Every minute of unplanned downtime can cost manufacturers thousands of dollars in lost productivity. When production stalls unexpectedly, supply chains back up, delivery schedules slip, and teams scramble to recover — often under pressure and frustration.

Manufacturing downtime isn’t just a technical issue; it’s an organizational one. Equipment, people, and processes all play a role, which means preventing downtime requires strategy, not just quick fixes.

In this article, you’ll learn:

- Why unplanned downtime is so disruptive

- The most common causes and how to spot them early

- How to estimate the real cost of downtime for your plant

- Proven ways to minimize unexpected downtime on the production floor.

Let’s start with the basics.

What is manufacturing downtime?

Manufacturing downtime refers to any period when equipment or production lines are not operating as intended.

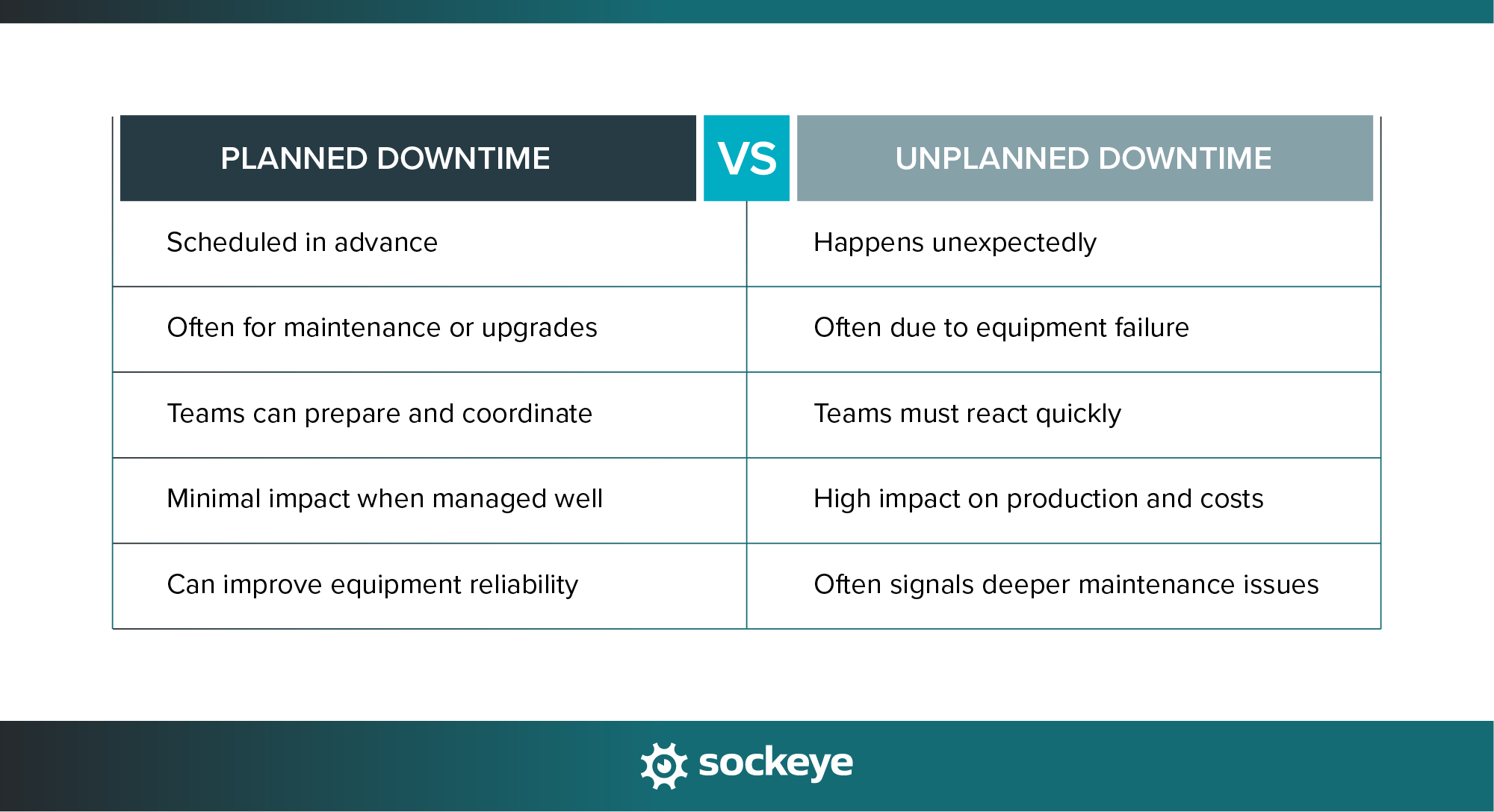

There are two main types of downtime:

- Planned downtime: Scheduled events like preventive maintenance, equipment upgrades, or changeovers. These pauses are expected and controlled.

