No matter how efficient your operation is, planned downtime is a fact of life in manufacturing. Whether it’s for preventive maintenance, equipment upgrades, or audits, machines will occasionally need to be taken offline.

The good news? Planned downtime is under your control — which means you can schedule and manage it in ways that minimize disruption to production.

In this article, we’ll break down a few planned downtime examples, share practical tips for scheduling and managing it, and show you how to track and calculate downtime. At the end, we will introduce a tool that can make downtime scheduling a whole lot easier.

What is planned downtime in manufacturing?

Planned downtime, also known as scheduled downtime, refers to any period when equipment or production lines are intentionally taken offline for a specific reason — typically for maintenance, upgrades, or other operational needs.

In most manufacturing environments, planned downtime is not only common — it’s necessary. It’s all part of keeping operations running efficiently and safely in the long term.

That said, how you manage planned downtime makes all the difference. Poorly scheduled or disorganized downtime can disrupt production just as much as a surprise breakdown. Let’s make sure that is not the case at your facility.

What is the difference between planned and unplanned downtime?

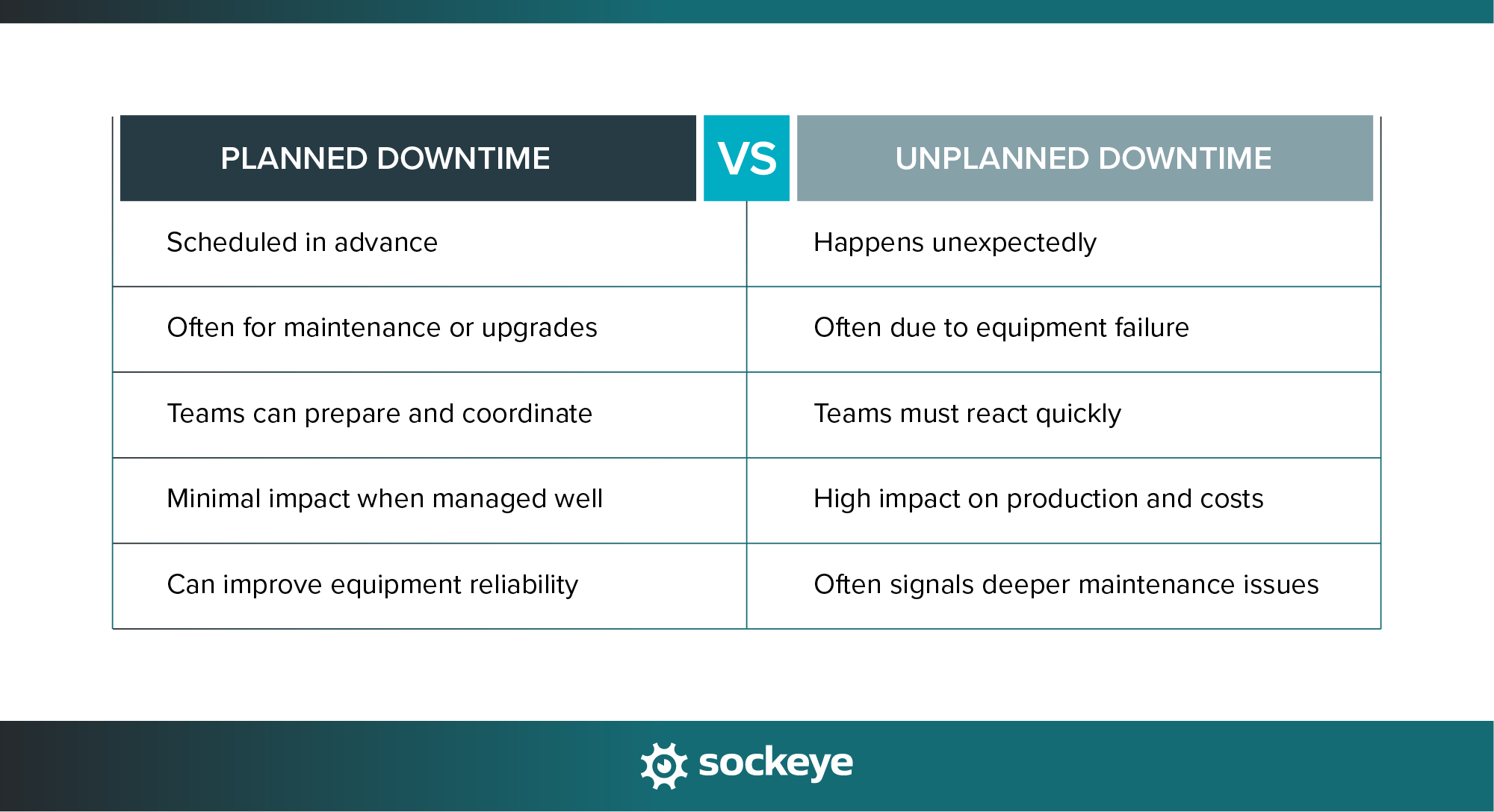

The key difference between planned and unplanned downtime comes down to control:

- Planned downtime is scheduled ahead of time and coordinated to reduce disruption.

- Unplanned downtime happens unexpectedly, usually due to equipment failure or other sudden issues — and it often causes major headaches.

