BEVERAGE PLANT MAINTENANCE SCHEDULING SOFTWARE

A Simpler Way to Schedule Maintenance for Your Bottling & Beverage Plant

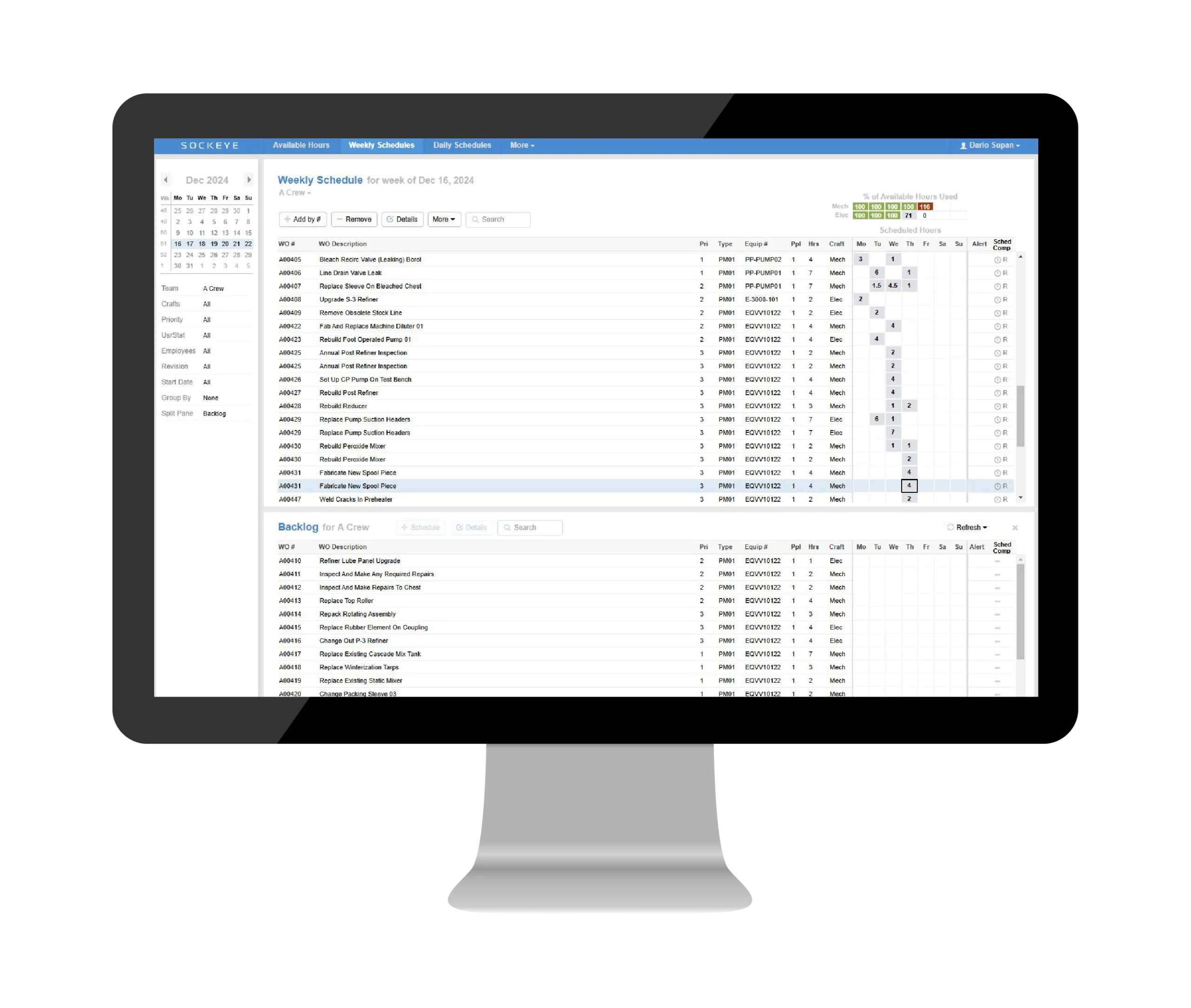

Schedule WOs and PMs in a couple of clicks based on real-time personnel availability. Track work progress, identify reasons for delays, and optimize your weekly and daily schedules around tight cleaning and production windows.

Trusted by bottling and beverage plants worldwide

Sockeye takes just 1 hour to learn — and 98% of plants who try it keep using it for the long haul.