- Unplanned downtime: Unexpected stoppages caused by equipment failures, material shortages, software glitches, or other disruptions.

While some downtime is inevitable, unplanned downtime is the most costly and disruptive. It throws off production schedules, delays order fulfillment, and reduces your Overall Equipment Effectiveness (OEE) — a key metric for plant performance.

Now, to actually reduce it, you first need to know why it happens.

Common causes of unplanned downtime in manufacturing

Pinpointing the root causes helps maintenance and production teams take targeted action — instead of just reacting when something breaks.

Here are the most common culprits behind unplanned downtime on the factory floor:

- Unscheduled maintenance & poor planning: Skipping preventive tasks or lacking a clear maintenance plan often leads to unplanned stoppages. It’s like going to the gym — you will see no results without a plan and consistency.

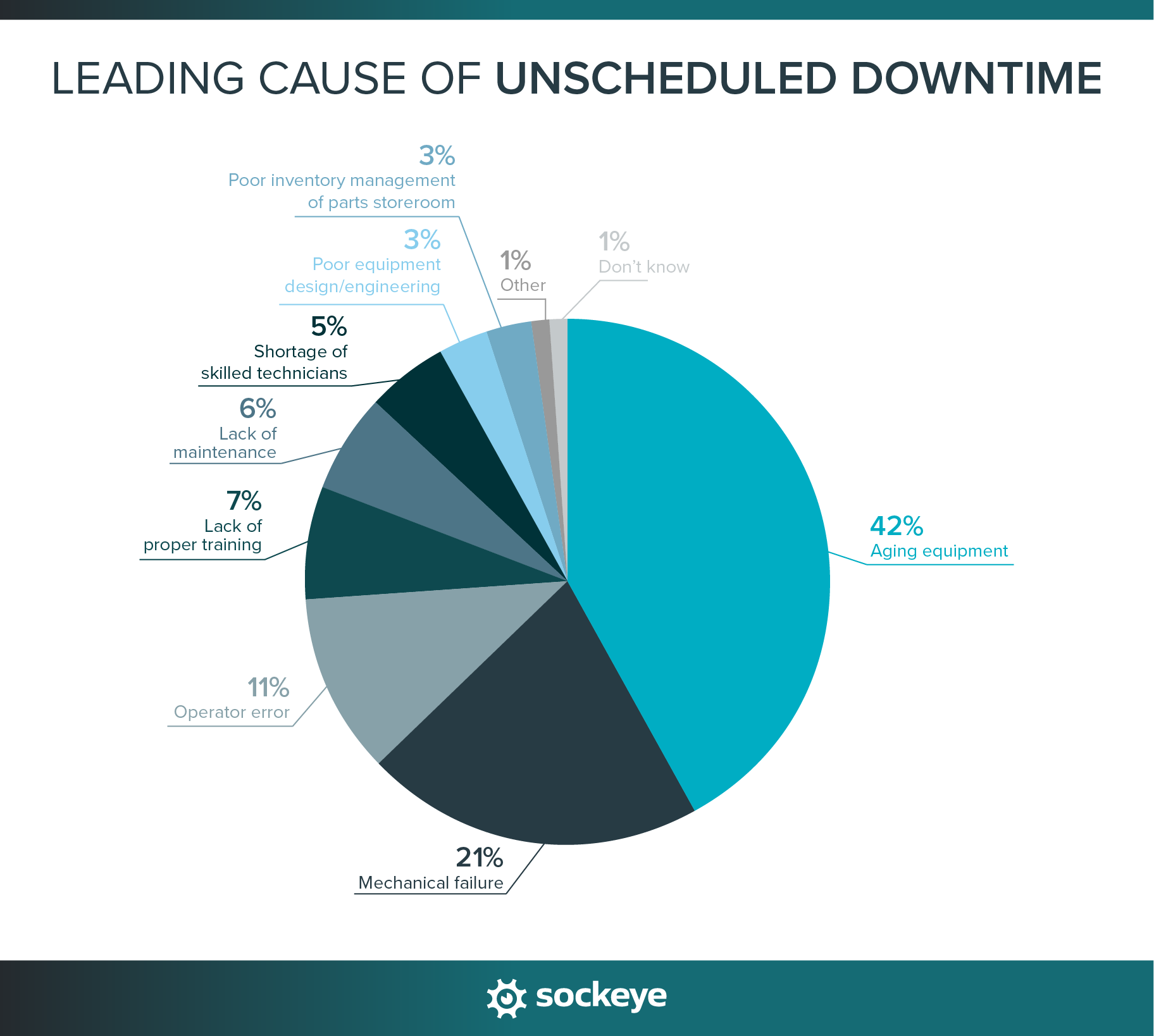

- Equipment failure: Mechanical breakdowns, worn parts, or aging machinery are among the biggest drivers of downtime. In fact, in the Plant Engineering 2021 Report, maintenance leaders reported that over 60% of unplanned failures were caused by aging assets and mechanical failures.

- Human error: Even in fairly automated environments, people still play a central role in operations. Improper equipment setup, skipped maintenance steps, or incorrect data entry can all trigger costly interruptions.

- Supply chain interruptions: When key materials, components, or packaging don’t arrive on time, production stops — no matter how well your equipment is running. Global supply chain volatility and just-in-time manufacturing practices have made this risk more visible than ever.