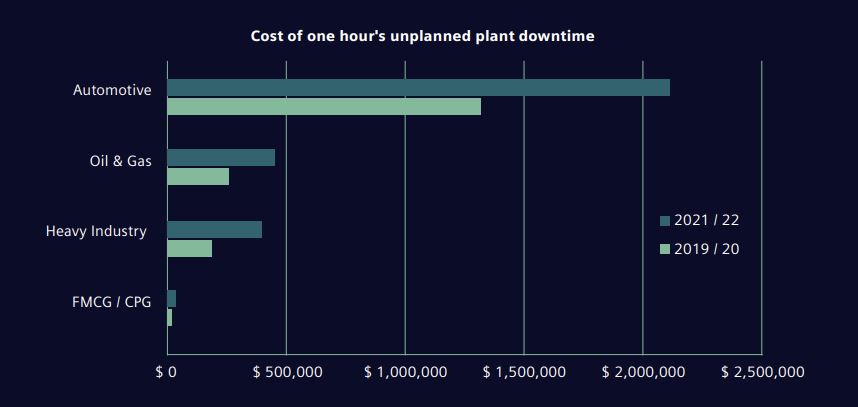

Based on the industry, Siemens research suggests that downtime costs manufacturers between $39k and $2 million per hour:

No wonder manufacturers are in a rush to minimize all types of downtime of all kinds. However, there is a point at which minimizing planned downtime causes an increase in planned downtime. Be careful not to cross that line.

Common planned downtime examples

Planned downtime is often tied to scheduled maintenance, but not exclusively. Here are the most common reasons manufacturers purposely slow down, pause, or stop production:

- Preventive maintenance: The machine is pulled out of production every quarter for bearing cleaning and lubrication to prevent wear and tear.

- Equipment upgrades or installation: A production line is shut down for two days to replace an outdated conveyor system with a newer, faster model.

- Changeovers: The packaging line is paused during a shift change to swap out molds and dies in preparation for a different product run.

- Quality assurance and calibrations: A critical filling machine is taken offline temporarily to calibrate sensors and ensure volume accuracy stays within tolerance.

- Operator training on new equipment: Machines are shut down for a few hours so staff can be trained on a newly installed robotic arm.

Other, less common reasons for planned downtime can include inventory counts, internal audits, planned shutdowns for energy management, and trial runs for process improvements (a line is taken offline for part of the day to test a new workflow designed to reduce material waste).

