1. Executive summary

JD Edwards (JDE) is a powerful platform, but when it comes to maintenance scheduling, many organizations find themselves limited by its built-in tools. Its maintenance users often struggle with cumbersome rescheduling processes, poor visibility into workloads, and time-consuming manual efforts to build weekly schedules. As a result, schedules are inconsistent, resources are underutilized, and productivity suffers.

Sockeye was purpose-built for work order scheduling and is designed to integrate seamlessly with JDE, eliminating these inefficiencies. It doesn’t replace JDE — it enhances it. With an intuitive interface, drag-and-drop functionality, and intelligent automation, Sockeye makes it easy to create, adjust, and execute maintenance schedules that reflect real-world constraints, such as crew availability and changing priorities.

By simplifying scheduling workflows, Sockeye enables maintenance leaders to focus on planning rather than firefighting. The result: more consistent schedules, increased wrench time, measurable cost savings, and a higher volume of PMs being completed because more work is being scheduled.

In this whitepaper, we explore how integrating Sockeye with JDE makes your maintenance operation more agile, user-friendly, and cost-effective.

2. Why a dedicated scheduling tool?

JDE is a powerful platform that covers a huge area of operations. This complexity comes at a cost, both figuratively and literally. Because the system offers numerous options and screens, maintenance planners and schedulers struggle to navigate and use it effectively.

Scheduling is the most sensitive part of the maintenance process. When it’s done poorly or inconsistently, it has significant downstream effects, including lower productivity, increased downtime, and higher maintenance costs, among others.

A dedicated scheduling tool fixes that problem, allowing your organization to extract maximum value from its JDE investment — without needing to do any overhauls of the process or systems.

The following are the primary benefits of integrating JD Edwards with a bolt-on scheduler like Sockeye.

Improved efficiency for planners and schedulers

JDE stores the data, but Sockeye lets you act on it quickly. With an intuitive scheduling interface and powerful automation, planners and schedulers spend far less time wrangling WOs and PMs and far more time focusing on actual planning and prioritization. Based on our internal data, Sockeye helps reduce time spent on scheduling by up to 90%!

This leads to better job sequencing, fewer delays, and more work being scheduled and completed — all without adding headcount.

Better accuracy and consistency in weekly scheduling

Without intuitive tools or automation, it’s difficult to consistently create realistic, resource-balanced weekly schedules. As a result, teams may skip weekly scheduling altogether or do it inconsistently.

With Sockeye, teams can reliably build and publish achievable weekly schedules every week. They are able to load crews close to full capacity without overbooking — which directly translates into more work getting done while avoiding costly overtime.

This doesn’t — and shouldn’t — happen overnight. Sockeye measures crew utilization and provides an easy way to increase scheduled work each month. This helps teams gradually work their way up to a fully loaded schedule.

For example, an aluminum company began with just 37% of its available maintenance labor scheduled each month. After a year with Sockeye, they were consistently hitting 85% — and estimated they were getting 50% more work done as a result.

Availability-driven scheduling automation

Sockeye taps into real-world crew and contractor availability to automate smart scheduling decisions — something JDE doesn’t do natively. Sockeye pulls this availability from your HR/Workforce software (if available), or you can input your shift patterns directly into Sockeye. Those shift patterns are then easily updated to account for training, PTO, vacation, etc. — for both technicians and contractors.

This leads to fewer scheduling conflicts, more effective labor utilization, more scheduled work, and less overtime. It also gives managers the ability to quickly rebalance workloads between teams — which is essential to making efficient use of labor across the board.

Parkinson’s Law says that work expands to fill the time allotted for its completion. Doc Palmer, the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook, suggests loading the schedule to 100% of the week’s labor capacity to defeat it. Sockeye provides the means to do just that.

Faster rescheduling and response times

Adjusting the schedule in JDE after a breakdown or priority change is painful. Planners and schedulers have to reassign work manually, check capacity by hand, and hope they don’t miss a conflict while navigating through multiple screens.

Sockeye makes rescheduling fast and straightforward. Just drag a job to a new time or crew, and Sockeye automatically checks availability and keeps the plan within limits. That agility improves response times and helps teams stay in control — even when plans change.

