work permit, equipment drawings, or job plans, the planner should make sure these documents are available and accessible.

- 5. Labor and duration estimates: Realistic labor estimates are key for building reliable schedules. They don’t need to be perfect — just grounded in experience, feedback, and past actuals.

Improving planning accuracy over time

Planning is a cycle that improves only when feedback flows consistently.

Post-job feedback is your best data source. After a job is executed, the technician’s notes are gold. Actual hours vs. estimated hours, missing materials, unclear steps — this information helps planners tighten future estimates and avoid repeating the same mistakes.

If you have standardized procedures, when it makes sense, that feedback should result in an update to those SOPs or work order templates.

Aside from feedback, you should work on maintaining a healthy planning backlog — one prioritized by asset criticality, safety risk, and downtime opportunities. Planners should always know which jobs to prepare next, keeping the “ready” backlog full enough for schedulers to build a stable weekly schedule.

Common work order planning pitfalls

1. Planning from the desk without field verification

- Problem: Critical details get missed — clearances, access issues, special tools, actual asset condition

- Solution: Build a “field-first planning” rule. Planners verify scope in the field for all non-routine work. Even a quick walk-through prevents hours of rework later.

2. Incomplete material staging

- Problem: Technicians waste wrench time hunting for parts or making multiple trips to the storeroom.

- Solution: Use kitting and staging. Work doesn’t move to “ready-to-schedule” unless all materials are available, kitted, and clearly labeled.

3. Over-detailed planning that slows throughput

- Problem: Planners get stuck writing overly complex job plans, reducing the number of jobs they can prepare.

- Solution: Add details where it matters — safety, special tools, sequence of work, and critical checks. Routine or simple jobs only need essential guidance.

4. Lack of communication with the storeroom and operations

- Problem: Parts don’t arrive on time, priorities shift without warning, and schedulers get blindsided.

- Solution: Hold short weekly touchpoints: one with the storeroom for parts status, one with operations for priority alignment. Small meetings prevent big problems.

5. “We’re too busy to plan” mindset

- Problem: Everything becomes urgent, and planners end up reacting instead of preparing future work.

- Solution: Protect planner time. Remove them from daily firefighting, and track planned vs. unplanned work ratio to reinforce the value of planning discipline.