- Software or control system issues: Modern production lines rely on PLCs, HMIs, and integrated software. When these systems crash, lose connectivity, or experience bugs, downtime can ripple across multiple machines or even entire lines.

- Utility/weather outages: Unexpected power, water, or compressed air interruptions can instantly bring production to a standstill. Backup generators or energy monitoring systems can help reduce exposure to these risks.

The above chart shows the industry averages; you should still work on identifying root problems in your facility.

The average cost of manufacturing downtime

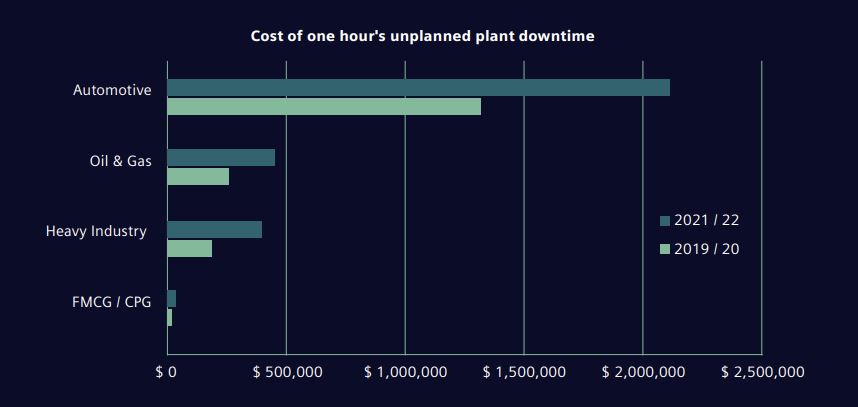

Unplanned downtime hits manufacturers hard — not just in lost production, but in a cascade of downstream costs:

- Direct costs include lost output, idle labor, scrap material, and (potential) emergency repair expenses. If your production line goes down, every minute of inactivity directly eats into profit.

- Indirect costs are less visible but just as damaging. Delayed shipments can strain customer relationships, while schedule changes create overtime costs and inefficiencies. Frequent breakdowns can also erode employee morale and confidence in management.

Siemens 2023 study suggests that average downtime costs go between 40k and 2 million per hour — based on sector and production volume.

To estimate your own downtime cost, multiply your plant’s average hourly production value by the duration of downtime, then add related expenses such as labor and material loss.

This gives a realistic picture of how much every hour of downtime truly costs your operation.

