Many maintenance teams are still struggling with manual, Excel-based scheduling processes. But whiteboards, sticky notes, and spreadsheets simply don’t scale. Despite being extremely inefficient, they result in missed PMs and unbalanced workloads. You end up doing a lot of scheduling, and very little planning — which is a big problem when one person does both roles.

On the other end of the spectrum, some teams rely on large CMMS or EAM platforms with built-in scheduling modules that are far too complex or time-consuming to use day-to-day.

The truth is, scheduling sits at the heart of every successful maintenance program. It’s the bridge between planning and execution — the step that determines whether work actually gets done on time. Because of that, finding the right software to handle scheduling efficiently, accurately, and consistently is crucial.

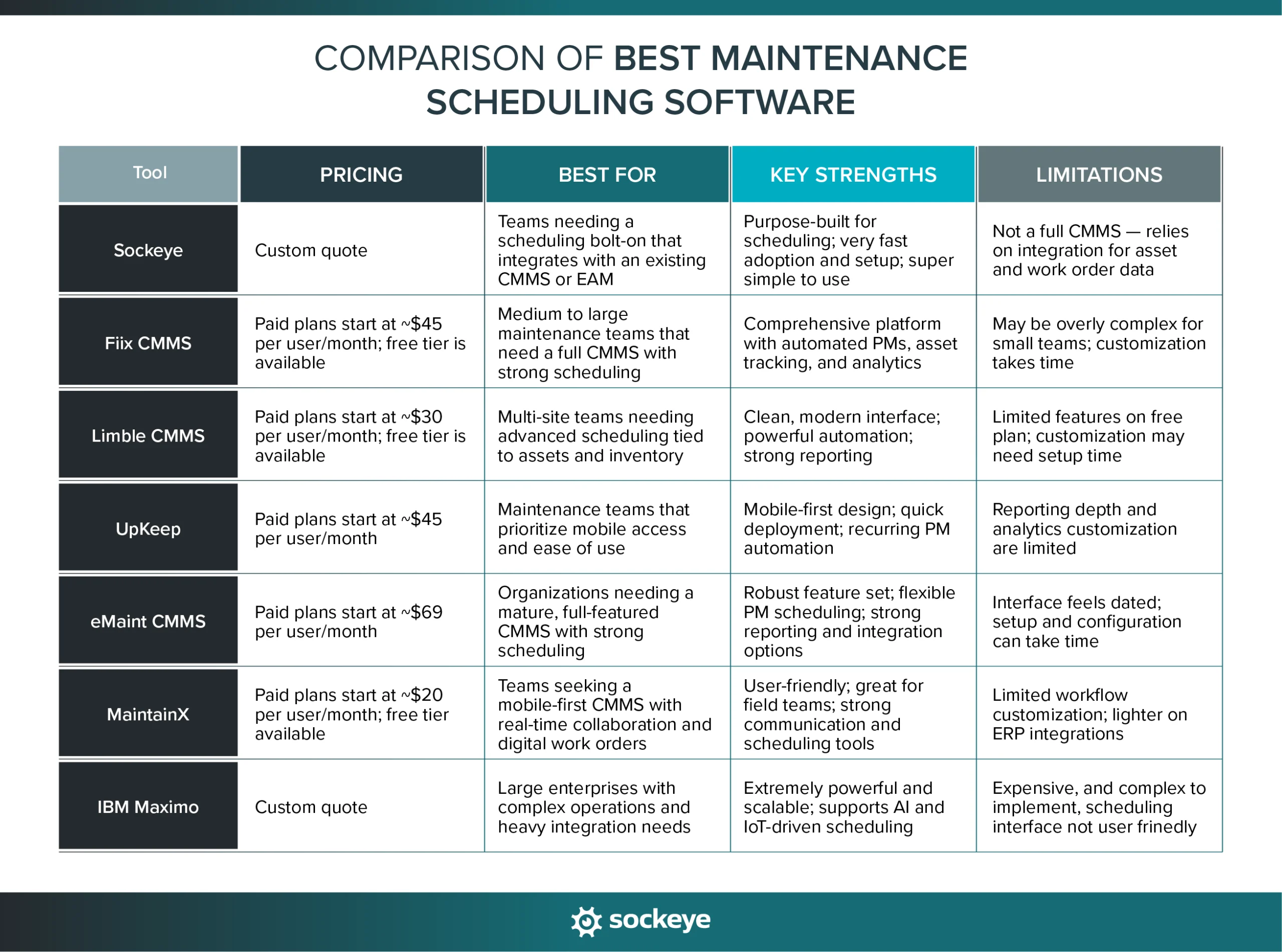

To make your search easier, we’ve reviewed the best maintenance scheduling software available today and narrowed it down to our top 7 picks. We will compare each solution based on key features, best use cases, potential limitations, real user reviews, and pricing models.

