Approvals ensure that every job request is reviewed for necessity, safety, and cost before any time or budget is spent on it.

A well-structured work order approval process ensures that requests don’t pile up, that required work can be scheduled promptly, and that everyone — from requesters to supervisors — knows exactly where a work order stands.

Let’s explore how to transform WO approvals from a source of red tape into a key control point that helps you stay organized, accountable, and efficient.

Where approvals fit into the larger work order process

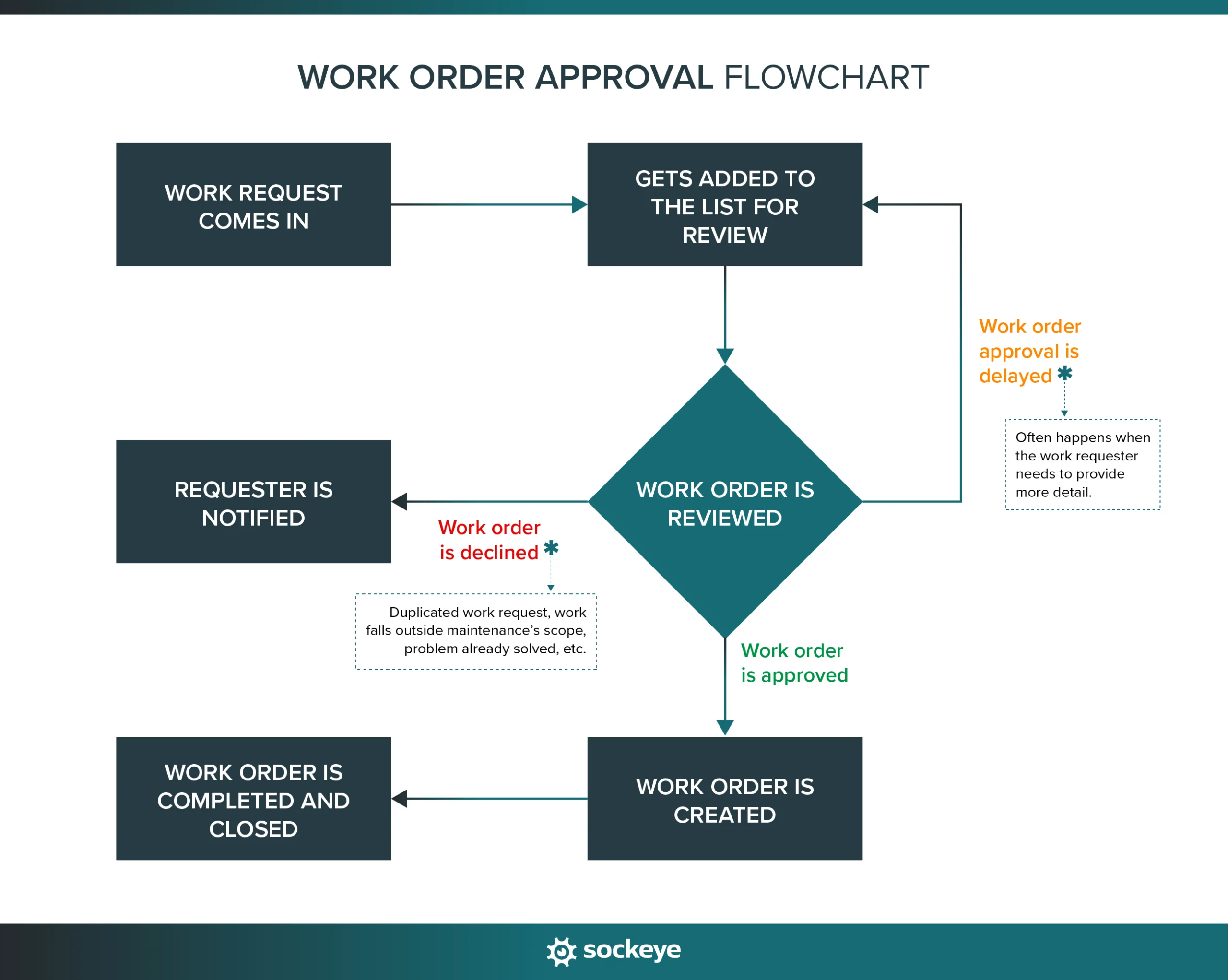

A work order goes through several stages before it’s closed: request → review → approval → scheduling → execution → closure → reporting.