3. Closing the gap between planning and scheduling

In theory, maintenance planning and scheduling are two distinct roles — planners focus on what work should be done, while schedulers determine when and by whom. In practice, though, many organizations combine the two into a single position due to staffing limits or historical structure.

The result? One person is responsible for job plan accuracy and daily schedule execution — which means something always gets deprioritized. Most often, that’s the planning.

The consequences of an overloaded planner/scheduler

When scheduling becomes reactive and is done manually, a planner/scheduler has less capacity to create detailed job plans, review upcoming work, or prepare for shutdowns. This leads to a ripple effect of inefficiency:

- Low job plan accuracy: Missing steps, unclear instructions, or incomplete BOMs.

- Poor parts kitting: Planners don’t have time to check stock or order parts in advance.

- Unavailable assets or labor: Work orders scheduled when the equipment or crew isn’t ready.

- Delayed or canceled work: Because of missing information or last-minute changes.

These issues lead to rework, wasted labor hours, increased downtime, and frustration across the maintenance team. Most importantly, they erode trust in the schedule — which makes it even harder to improve schedule compliance.

How Sockeye unlocks time for value-added work

One of the top reasons organizations choose Sockeye is to break this cycle. By eliminating the manual effort required to build and manage the schedule, the planner/scheduler gains back hours each week they can reallocate to high-impact planning activities, such as:

- Improving job plans and task sequences

- Verifying parts availability and kitting accuracy

- Reviewing backlog and identifying critical work

- Planning for upcoming shutdowns or large projects

- Analyzing historical schedule compliance and refining future plans.

Beyond freeing up time, Sockeye also creates a structured feedback loop that helps planners continuously improve. As work is completed, technicians can log delays, add comments to the work order, and note how long jobs actually took. This real-world data feeds back into the planning process — helping planners refine estimates and adjust labor allocations for future jobs.

Sockeye doesn’t just make scheduling faster — it gives planners the breathing room to do the proactive, value-generating work they were hired for.

4. Quantifying the value of using Sockeye

Let’s see how the aforementioned benefits and savings translate to a real-world use case.

SCENARIO: A medium-sized manufacturing plant

- 15 technicians with a $25 hourly rate

- 2 planners/schedulers with a $35 hourly rate

- Technician overtime multiplier: 1.5x = $37.50/hour

- Cost of downtime: $100,000/hour (a projection based on Siemens downtime research)

- Downtime estimate: The plant loses 25 hours a month to downtime (the average; based on the same study linked above)

- Annual parts inventory management spend: Assumed at $500,000

Productivity gains

Consider a medium-sized plant with 15 technicians and 2 planners or schedulers. By implementing Sockeye, companies typically cut scheduling time in half.

For this plant, that equates to saving 20 hours per planner per month — or 40 hours total.

Instead of spending that time manually building and adjusting schedules, planners can now focus on creating better job plans, improving work prioritization, and ensuring resource availability.

These planning improvements translate directly into better execution on the shop floor — fewer delays, fewer rework orders, and more completed jobs. Over time, this shift strengthens the entire maintenance process and raises overall schedule compliance.