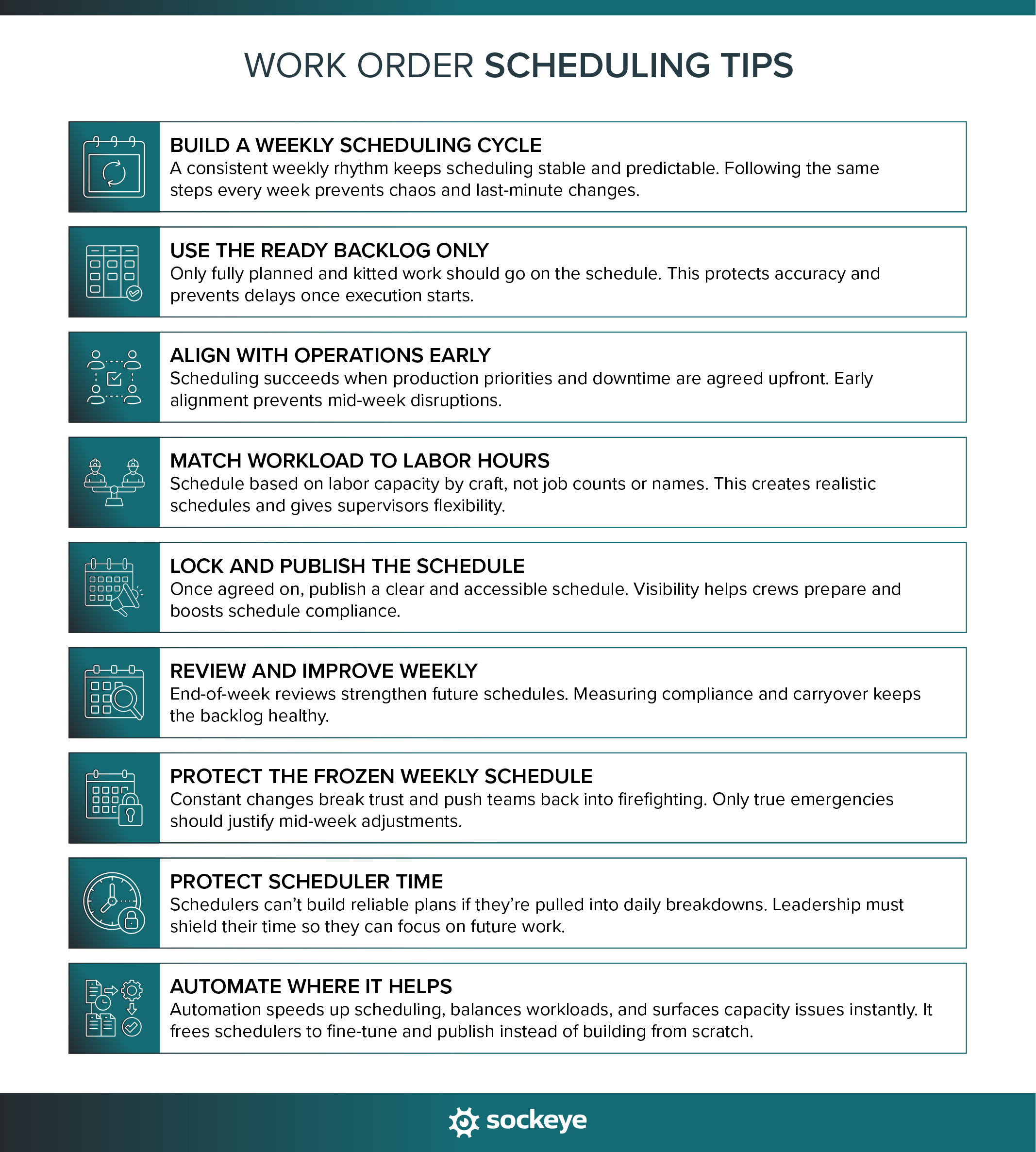

Work order scheduling done right

If planning makes the work executable, scheduling makes the work predictable. A good scheduling process turns a pile of work orders into structured weekly and daily plans that crews can rely on.As with planning, effective maintenance scheduling also requires a lot of discipline.