What to look for when evaluating maintenance scheduling software providers

Choosing the right maintenance scheduling software isn’t just about picking the one with the longest feature list. The best solutions are the ones that make the scheduling process simple and practical.

Here are the key features and characteristics to look at when reviewing different vendors.

Simplicity and ease-of-use

A scheduling tool is only valuable if people actually use it. We’ve seen too many maintenance departments try to use legacy CMMS systems or large enterprise platforms like SAP and Oracle EAM, only to revert to Excel because the scheduling modules take too long to learn or use.

The right maintenance scheduling solution should simplify and speed up your entire scheduling process — from assigning weekly PMs to slotting in emergency work. Look for software that offers:

- An intuitive interface: Drag-and-drop scheduling and rescheduling, ability to visualize the schedule, and minimal clicks to complete a task.

- Smart navigation: You shouldn’t need to jump through seven different screens just to find and reschedule a work order.

- Quick adoption: Technicians and planners should be able to learn the basics within hours, not weeks.

Scheduling automation

One of the biggest advantages of modern maintenance scheduling software is automation. Instead of spending hours every week updating calendars and assigning work orders, the right tool can handle a lot of that heavy lifting for you.

Good scheduling software helps you automate repetitive tasks and generate schedules that make sense for your team’s actual workload and availability. For example, the best platforms can:

- Automatically build balanced weekly and daily schedules based on technician skills and their real-time availability that minimize overtime and maximize scheduled work.

- Automatically create recurring schedules for preventive maintenance work.

- Send automatic reminders and updates to technicians when schedules change or new jobs are added.

Labor availability data

A maintenance schedule is useless if it does not reflect who’s actually available to do the work. That’s why a good maintenance scheduling software gives you real-time visibility into your team’s availability — both internal technicians and external contractors. Ideally, you should be able to edit availability manually to make sure you are always working with the latest data.

When you can see who’s on shift, who’s on vacation, and who’s already booked, you can create balanced schedules that maximize productivity while minimizing overtime.

KPI reporting

If your technician count is in double digits, you need access to reliable metrics to track performance, identify bottlenecks, and continuously improve your processes.

Look for software that can automatically generate reports for your key scheduling metrics like schedule compliance, backlog size, labor utilization, how much preventive vs reactive work you have been doing, and similar.

Beyond built-in dashboards, you should also be able to define custom KPIs and export data into your existing business intelligence software.

Your specific needs

Every maintenance team operates a little differently — which means the best maintenance scheduling software for one company might not be the best fit for another. So, before you start comparing platforms, define your specific needs and priorities.

Think about how your team works day to day, where your biggest scheduling challenges are, and what features would actually make your job easier. Think about:

- Offline capability: If it has mobile access, will the software still function when Wi-Fi or cellular connections drop?

- Type of solution: Do you need a complete maintenance software that includes scheduling, or just a scheduling bolt-on to connect with your existing system?

- Integration options: Can it connect with your other tools — like EAM, HR, or IoT sensor systems?

- Pricing and scalability: Does the cost structure make sense for your team size and expected growth?

Having these requirements clear upfront will make it much easier to evaluate your options.

Top 7 maintenance scheduling solutions

Some platforms are built for large enterprises with complex asset hierarchies, while others focus on making life easier for smaller maintenance teams that just want a faster, simpler way to plan and assign work.

Whether you’re looking for a lightweight scheduling bolt-on or a full-featured CMMS/EAM with integrated scheduling and reporting, this list will help you narrow down your options and find a solution that truly fits how your team works.