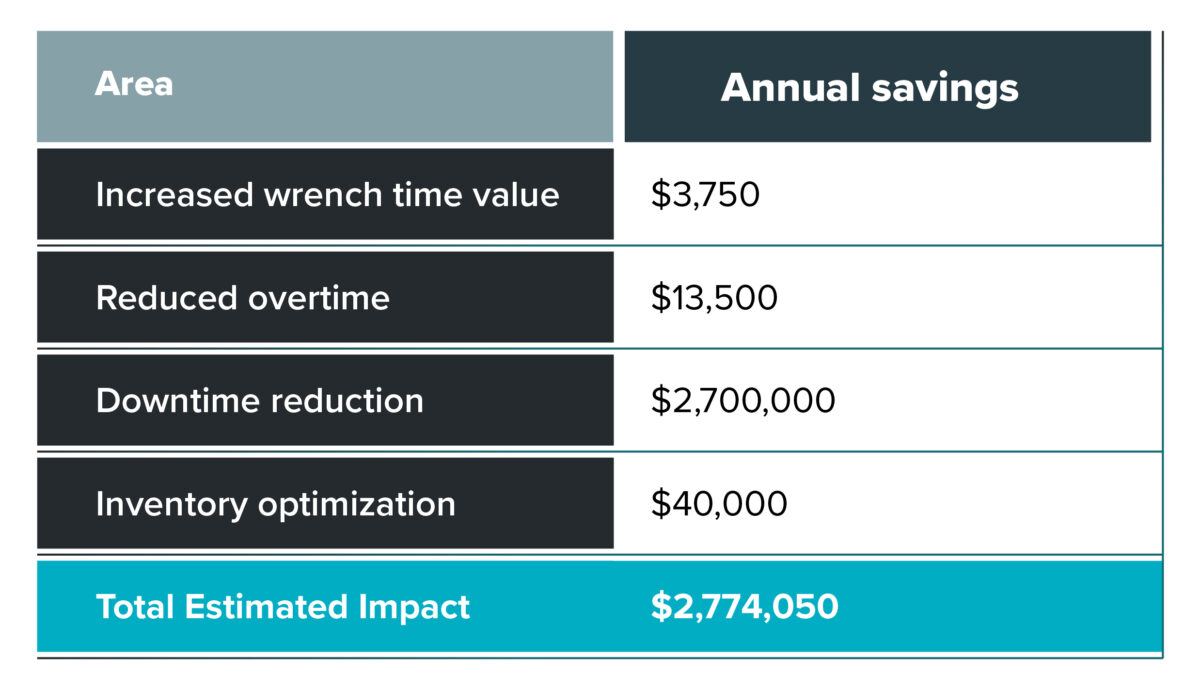

In parallel, Sockeye’s ability to improve schedule quality and consistency leads to higher technician utilization: A 10% increase in wrench time adds approximately 150 productive hours per year across a 15-person crew. At $25/hour, that represents $3,750 in additional labor value — not from hiring more staff, but from using current resources more effectively.

More wrench time doesn’t just mean more work completed — it means more planned preventive work completed. As teams gain time and consistency, they can address more PMs. This leads to more reliable assets with higher uptime.

Cost savings

Sockeye also drives cost reduction in three high-impact areas:

OVERTIME REDUCTION

With clearer, balanced schedules and real-time visibility into availability, teams can see overtime drop by 20% or more. If each technician typically logs 10 overtime hours per month, that’s 150 hours of overtime across the team. A 20% reduction saves 30 overtime hours monthly, or 360 annually. At an overtime rate of $37.50/hour, this results in $13,500 in annual savings.

REDUCED DOWNTIME

One of the largest — and most often overlooked — benefits comes from improved responsiveness and schedule consistency. Being able to consistently schedule and execute more preventive work usually leads to a noticeable reduction in downtime.

An average facility loses 25 hours per month to unplanned downtime. For this example, let us assume a 9% reduction (which equates to 2.25 hours saved monthly). At an estimated $100,000 per hour in downtime costs, that’s $225,000 in monthly savings, or a staggering $2.7 million annually.

INVENTORY COST OPTIMIZATION

Better planning and coordination also reduce the need to stockpile spare parts or rely on last-minute emergency orders. With a stable schedule and fewer unexpected breakdowns comes more predictable inventory consumption.

If annual inventory-related costs are around $500,000, even a modest 8% improvement — common for teams that transition and stick to a proactive schedule — leads to $40,000 in annual savings.

The summary of annual savings

Sockeye pays for itself quickly, and the value compounds as teams get more confident and consistent in their plans and schedules.

5. Sockeye + JDE: Two-way API integration

For maintenance leaders, some of the biggest concerns with adopting a new tool are the quality of integration, the speed of deployment, and user adoption.

Sockeye is uniquely designed to address all of those concerns.