Each step builds on the previous one, and skipping or rushing any of them can cause rework, delays, or wasted effort.

The approval step acts as the gatekeeper between planning and doing. It’s where managers confirm that the work is necessary, that it fits the maintenance plan and budget, and that safety or production won’t be compromised.

Without that checkpoint, you risk poor work order prioritization — working on low-priority or redundant tasks while critical issues wait in the queue.

Manual work order approval process

In a typical manual setup, the process looks something like this:

A maintenance request is submitted — maybe through a paper form, an email, or a shared spreadsheet. The supervisor reviews it, asks for clarification (if needed), then forwards it to a manager for sign-off. Approvals are often confirmed through a quick email reply or even a verbal “go ahead.” Once approved, someone manually updates the status, allowing the maintenance team to plan and schedule the job.

This approach can work in small operations, but comes with familiar pain points:

- Lost or buried emails — requests disappear in inboxes.

- Lack of visibility — requesters don’t know where their request stands.

- Approval bottlenecks — if a manager is out, everything stalls.

- Inconsistent documentation — makes audits, cost tracking, or performance reporting way harder than it needs to be.

Manual approvals rely heavily on people remembering to follow up and document decisions. Over time, that makes the entire process slow and unreliable.

Digital work order approval process

If you are using CMMS or EAM software, you most likely manage work orders (and their approvals) through your maintenance software.

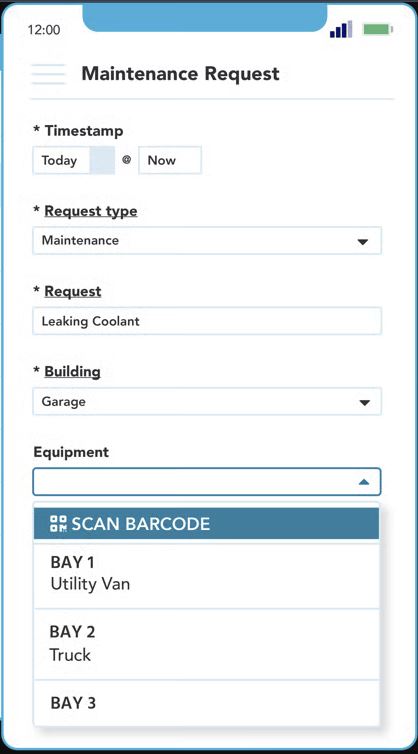

In this case, the process looks something close to this:

- The work request is submitted through a Work Request portal.

- The request is automatically routed to the right approver based on pre-set rules (like cost, asset type, or department).

- The approver gets an in-app notification. They can review the details submitted and request clarifications.

- Once approved or rejected, the decision is logged automatically — the software changes the status from Pending Approval to Approved/Ready to Schedule and saves details like the approver’s name, timestamp, and comments.

- A maintenance planner/scheduler gets a notification that a WO is ready for the next step.

When implemented correctly, digital work order approvals make the process significantly faster, more transparent, and easier to scale as your maintenance operations grow.

Who is responsible for reviewing and approving work orders

Not every work order needs the same level of review. The right approver depends on:

- What kind of work it is: Preventive maintenance might be auto-approved, while corrective work may need review.

- How much it costs: For example, supervisors can approve anything under $3,000, while larger jobs need a manager’s sign-off.

- What assets are affected: The more vital the equipment (or effect on production), the higher the approval tier.