1. Sockeye — #1 Add-on for maintenance scheduling

Sockeye is a maintenance scheduling bolt-on built to complement your existing CMMS or EAM system rather than replace it. It simplifies and speeds up the schedule-building process — so you spend less time scheduling work and more time properly planning the jobs.

Best use case scenario: Sockeye is ideal for teams who already have a CMMS but struggle with the scheduling module (or revert to spreadsheets). They can outsource the scheduling functions to Sockeye without needing to replace the existing system.

Key features:

- Automated maintenance scheduling: Create weekly and daily schedule in minutes by letting Sockeye automatically match available labor to ready-to-schedule work orders.

- Drag-and-drop rescheduling: Quickly adjust existing schedules with a simple, visual interface. Just drag and drop the task in the next available slot.

- Live Labor Availability Dashboard: Easily edit, update, and manage technician and contractor availability to balance workloads and reduce overtime.

- Integrated KPI reporting: Create and track SMRP and custom KPIs based on verified data. You can auto-generate reports or forward the data to your BI software.

- Fast deployment: Go live in as little as one week with minimal setup and minimal IT involvement.

- Seamless integration with existing systems: Offers read/write API or file-based import; ties into CMMS/EAM & HR/labor systems so you’re not duplicating or siloing your data.

Potential limitations: While you can technically use it as a standalone scheduling solution, Sockeye works best when it is connected to existing CMMS or EAM software like SAP, JDE, Maximo, FMX, or any other.

Here is what existing users say about Sockeye:

“It shows the available work. It shows the available labor. It’s just a matter of clicking and dropping. It’s fantastic.” — Cade Schoonover, Assistant VP of Maintenance and Reliability at Cargill [FOOD MANUFACTURING]

“Sockeye’s greatest advantage is ease of scheduling. With a simple drag-and-drop, you can allocate workers. Scheduling used to take me hours to do for just one crew, and I planned schedules for six different crews. What used to take me up to five days of work can be now done with Sockeye in just under an hour.” — Todd Hicks, Planning and Shutdown Superintendent at the AV Group [PULP MANUFACTURING]

Pricing:

- Free plan: Not available

- Free trial: Yes, click here to start a 30-day free trial

- Paid plans: Subscription-based model; reach out to get a custom quote

2. FiiX CMMS

Fiix CMMS is one of the most widely used cloud-based maintenance management platforms, designed to help teams organize, schedule, and track maintenance work in one place. It offers powerful scheduling capabilities, intuitive dashboards, and strong integrations with other business tools.

Best use case scenario: Ideal for medium to large organizations that need a full CMMS with built-in scheduling, reporting, and asset management.

Key features:

- Calendar-based scheduling: Plan and assign PMs, inspections, and corrective tasks through a drag-and-drop interface.

- Automated work order creation: Recurring PMs are generated automatically based on time, usage, or condition triggers.

- Technician availability tracking: Shows labor hours, shifts, and assignments to avoid conflicts and overtime.

- Work request portal: Allows non-maintenance staff to submit requests that flow directly into the schedule.

- Integration flexibility: Connects with ERP, SCADA, and IoT systems for condition-based scheduling.

- Performance dashboards: Track KPIs like schedule compliance, downtime, and mean time between failures (MTBF).

“It’s helped us to organize our entire Asset tree for ease of access to PMs, warranties, maintenance schedules, and more. Our production team now has better communication with maintenance through the WO request system, enabling us to respond to breakdowns faster than ever.” — Joshua B. on G2

Potential limitations: Some users find the mobile app less intuitive for technicians in the field, and setup can take longer for large, multi-site organizations. Some users complain about clunkiness and issues with the reporting module.

“It’s a little slow when creating work orders. Working at a fast pace, technicians find it hard to fill out WOs. This skews the data in terms of analysis. The dashboard could do with the use of graphs.” — Jaabir L. on Capterra

“I find that the reports are the weak link in that they usually do not pull all data. I need to learn more about analytics to see if this improves the issue.” — Kellie G. on Capterra

Pricing:

- Free plan: Fiix offers a free tier with limited PMs and features

- Free trial: Not available

- Paid plans: Subscription-based model; basic tiers start at around $45 per user/month; enterprises can get a custom quote

3. Limble CMMS

Limble CMMS is a full-feature cloud-based maintenance management platform designed to bring clarity and control to asset, work order, inventory and scheduling workflows.