Tips for scheduling and managing planned downtime in manufacturing

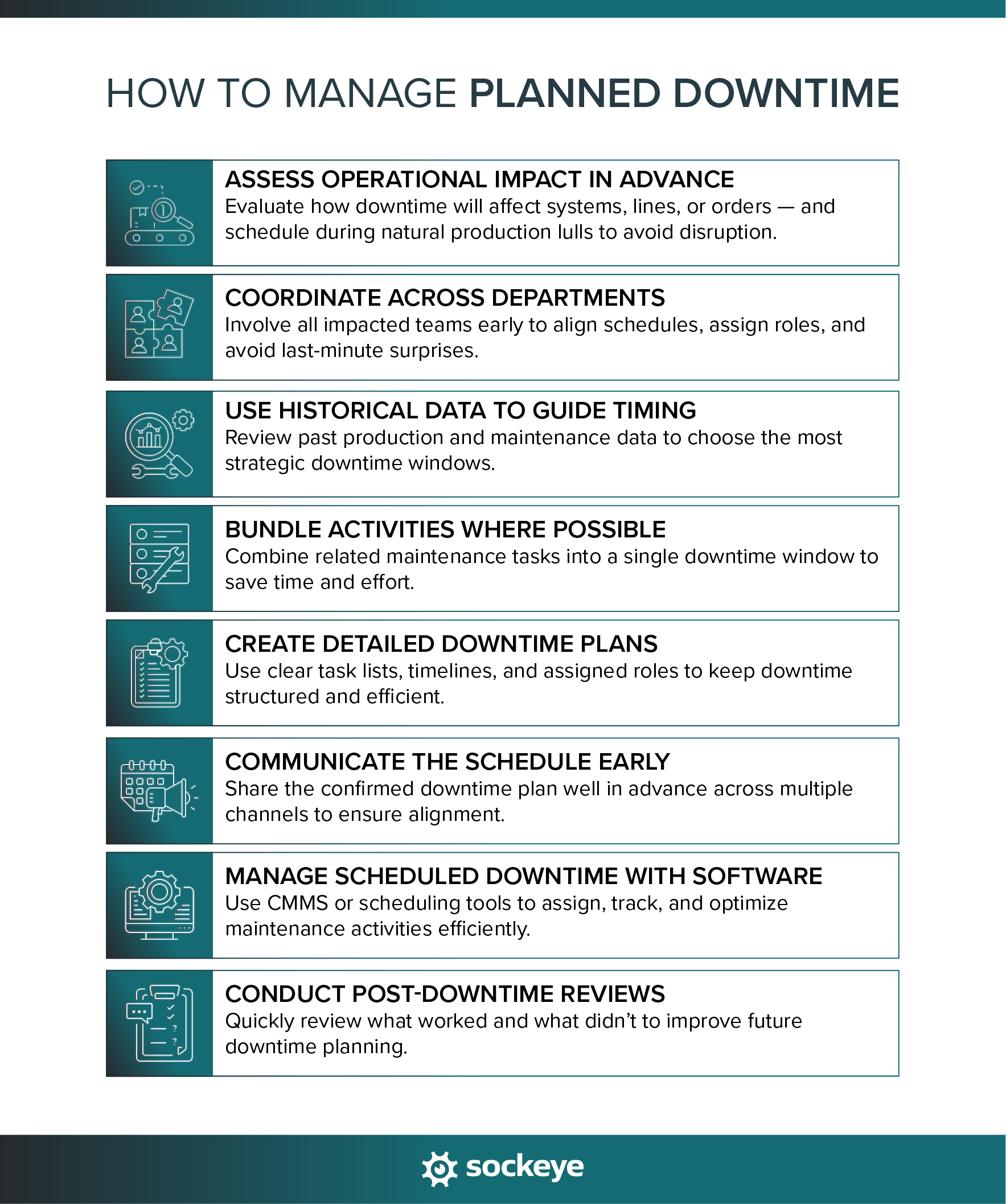

Even though planned downtime is necessary, how you schedule and manage it makes all the difference. So here are some proven strategies to help make your planned downtime smoother, more efficient, and less disruptive.

Sidenote: In large production plants, it will be up to the Reliability team to determine when and how often planned downtime is necessary. The maintenance planner and scheduler would use that information to schedule it officially.

1) Assess operational impact in advance

Before you schedule any downtime, take time to understand which systems, machines, or production lines will be affected — and how.