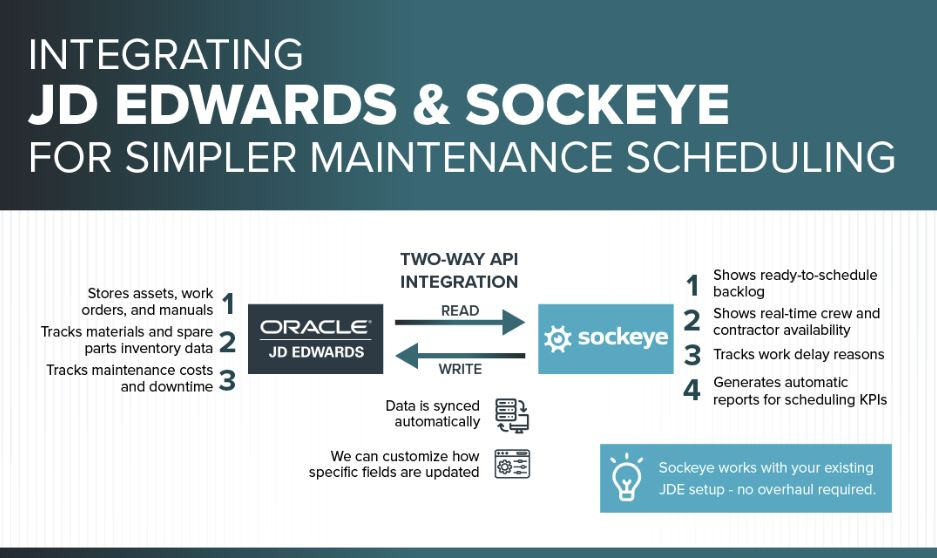

We connect directly to JDE through a two-way API integration. JDE tells Sockeye which work orders are ready to be scheduled — and Sockeye tells JDE when those are scheduled and done.

The exact data exchanged typically includes work order details and status, scheduling fields, and resource information (such as your workbooks, manuals, materials, etc.).

Once integrated, Sockeye remains in lockstep with JDE, ensuring that schedulers always work with the most current information. Whenever a work order is updated or its status changes — either in JDE or Sockeye — this change is immediately visible in both systems.

For organizations that prefer a more manual approach or want a one-way integration for specific security reasons, Sockeye can also be configured to support file-based integration using Excel. In this scenario, ready-to-schedule WOs and PMs are exported to a CSV file, which is then uploaded to Sockeye.

When a planner/scheduler opens Sockeye, they see a ready-to-schedule backlog. The way the backlog data is displayed and what data is accessed when you double-click a work order can both be customized according to your preference.

The IT teams love Sockeye for many different reasons:

- No custom JDE development required: Sockeye works with your existing setup — no need to modify your existing maintenance software in any way.

- Lightweight footprint: Sockeye is a cloud-based platform, so there’s no local software to install, patch, or maintain.

- Low lift for IT: IT only needs to provide API endpoints or database views for the initial setup — our team does the rest. After that, it’s a tool owned and operated by the maintenance team, not a long-term IT project.

- Secure and scalable: Sockeye is hosted on Microsoft Azure, which has industry-standard certifications (like ISO and SOC 2). It supports adding multiple sites and localizations (language, time zones, date formats, etc.).

A full production rollout with API integration takes 4 to 6 weeks, while a file-based integration can be done in under 2 weeks.

We also have a free 30-day trial available with no IT involvement required. Manufacturers use to confirm integration configuration and user adoption — meaning you can start scheduling and gain value right away.

Furthermore, schedulers can be trained to use Sockeye in just one hour. The training is conducted by former planners and schedulers who understand the daily challenges on the plant floor, so there is no need to hire consultants during implementation.

In other words, the integration process is heavily streamlined to simplify adoption for busy IT departments.

6. Conclusion: A smarter way to schedule with JDE

JD Edwards gives maintenance organizations a powerful foundation for asset management. But without an effective way to schedule and track maintenance work, much of its value remains untapped.

Sockeye bridges that gap.

By adding Sockeye as a dedicated scheduling layer on top of JDE, maintenance leaders gain the tools they need to consistently plan, adjust, and execute high-quality schedules — without complexity, workarounds, or IT involvement. The result is increased overall productivity, more wrench time for technicians, less downtime, and measurable cost savings.

Teams can finally transition from fragmented scheduling to a consistent, data-driven process that accomplishes more work and maximizes the value of the systems they’ve already invested in.

Interested in modernizing your JDE scheduling with Sockeye? Start the process by booking a demo with our team.