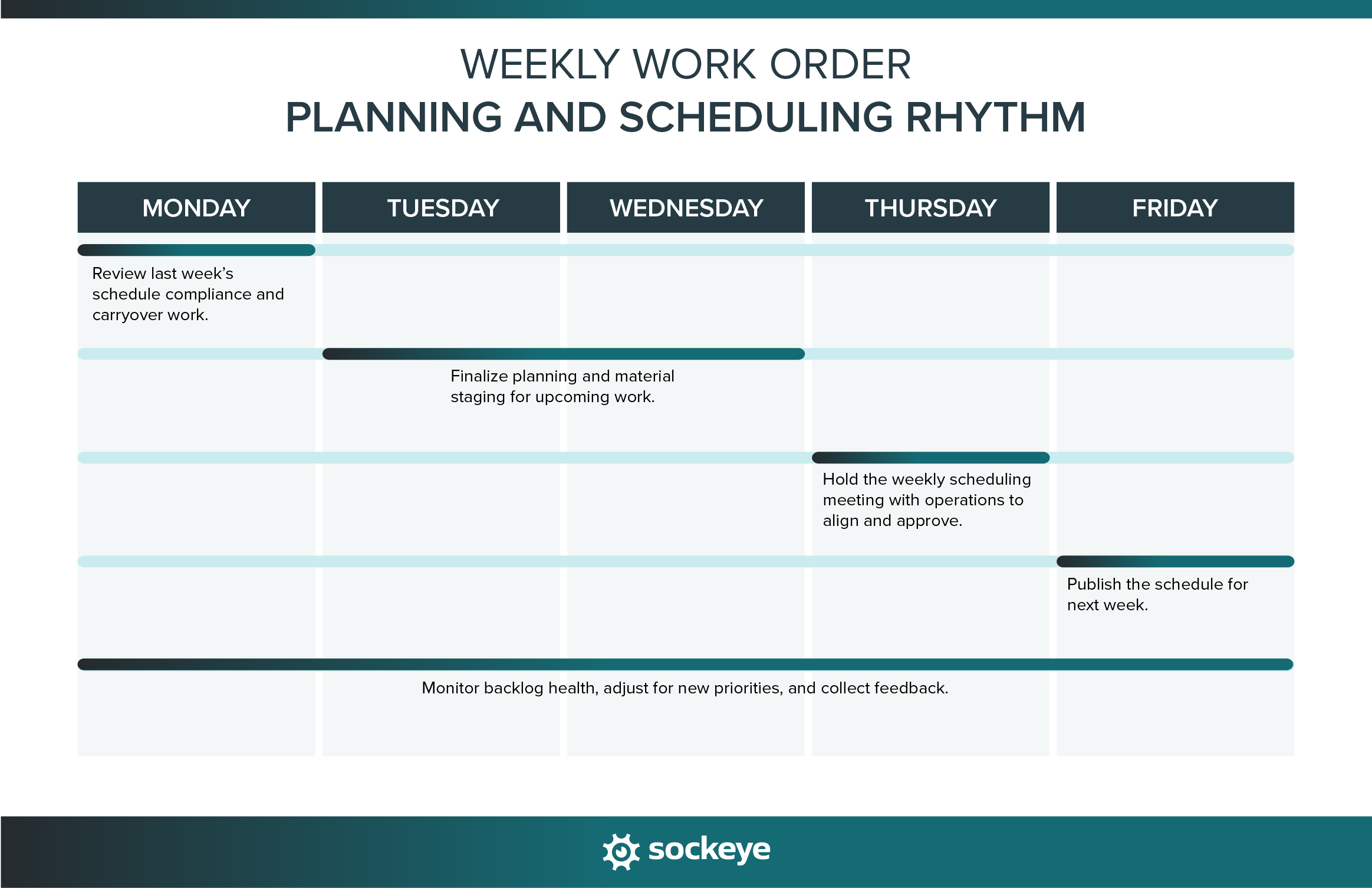

Building a weekly scheduling cycle

The weekly scheduling cycle is the backbone of a controlled maintenance workflow. In a busy plant, it should look something like this:

- Gather the ready backlog: Pull only fully planned, fully kitted work orders. If it’s not ready, it doesn’t go on the schedule. This protects schedule accuracy.

- Review with operations: Align on priorities, required downtime, and any production constraints. Operations buy-in is what keeps the schedule from blowing up mid-week.

- Build the schedule: Match workload to available labor hours by craft or crew. Focus on hours, not specific names, so supervisors have flexibility.

- Lock and publish: Once the schedule is agreed on, publish it. Having a clear and visual schedule that is easily accessible gives everyone time to prepare.

- Execute and review: At the end of the week, measure schedule compliance, review carryover, and update backlog status. This closes the loop and improves next week’s schedule.

Keys to effective work order scheduling

Effective scheduling is all about creating a realistic, executable plan that maximizes labor efficiency without overloading crews:

- Schedule 100% of available labor hours and target 80–90% completion. A full schedule provides structure, while the 80–90% target accounts for natural variability like minor breakdowns or carryover.

- Account for meetings, training, travel time, and known carryover. These fixed time drains add up. Ignoring them will lead to overloaded schedules and lower compliance.

- Level workload by craft and crew. Use tools like Sockeye that provide real-time labor availability data to balance labor hours across teams.

- Coordinate with production on shared resources and downtime windows. Early alignment prevents last-minute schedule changes caused by equipment (un)availability or operational priorities.

Avoiding common scheduling traps

1. “Wish list” schedules that ignore resource constraints

- Problem: Schedules exceed available labor or rely on optimistic assumptions, leading to constant carryover.