Start by reviewing your production schedule to identify natural lulls — like shift changes, weekends, or slow seasons — where downtime will have the least impact. A quick check-in with operations or production teams can also help flag any critical orders or customer deadlines that might clash with your timing.

If you’re using a CMMS, tag high-priority or “production-critical” machines so they stand out when planning. And always ask yourself: Can this task wait for a natural pause, or does it need to be fast-tracked?

When you assess the impact ahead of time, you reduce the risk of last-minute surprises and schedule conflicts.

2) Coordinate across departments

If you want it to go smoothly, make sure to get the right people in the loop. If scheduled downtime affects them in any way, production, quality, supply chain, and IT should all be aware of the plan. This prevents surprises and helps each team prep in advance.

Here are a few ways to make cross-team coordination easier:

- Set a regular downtime planning meeting. Even a 15-minute monthly check-in can help align schedules and priorities.

- Use shared calendars or scheduling tools. Visibility makes it easier for other departments to work around downtime.

- Create a downtime checklist for each team. This ensures everyone knows what they need to do before, during, and after the event.

- Designate a point person. At least one person should own the downtime plan and be the go-to contact for updates or changes. In larger facilities, you will often need one point person in each area, on each shift — sometimes even one person per trade/craft/specialty.

Good coordination is a great way to build trust between teams.

3) Use historical data to guide timing

Your maintenance logs and production data can tell you a lot about when machines are typically under less stress or when operations naturally slow down.

Look back at your records to spot patterns:

- Are there certain months or weeks when demand drops?

- Do some machines tend to break down around the same usage hours?

- When was the last time this line had a major maintenance window — and what happened?

By identifying these trends, your reliability and scheduling teams can align planned downtime with slower production periods.

There are several ways to do that. Review past downtime reports to see when similar work was done and what the outcomes were. Compare production volume data to find slower shifts or seasons that are better suited for maintenance. Track maintenance cycles for critical assets to avoid stacking too much work in a short period.

Using data-driven timing takes the guesswork out of scheduling — and gives your team a clearer path for proactive maintenance planning.

4) Bundle activities where possible

Every time you stop a machine, you’re creating a window — and it’s smart to make the most of that window. Instead of scheduling separate downtime events for every little task, look for opportunities to combine related work into one well-planned block.

Let’s say you’ve scheduled a shutdown to replace a pump. While that machine is offline anyway, why not also:

- Inspect nearby components that are normally hard to access.

- Run calibrations on connected systems.

- Upgrade any software or firmware tied to the equipment.

Bundling tasks like this helps you reduce the overall number of planned shutdowns, save on labor by consolidating resources, and get more done during each scheduled event.

The key is to plan ahead. Review your backlog, see what’s due or coming up soon, and look for logical groupings. With the right prep, you can turn one downtime window into a productivity win.

5) Create detailed downtime plans

Once the date is locked in, don’t leave the rest to chance. A successful downtime event starts with a clear, detailed plan. At minimum, it should cover:

- What tasks will be done

- Who’s responsible for each task

- How long each task is expected to take

- What tools, parts, or permits are needed

- What to do if something goes wrong (i.e., a part doesn’t arrive on time or work takes longer than expected).

Even a short 2-hour window can go sideways if roles aren’t clear or people are scrambling for materials. Use a simple checklist or task sequence to keep the team organized and on track.

The more structured your plan, the more productive your downtime.

6) Communicate the schedule early

Communicate big shutdowns clearly and communicate early. Once the schedule is confirmed, notify all affected teams. This gives them time to adjust workloads, reroute materials, or finish critical tasks.

To make sure your message sticks:

- Send a formal notice (email, calendar invite, or message through your plant’s system).

- Post the schedule in shared work areas or digital dashboards. If you use a maintenance scheduling app like Sockeye, everyone with an account can log in to see the live (read up-to-date) schedule, which keeps everyone aligned.

- Mention it in daily or weekly team meetings.

- Include what’s happening, when, and who to contact with questions.