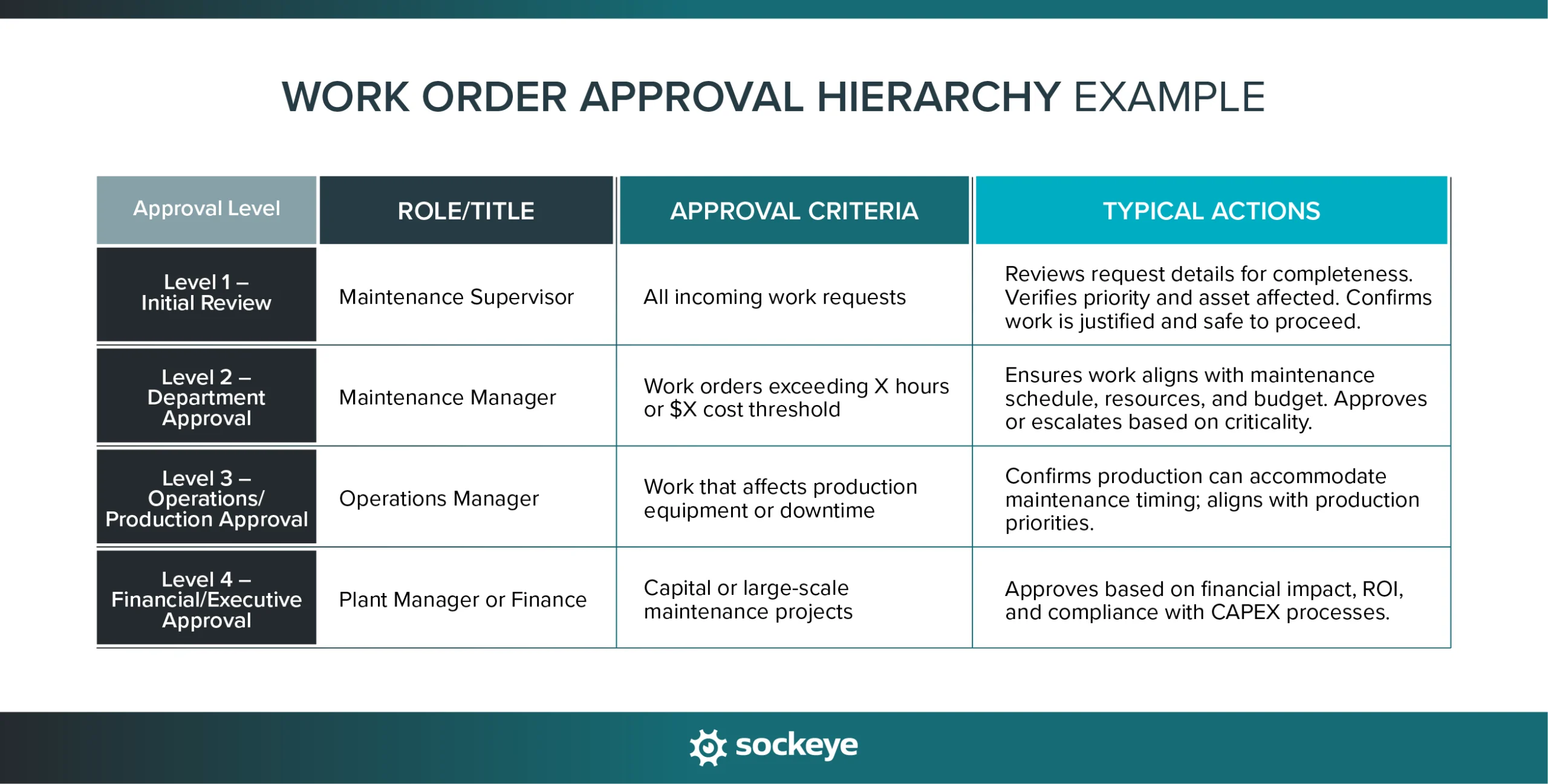

Here’s how it usually breaks down:

- Maintenance Supervisor: Reviews the technical details of the request. Checks if the issue is valid, if the scope is clear, and whether the team has the bandwidth or parts to complete it.

- Maintenance or Plant Manager: Looks at the bigger picture — budget, downtime impact, and alignment with maintenance priorities. Approves higher-cost or higher-risk work that goes beyond day-to-day maintenance.