Effective ways to prevent unplanned downtime in manufacturing

Preventing unplanned downtime isn’t about eliminating every possible failure — it’s about reducing risk and responding faster when problems do occur. The best manufacturers track downtime trends, identify recurring issues, and focus their resources where they’ll have the biggest impact.

Start by monitoring key downtime KPIs such as:

- Mean Time Between Failures (MTBF) – how long equipment runs before breaking down.

- Mean Time to Repair (MTTR) – how quickly failures are fixed.

- Overall Equipment Effectiveness (OEE) – the combined measure of availability, performance, and quality.

These metrics give you the visibility to spot patterns and measure whether your improvement efforts are actually working.Now, let’s look at proven strategies to reduce downtime.

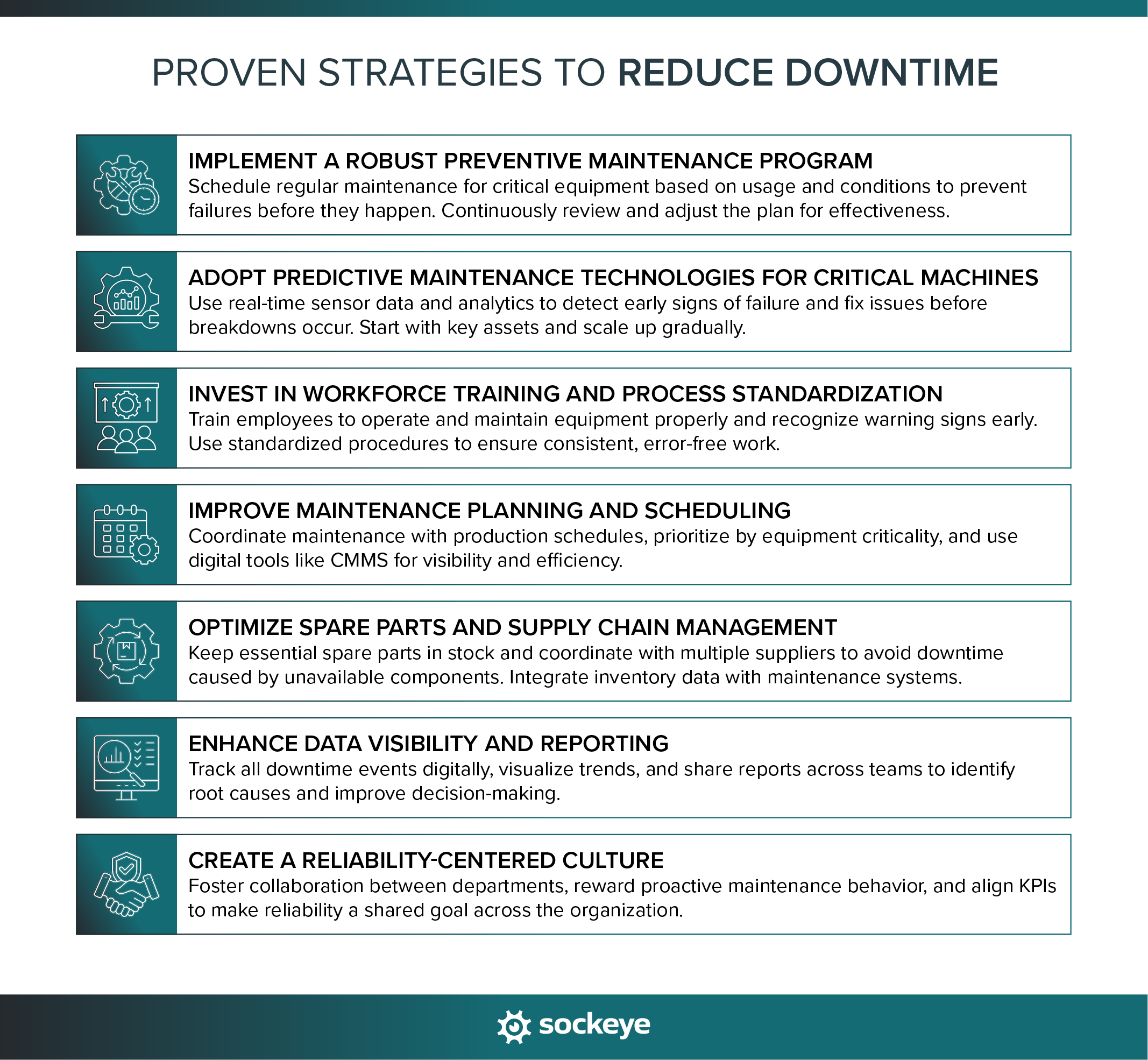

1. Implement a robust preventive maintenance program

A strong preventive maintenance (PM) program is your first line of defense against unplanned downtime. Instead of waiting for equipment to fail, you service it on a PM schedule — based on manufacturer recommendations, usage hours, and operating conditions.