And don’t assume one reminder is enough — send a quick heads-up closer to the date.

7) Manage scheduled downtime with software

Trying to manage downtime — or maintenance scheduling in general — with spreadsheets, emails, or sticky notes? That might work for a while — but it doesn’t scale and it is full of errors.

That’s where software tools like CMMS (Computerized Maintenance Management Systems), EAM (Enterprise Asset Management), or MES (Manufacturing Execution Systems) come in.

These systems typically let you schedule downtime tasks and assign them to specific technicians, track progress in real time, store documentation and maintenance history, and, ensure compliance with safety and regulatory standards.

However, due to their clunky interface and design, they also make scheduling harder than it needs to be. If your team is spending hours every week figuring out who’s available and when, consider using a scheduling add-on like Sockeye. It pulls in real-time labor availability, shows conflicts, and lets you schedule work in minutes instead of hours.

The right software doesn’t just organize your downtime — it gives you back time to actually plan and optimize it.

8) Conduct post-downtime reviews

Once the work is done and the equipment is back online, don’t just move on. Take a few minutes to review how things went — what worked, what didn’t, and what could be improved for next time.

You don’t need a long meeting. A quick huddle with the involved team can surface valuable insights:

- Were all tasks completed as planned?

- Did anything take longer than expected?

- Were there any surprises, delays, or missing resources?

- What could we do better next time?

Log any findings. This creates a feedback loop that improves future planning, reduces repeated mistakes, and helps your entire team get sharper.

How to track and calculate planned downtime?

There are a few good reasons to track planned downtime:

- To benchmark how much time is spent on maintenance vs. production.

- To spot inefficiencies in how downtime is scheduled or executed.

- To justify improvements (new tools, training, or process changes).

- To support audits and compliance in regulated industries.

Even though planned downtime is intentional, too much of it — or poorly timed windows — can quietly drag down output.