- Operations or Production Manager: Gets involved when a job could affect production schedules or equipment availability. Helps balance maintenance needs with production goals.

Below is an example of a tiered work order approval hierarchy that a medium-sized manufacturing plant may use.

This kind of structure keeps approvals efficient — routine work moves quickly, while major jobs get the extra scrutiny they deserve. Be sure to adjust it to your team’s size, technology, and operational realities.

Best practices and prerequisites for an efficient WO approval process

A smooth work order approval process doesn’t happen by accident — it’s built on clear rules, consistent communication, and access to the right tools.

Define clear approval rules and thresholds

The fastest way to remove bottlenecks is to define exactly who approves what and when. Clear thresholds help avoid unnecessary back-and-forth and keep managers from being swamped with small, low-impact requests.

For example:

- Routine preventive work under $1,000 → auto-approved by supervisor.

- Corrective work between $1,000 and $5,000 → sent to the Maintenance Manager for review.

- Anything above $5,000 or affecting production → requires Plant Manager approval.

The cost thresholds, as well as people responsible for approving work orders, will vary from organization to organization. Nonetheless, the key lies in finding a practical balance between approval speed and cost control.

TIP: To speed up the process, you should also define clear rules for declining and delaying a work request. For example, declining duplicate requests or delaying requests that are missing specific details.

Standardize work order request forms

Approvers can only make quick, confident decisions if they have all the information they need up front.

The single best way to ensure that is to have a standardized work request submission form that covers name, description, and location of the problem, assets affected (equipment name or ID), and even requester details (name and contact info).

If you are using a modern CMMS, you can usually build a few different work request forms (that require different input fields) for various use cases.

Automate notifications and escalations

In most CMMS or EAM systems, you can set up automatic notifications and escalation rules to keep work moving:

- When a new request needs approval, the approver gets an instant alert (email, mobile push, or dashboard).

- If there’s no response within a set time — say, 48 hours — the system automatically escalates it to the next level (for example, from Maintenance Supervisor to Plant Manager).

- The requester can also see the live status of the WO, so they don’t have to chase updates.

Common mistakes to avoid

Even though WO approval is just one small step in the larger work order management process, it has a lot of room for error.

Here are some common pitfalls and how to avoid them:

- Overcomplicating approval hierarchies: Too many approval layers slow everything down and frustrate staff. Keep it simple — only involve extra reviewers when the cost or risk truly justifies it.

- Relying on email for critical decision points: Email threads get lost or buried, and they don’t create an auditable record. Use your CMMS or another centralized system to log approvals and comments.

- Failing to document approvals properly: Missing timestamps or unclear decision history make audits and cost reviews painful. Again, make sure every approval, delay or rejection is properly logged.

- Not revisiting thresholds as operations scale: Approval rules that worked when you had 200 assets might not work when you have 800. Review thresholds and approval roles at least once a year to keep them relevant.

- Not communicating workflow expectations: Everyone — from requesters to managers — should know how the process works.

What happens next with ready-to-schedule work orders?

Once a work order is approved, it moves from “pending” to “ready to schedule.” This is where the planning and scheduling phase begins — approved work is slotted into technician calendars, parts are ordered, and downtime is coordinated with production.

The approval step ensures that only necessary and properly reviewed jobs reach this stage. From there, an efficient scheduling process determines when and how the work will get done.

That’s where Sockeye comes in. Sockeye is a work order scheduling software that integrates directly with your existing EAM or CMMS. It pulls in approved, ready-to-schedule work orders and gives schedulers a super simple, visual interface to assign work and powerful automation to level workload between teams.

Instead of juggling spreadsheets or navigating through seven different screens in your CMMS, Sockeye lets you see everything in one place — backlog, priorities, crew and contractor availability, and the schedule itself.

Sockeye is perfect for organizations that already have a CMMS/EAM, but struggle to use it efficiently to schedule maintenance work. Using our two-way integration, you can simply outsource the scheduling function to Sockeye.

To learn more, schedule a quick product demo.