Develop a structured PM plan that covers all critical assets, including detailed checklists, intervals, and responsibilities. But don’t just “set it and forget it” — review its effectiveness regularly. If failures still occur, adjust your schedule, procedures, or inspection criteria.

When done right, preventive maintenance improves equipment reliability and boosts OEE. It also lays the groundwork for reliability-centered maintenance (RCM) — where every maintenance task is tied directly to preventing a specific failure mode.

2. Adopt predictive maintenance technologies for critical machines

Preventive maintenance is effective, but predictive maintenance takes it a step further. Instead of servicing equipment on a fixed schedule, you use real-time data to predict when a failure is likely to occur — and act before it happens.

By installing sensors on critical machines, you can continuously monitor indicators like vibration, temperature, pressure, and power consumption. When readings start to drift from normal ranges, that’s an early sign of wear or malfunction.

Modern IoT platforms and CMMS integrations can analyze this data using machine learning to spot trends and forecast failures. For example, a rising vibration trend might suggest a bearing issue days before it becomes a breakdown.

It’s best to start small — pilot predictive maintenance on a few high-value assets, measure the results, develop workflows, and scale from there.

3. Invest in workforce training and process standardization

Many unplanned downtime events trace back to human error — setup and installation mistakes, skipped maintenance steps, overlooked warning signs, and various operator errors.

Aside from how to use the equipment properly, both technicians and operators should be able to recognize early symptoms of trouble. Empowering frontline employees to report or act early can have a huge ROI.

Standardized maintenance procedures (SOPs) also play a big role. When everyone follows clear, documented steps, work quality becomes more consistent and predictable. It reduces guesswork, improves safety, and ensures maintenance tasks are completed correctly — even under time pressure.

In short, skilled, well-trained people following standardized processes are one of the most effective safeguards against downtime.

4. Improve maintenance planning and scheduling

With all of the worker shortages going around, to keep up with the schedule, work needs to be planned or coordinated effectively.

Start by establishing a formal maintenance schedule that prioritizes tasks based on equipment criticality and production impact. Then, coordinate with production teams to align maintenance windows with planned downtime or low-demand periods.Use digital tools such as a Computerized Maintenance Management System (CMMS) or EAM software to track work orders, assign technicians, and monitor backlog. You’ll have an easier time seeing what’s overdue, what’s in progress, and where bottlenecks are forming.

Tip: If managing maintenance schedules inside your CMMS or EAM feels overly complex or time-consuming, consider using Sockeye maintenance scheduler. Sockeye acts as an external scheduling bolt-on that integrates with your existing maintenance software — allowing you to outsource the scheduling function while keeping all maintenance data fully synced and up to date.

Finally, hold regular maintenance-planning meetings — weekly or monthly — between production and maintenance teams. Reviewing upcoming jobs, priorities, and recent issues together ensures proactive decision-making instead of reactive firefighting.

5. Optimize spare parts and supply chain management

Proper maintenance planning ensures that the right parts or materials are available when needed. Don’t let unplanned downtime events drag on simply because a spare part is missing.