- Solution: Build schedules based on labor hours, not job counts. Validate capacity by craft before locking in the plan.

2. Scheduling unready work

- Problem: Jobs hit the schedule without parts, permits, or clear scope, causing delays and killing compliance.

- Solution: Enforce a strict “ready-to-schedule only” rule. If materials aren’t staged and the plan isn’t complete, it doesn’t get scheduled — no exceptions.

3. Constant mid-week changes

- Problem: Supervisors stop trusting the schedule, and crews return to a reactive mindset.

- Solution: Establish a “frozen weekly schedule” policy. Only true emergencies justify breaking the schedule once the week begins.

4. Lack of communication between schedulers and supervisors

- Problem: Supervisors get blindsided by changes or unclear priorities, resulting in inefficient execution.

- Solution: Hold a brief weekly handoff meeting to review the schedule, clarify expectations, and confirm labor availability.

5. Not protecting planner/scheduler time from daily chaos

- Problem: They get pulled into breakdowns and interruptions, weakening both planning and scheduling discipline.

- Solution: Leadership should treat planner and scheduler time as protected roles. Keep them out of day-to-day firefighting so they can focus on future work.

Tools for better work order scheduling

Most CMMS/EAM systems are excellent for storing asset data, managing parts, and tracking work history — but they make scheduling too rigid or complex. As a result, schedulers often get stuck wrestling with clunky interfaces, spreadsheets, and endless copy-paste work.

That’s where a scheduling and reporting add-on like Sockeye makes a real difference. It brings speed, visibility, and automation to the weekly scheduling process through:

- Two-way integration with CMMS/EAM systems: All work order data stays synchronized automatically, so schedulers always see the latest priorities, labor estimates, and job details.

- Scheduling automation that cuts effort by up to 90%: Instead of building schedules manually, automation handles the heavy lifting — leaving schedulers with fine-tuning and publishing.

- Drag-and-drop scheduling with real-time workload visibility: Schedulers can instantly see labor capacity by craft, team, or individual — making it easy to avoid overload and smooth out the weekly plan.

- Automatic load leveling between teams and crews: When using automation, the system distributes work evenly. When you schedule or reschedule work manually, you get visual notifications if someone is scheduled over capacity.

- Automatic reporting of scheduling-related KPIs: Schedule compliance, backlog, planned vs unplanned work done, labor utilization, delay codes, custom KPIs — everything is visible in a split-pane window or can be exported to your favorite BI tool.

Tools don’t replace planning and scheduling discipline, but they make good habits easier to practice and sustain. Sockeye, in particular, removes the friction that slows schedulers down and keeps the weekly scheduling process moving smoothly.

WO planning and scheduling metrics that matter

The right metrics give planners, schedulers, and supervisors a shared understanding of how well the process is working. Standard metrics to track include:

- Maintenance schedule compliance – % of scheduled work completed as planned. High compliance shows the schedule is realistic and protected. Low compliance usually signals unready work, poor coordination with operations, or frequent mid-week changes.

- Wrench time – % of technician time spent on actual tools-on work. Strong planning directly improves wrench time. Missing parts, unclear job steps, and poor staging all show up as lost wrench time.

- Planned vs. unplanned work ratio – target 80%+ planned. This metric shows how effectively the team is controlling the workload. A low ratio means the plant is still reactive; a high ratio indicates stable planning and scheduling discipline.

- Backlog health – age, priority, and work type distribution. A healthy backlog has enough ready work to build schedules, clear prioritization, and limited “aging” work orders that haven’t been touched in two months.

- Custom KPIs: Many plants add custom indicators tailored to their processes — examples include planning accuracy (estimated vs. actual hours) and mean days from WO creation to “ready” status.