Best use case scenario: Ideal for maintenance managers in manufacturing, facilities, healthcare or multi-site operations who require strong preventive scheduling, asset history and inventory linkage — all in one system.

Key features:

- Calendar and list-based scheduling: Set up recurring PMs, drag and drop tasks, and get a clear visual timeline of all upcoming maintenance activities.

- Asset health tracking and work order history: Keep complete visibility into each asset’s past work, condition, and performance, ensuring better planning for future maintenance.

- Parts and inventory management: Link scheduled tasks to required spare parts, so materials are always available when work begins.

- Technician availability and workload balancing: View technician schedules, skills, and certifications to assign work more efficiently.

- Custom dashboards and reporting: Track KPIs such as PM compliance, MTBF, MTTR, and wrench time. Visualize trends across assets, sites, or teams.

- Integrations and automation: Connect Limble with IoT sensors, ERP systems, or BI tools to automate scheduling based on condition triggers or performance thresholds.

“The PM scheduling feature is another highlight, providing multiple levels of detail and ensuring scheduling aligns with site and condition needs. I also appreciate the ability to view Work Orders (WO) and PM history for each asset, which empowers our reliability team to analyze trends and identify problematic areas.” — Kevin E. on G2

“As the maintenance planner and scheduler i use this program most of my day and it is easy to use.” — Chris B. on G2

Potential limitations: Some users mention that they wish certain things were more customizable. While only few, there are reports of issues with WO and PM management.

“It is basically a solid platform for capturing new work requests and also closing out work. But anything in between (the planning and scheduling of work) will need to be done outside the system.” — Mads J. on Capterra

“There isn’t a way to “schedule” the guys for on call weekends so we know who should be taking calls.” — Lori B. on G2

Pricing

- Free plan: A basic free plan with limited functionality is available.

- Free trial: Not available

- Paid plans: Subscription-based model; advanced scheduling functionality locked behind higher tiers; you will have to reach out to get a custom quote

4. Upkeep

UpKeep is one of the most popular mobile-first CMMS solutions, designed to make maintenance scheduling and work management simple and accessible from anywhere. It’s built for teams that want an easy-to-use platform that connects planners, technicians, and managers.

Best use case scenario: Best for maintenance teams that need a fully featured CMMS with strong mobile capabilities and an intuitive interface for scheduling, tracking, and reporting maintenance work.

Key features:

- Visual work order scheduling: Easily plan, assign, and prioritize maintenance tasks using a clean calendar or list view.

- Mobile-first access: Technicians can receive work orders, update progress, and close jobs directly from their phones or tablets — even capture photos and notes on the go.

- Automated PM scheduling: Set recurring preventive tasks based on time, usage, or condition triggers to reduce reactive maintenance.

- Inventory and parts tracking: Link scheduled jobs with available parts to avoid stockouts and improve planning accuracy.

- Team collaboration and notifications: Keep everyone updated with real-time alerts, chat, and push notifications.

- Analytics and KPI dashboards: Measure schedule compliance, response times, and downtime metrics to continuously improve performance.

“The user interface is intuitive, and the mobile app is particularly useful for on-the-go updates. The work order management and asset tracking functionalities are standout features, making it easy to keep everything organized.” — Manju B. on Capterra

Potential limitations: UpKeep’s reporting, scheduling, and analytics, while easy to use, may not be as customizable as those in more advanced enterprise systems.

“The scheduling options for recurring work orders is totally bad. The fact that you can’t schedule seasonal tasks without some silly back-end procedure to duplicate the work orders every year is highly frustrating.” — Jamie P. on Capterra

“When you mark one thing as failed on a task list instead of just made a work order for that individual item it will creat individual work orders for everything in our PM. Some of our machines have over 50 things to do, so now there’s 50 work orders I have to go through just to find the one I needed.” — Verified User on G2

Pricing:

- Free plan: Not available

- Free trial: There is a 7-day free trial

- Paid plans: Subscription-based model; pricing starts around $20 per user/month for basic features; large organisations can request a custom quote

5. eMaint CMMS

eMaint is a long-standing and feature-rich CMMS solution (by Fluke Reliability) built to serve organizations that need strong preventive maintenance scheduling, asset tracking, and analytics in one platform. It offers flexibility and scalability, making it suitable for both small maintenance teams and large, multi-facility operations.