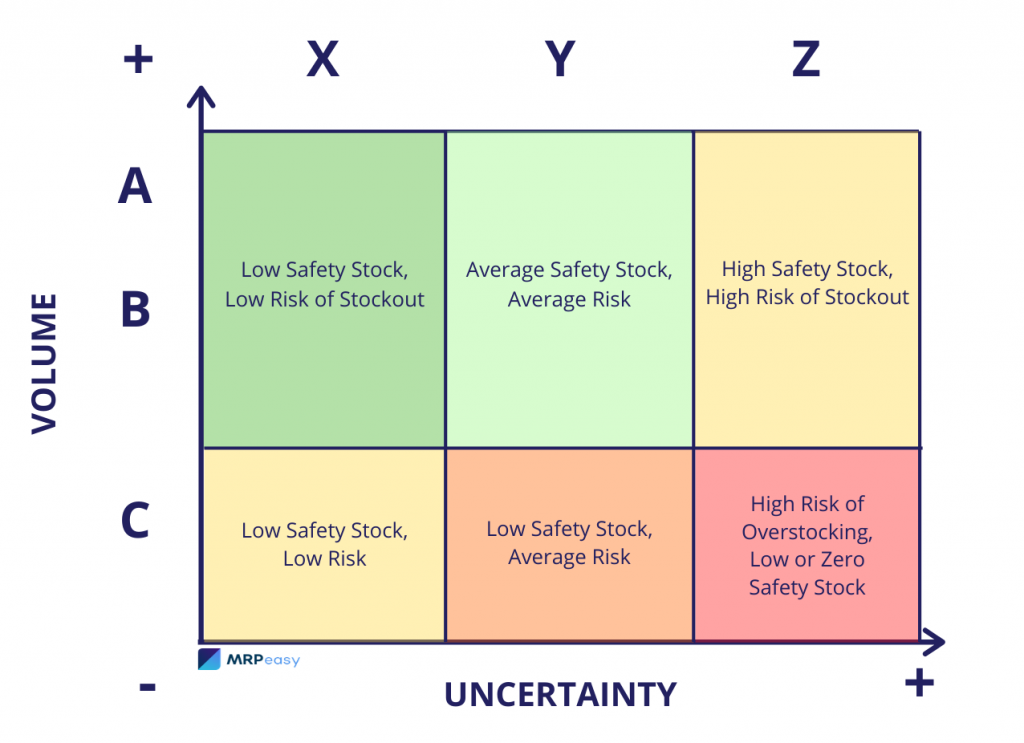

Identify critical spare parts and ensure they’re always in stock through ABC or risk-based classification. Start by identifying which parts are truly critical — the ones that could stop production if unavailable — and classify them using ABC and XYZ methods. Continue managing your parts inventory stock levels based on that classification.

Establish vendor agreements or consignment programs for fast delivery of essential components, and maintain good relationships with multiple suppliers to avoid single points of failure.

If your systems allow, integrate inventory data with your production and maintenance platforms so everyone has real-time visibility into what’s available and what’s on order. This ensures planners and schedulers can organize and assign work confidently.

6. Enhance data visibility and reporting

Too often, we see organization struggling with downtime data that is incomplete, inaccurate, or buried in spreadsheets. This makes it borderline impossible to spot recurring problems.

Ideally, you would implement a digital downtime tracking system that automatically logs every event, including its duration, affected equipment, and cause. While there are specialized software, many CMMS and EAM solutions should be able to help you track downtime.

When you have that downtime data, use dashboards and reports to visualize trends:

- Which machines fail most often?

- What shifts experience the most downtime?

- Are specific failure types becoming more frequent?

Use these insights to prioritize your efforts where they’ll deliver the biggest return.

Do not forget to share downtime data across teams — production, maintenance, and management. Regularly reviewing performance metrics together builds accountability. Plus, when downtime visibility improves, so does decision-making.

7. Create a reliability-centered culture

The most reliable plants aren’t just equipped with great tools — they’re driven by a culture of reliability. Preventing downtime is everyone’s job, not just maintenance’s.

Encourage collaboration between maintenance, production, and quality teams so they share information freely and solve problems together.

Make sure to recognize and reward proactive behavior — like early fault reporting, process improvement ideas, or consistent adherence to maintenance standards. Small acts of accountability can create big cultural shifts.

Lastly, try to align key performance indicators across departments. When teams share metrics, they share ownership. It’s how reliability becomes part of the plant’s DNA.

Building resilience against downtime

Building resilience starts small. Begin by auditing your current downtime events, identifying repeat offenders, and benchmarking your costs. Then, pick one or two focus areas — like tightening your preventive maintenance schedule or improving spare parts readiness — and build momentum from there.

Every subsequent improvement will strengthen your operation’s ability to stay productive and profitable when unexpected issues arise.

The goal isn’t to eliminate downtime completely — it’s to make your plant more predictable, more responsive, and more resilient.