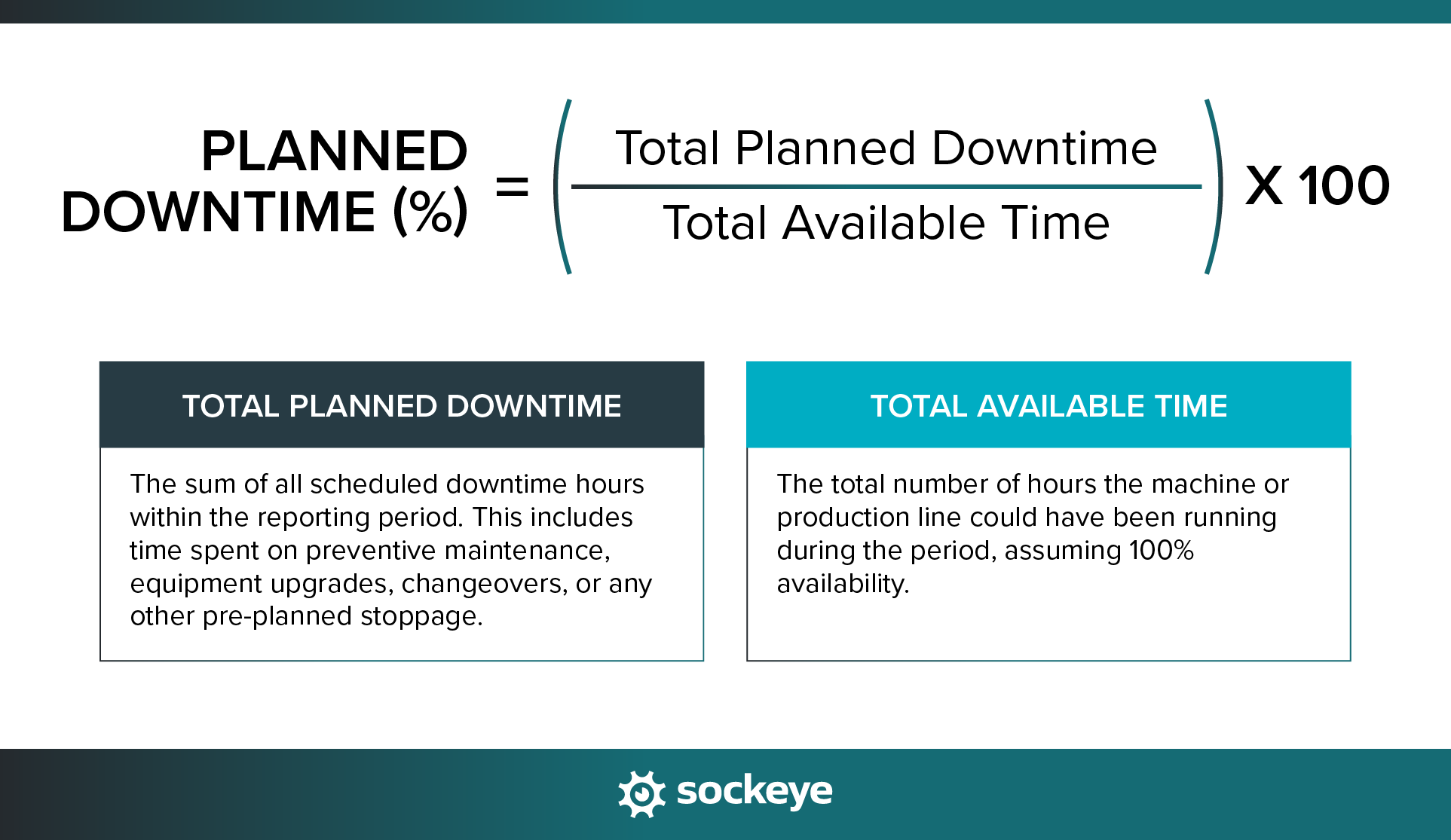

Planned downtime is commonly expressed as a percentage of total available time — this gives you a clear sense of how much of your potential production time is being intentionally used for scheduled work.

Here’s the formula to calculate Planned Downtime Percentage:

Let’s say a packaging machine is available for 720 hours in a month (24 hours × 30 days). During that month, it was taken offline for the following planned activities:

- 18 hours for preventive maintenance and equipment upgrades

- 12 hours for product changeovers

- 6 hours for quality assurance calibrations

That is a total of 36 hours of planned downtime.

Now plug it into the formula:

Planned Downtime = (Total Planned Downtime / Total Available Time) × 100

Planned Downtime = (36/72) x 100

Planned Downtime = 5%

So, the planned downtime for that machine was 5% of the total available time. This number helps you assess whether you’re within acceptable limits, compare performance across equipment, and spot trends that may require schedule changes.

Lastly, the best way to track planned downtime depends on your operation. Smart approaches include:

- Track by asset or line: Know which machines are down and how often. This helps you pinpoint bottlenecks or chronic time drains.

- Group by downtime type: Maintenance, upgrades, audits, changeovers — track them separately so you can analyze what’s taking the most time.

- Log by time period: Monthly tracking helps catch trends early. Quarterly or yearly summaries give a big-picture view for leadership and budgeting.

If you are using CMMS or EAM, some of this tracking could be automated. Still, make sure the data is being entered consistently when done manually.

Simplify scheduled maintenance with Sockeye

In many plants, the planner and scheduler are the same person, and most of their day is spent just trying to fit jobs into an already tight calendar.

That’s where Sockeye comes in.

Sockeye is a scheduling bolt-on that works alongside your existing CMMS or EAM system. It’s designed to make downtime and maintenance scheduling fast, simple, and visual — no more dragging work orders across endless calendar views or second-guessing technician availability.

You can schedule work in minutes instead of hours, and make sure your schedule reflects real-time crew and contractor availability.

When scheduling is faster and clearer, you get more time to actually plan — to look ahead, bundle tasks, create detailed job plans, and reduce unnecessary downtime.

Want to see how easy downtime scheduling can be? Schedule a quick demo with our team. Describe your situation — and they will show you how Sockeye can help.