Best use case scenario: Best for organizations that want a mature, fully featured CMMS with advanced scheduling, reporting, and integration capabilities — and who don’t mind a steeper learning curve for the added depth.

Key features:

- Advanced scheduling tools: Create and manage PMs, recurring work orders, and technician schedules through intuitive calendar and list views.

- Work order management: Streamline creation, approval, and tracking of work orders, including automatic notifications and escalation rules.

- Parts and inventory management: Link spare parts to work orders and PMs to ensure materials are available when needed.

- Comprehensive reporting: Generate detailed KPI reports for schedule compliance, backlog, downtime, and cost analysis.

- Integration and scalability: Connects with ERP, IoT, and reliability tools (like vibration analysis and condition monitoring systems).

“This system is very versatile and customizable. It has helped us with better managing our pm schedules. Tech support is amazing.” — Wesley W. on Capterra

Limitations: The interface, while powerful, can feel dated compared to newer, lightweight CMMS tools. Implementation and configuration may take time for large or complex setups.

“PM Scheduling not flexible enough to account for variances in production schedule.” — Brian R. on Capterra

“Overall good experience with frustration in a few areas. Having to help develop the system. Example scheduler still not as user friendly as could be.” — Shimona S. on Capterra

Pricing

- Free plan: Not available

- Free trial: Not available

- Paid plans: Subscription-based model; pricing starts at $69 per user/month

6. MaintainX

MaintainX is a mobile-friendly CMMS designed to simplify how teams create, assign, and track maintenance work orders and schedules. It focuses on usability and collaboration, making it easy for technicians and managers to communicate, document work, and stay on top of maintenance work — all in real time.

Best use case scenario: Ideal for teams that want a simple, mobile-friendly maintenance management tool with strong scheduling and team communication features.

Key features:

- Calendar and recurring scheduling: Automate PMs and inspections on daily, weekly, or usage-based intervals to keep assets maintained consistently.

- Digital work orders: Create, assign, and complete work orders with photos, notes, and checklists directly from a mobile device.

- Real-time collaboration: Built-in chat and commenting keep technicians and managers connected on every task.

- Custom forms and procedures: Build templates and SOPs that attach to scheduled tasks for consistent execution.

- Reporting and analytics: Track KPIs like schedule compliance, response time, and downtime trends with automated reports.

“User-friendly interface, resource management features, scheduling options, visibility of all maintenance tasks, request tracking, and excellent return on investment.” — Verified Reviewer on Capterra

Potential limitations: MaintainX focuses on simplicity, so larger enterprises needing advanced custom workflows or deep ERP integrations may find it limited compared to heavier EAM systems.

“The lack of customizations and the lack of levels of access and cost.” — Verified Reviewer on Capterra

“There are some features that personally are not built up well enough yet. I think the due date and start date features for recurring work orders could be better, especially when you change a due date and apply to all future work orders in that tree. Also it’s very difficult to undo anything you do, you have to be very sure of the changes you make.” — Verified User on G2

Pricing:

- Free plan: Not available

- Free trial: Not available

- Paid plans: Subscription-based model; pricing starts around $20 per user/month

7. IBM Maximo

IBM Maximo is an established enterprise asset management (EAM) system, offering robust capabilities for work order management, preventive maintenance scheduling, asset tracking, and performance monitoring. It’s built for large organizations with complex maintenance operations that require scalability, advanced automation, and integration across departments.

Best use case scenario: Best suited for enterprises or multi-site organizations that need a deeply configurable maintenance scheduling system integrated with their EAM, ERP, or production systems.

Key features:

- Advanced scheduling and dispatching: Plan preventive and corrective maintenance tasks across large asset fleets using powerful rule-based scheduling engines.

- Work order management: Track every work order through its lifecycle — from creation to completion — with real-time visibility into labor, parts, and costs.

- Asset hierarchy and condition monitoring: Manage detailed asset structures and automate scheduling based on IoT sensor data or condition thresholds.

- Integrated labor and materials planning: Align technician schedules and parts availability directly with work orders to prevent delays.