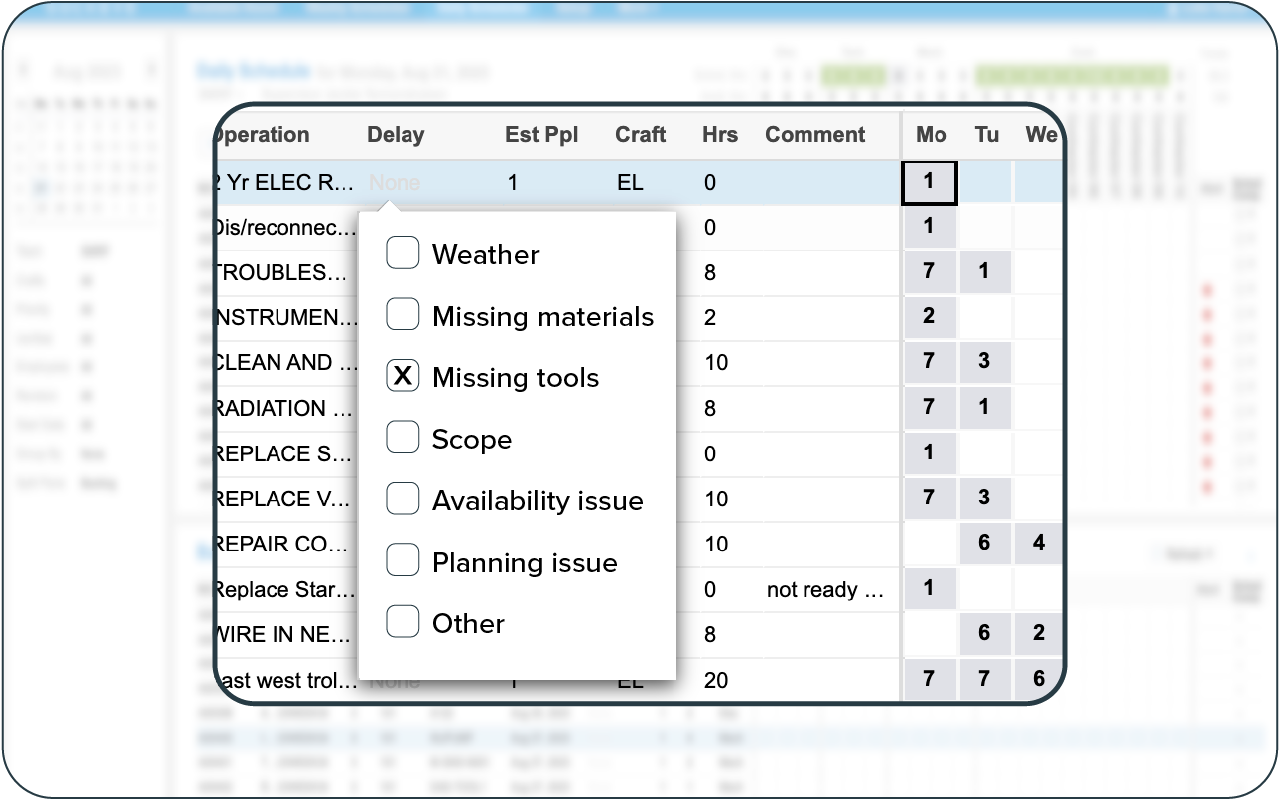

On top of that, you will want to track why work gets delayed so you can identify and address root causes. To streamline delay tracking, Sockeye provides a simple, customizable drop-down with common delay reasons:

Building a work order planning and scheduling discipline

A disciplined planner/scheduler can transform maintenance execution, but only when the culture allows them to focus on future work instead of daily emergencies.

The best approach is to start small: improve planning readiness, build realistic weekly schedules, and consistently gather feedback. Over time, these habits stabilize the workflow and shift the team from reactive to controlled. As the saying goes, “If you can schedule it, you can control it.”Visual scheduling tools like Sockeye help reinforce these habits. They make it easier to see workload, communicate the schedule, and reduce the manual effort that slows planners and schedulers down.

When the process becomes simpler, it becomes more consistent — and consistency is what drives reliability.

Want to see how Sockeye can support your planning and scheduling process?

Schedule a product demo and see why 98% of organizations that implement Sockeye continue using it long-term.