- AI-driven insights: Leverage IBM’s AI and analytics to predict equipment failures and optimize preventive maintenance intervals.

- Extensive integrations: Connect Maximo with ERP, HR, and production systems for a unified operational view.

“What I like best about IBM Maximo Application Suite is how it brings everything together into a unified, modern platform. The integration of AI, mobile, and scheduling tools within the same environment really enhances operational efficiency.” — Helio R. on G2

Potential limitations: While Maximo is powerful, it’s also complex — requiring significant setup, configuration, training, and investment. Smaller teams may find it overkill for basic scheduling needs. Large teams might find its scheduling interface confusing.

“User interface is really really bad. Its user interface does not encourage you to use it. Even filling a simple from for raising a ticket is becoming a headache.” — Verified Reviewer on Capterra

“Maximo is not user friendly. Most of the screens has lots of fields which are all not used. It requires many training sessions for the users to start using Maxio.” — Priya M. on G2

Pricing

- Free plan: Not available

- Free trial: Not available

- Paid plans: Subscription-based model; pricing is quote-based and depends on deployment (cloud or on-premise), user count, and modules selected

Why Sockeye stands out as a top maintenance scheduling software

What really makes Sockeye stand out is its laser focus on one thing — scheduling. It was built from the ground up specifically for maintenance planners and schedulers who need a faster, easier way to build and manage schedules.

Sockeye’s biggest advantage is that it connects directly with your existing CMMS or EAM system. It pulls in ready-to-schedule work orders and returns a list of scheduled work orders and their current status.

Its interface mirrors how weekly scheduling actually happens in busy manufacturing plants.

- You check and update labor availability.

- Use the search to quickly find and select the work you want to schedule.

- Click on the “Schedule” button and let Sockeye’s automation do its thing.

- Review and polish the schedule.

All done in minutes, with just two screens to navigate. It’s simple, visual, fast — and the reason why Sockeye boasts an industry-leading 98% adoption rate.

If scheduling is the main problem with your existing maintenance software, there is no need to rip and replace it. Just implement Sockeye.

You can test Sockeye with a risk-free trial. This requires no IT involvement, just a copy of your schedule and an hour from your scheduler.

👉 See how Sockeye simplifies scheduling by getting a short product demo.

FAQs about maintenance scheduling software

Maintenance scheduling software helps maintenance teams assign and track all maintenance work — from preventive maintenance (PM) tasks to corrective and emergency repairs. It centralizes WOs, PMs, and technician availability in one place, so planners can easily build balanced, realistic schedules.

Yes, but they are few and far between. There are some basic Work Order solutions that let you receive tickets and schedule work. But those are geared toward property maintenance and field service companies and usually lack advanced functionality for scheduling preventive work. The best bet for industrial businesses is to look at scheduling bolt-ons like Sockeye.

Some maintenance scheduling software does support linking schedules to inventory levels, downtime windows, and production calendars. However, in many cases, manual updates, reviews, and coordination are still needed to keep everything on track.

The setup time for a maintenance scheduling module can vary widely — from hours to weeks — depending on your organization’s size, complexity of assets, existing systems and integrations, and the level of configuration needed.

Many modern solutions adopt strong security practices like encryption, role-based access control (RBAC) and multi-factor authentication (MFA) to ensure only authorized users can view or edit sensitive data. Additionally, reputable vendors often comply with recognized frameworks and certifications such as ISO 27001 or SOC 2.

he best way to demonstrate ROI is to connect the software’s impact to measurable business outcomes — reduced downtime, lower labor costs, and higher schedule compliance. Start by tracking your current baseline: how much time planners spend building schedules, how often PMs are missed, and how much reactive work disrupts production. After implementation, compare those metrics again.

Common ROI indicators include:

- Reduced unplanned downtime due to more consistent preventive maintenance.

- Higher technician productivity from balanced, automated scheduling.

- Lower overtime costs because workloads are better distributed.

- Improved asset reliability and extended equipment life.

- Less administrative time spent managing spreadsheets, entering data, or rescheduling work..

When you present results to management, translate these improvements into financial terms — hours saved, cost reductions, or avoided production losses. Concrete numbers tied to efficiency gains make a far stronger case than general statements about “improved scheduling.”