Here’s how Sockeye works

KEY FEATURES

Automatic scheduling

Schedule visualization

Work order status tracking

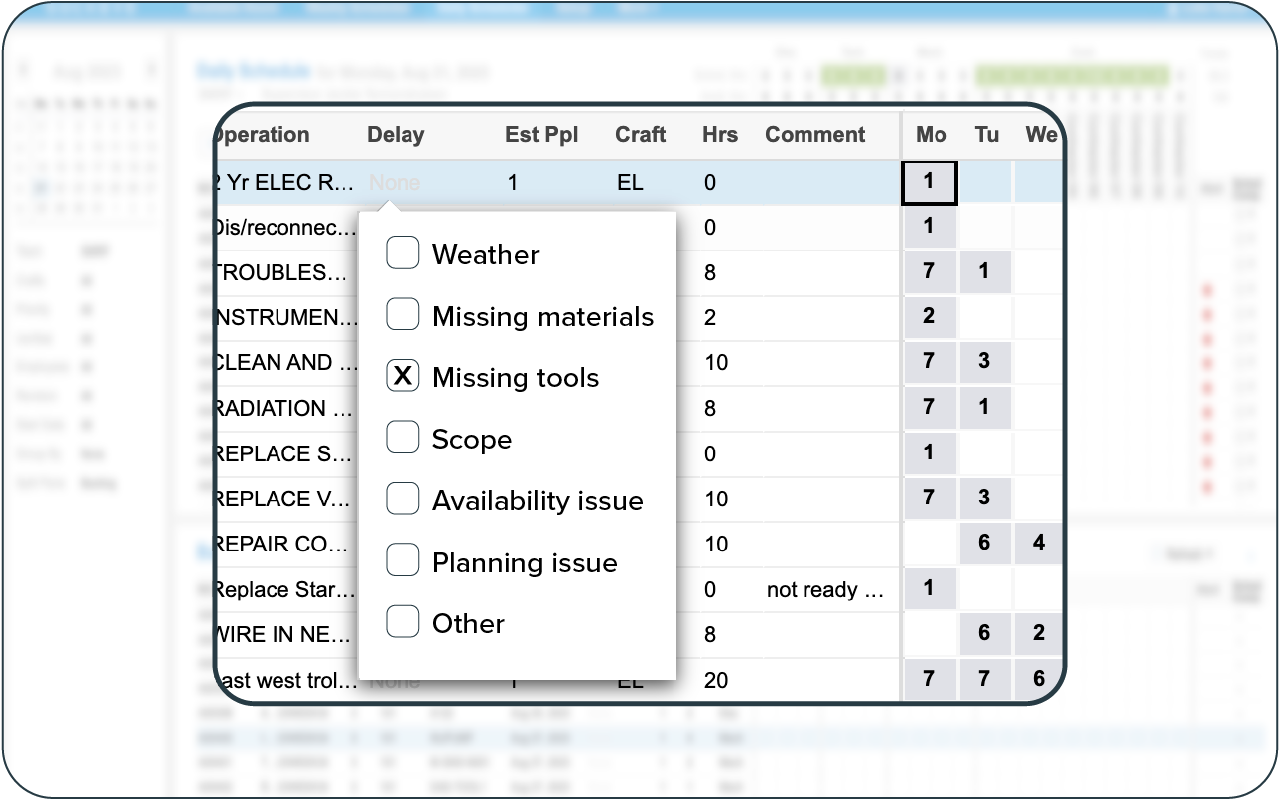

Delay reasons tracking

SMRP and custom KPI reports

Full CMMS/HR system integration

Perfect for

Wineries that have a CMMS or EAM

Sockeye works best as a bolt-on. If you struggle to schedule work through Excel and CMMS, you can use Sockeye’s intuitive interface instead.

Teams battling labor shortages

Manual or clunky scheduling slows you down. Our automation help you schedule work faster, leaving more time for job planning and preparation.

Simple & consistent PM scheduling

Sockeye is built solely for maintenance scheduling — easy to implement, simple to use, and focused on helping beverage plants stay reliable and compliant.

Test Sockeye for 30 days.

No IT involvement required.

Confirm user adoption and get a proof of concept before spending a single cent.

TAKE THE FREE TRIALMAINTENANCE SCHEDULING AUTOMATION

Simplify weekly & daily PM scheduling

Keep up with critical preventive tasks like lubrication, inspections, and cleaning without throwing off production runs. Sockeye’s automation helps you build realistic weekly and daily schedules in minutes, not hours.

When ready, publish and share live schedules to keep your frontline teams aligned and accountable. You can easily reschedule work by dragging and dropping tasks to the next available slot.

LABOR AVAILABILITY DASHBOARD

Always knows who is available

Labor shortages and overlapping production schedules make balancing workloads tough. Sockeye’s real-time crew and contractor availability data helps you level work across teams and shifts, scheduling everyone near 100% of capacity.

“Sockeye identifies where deficiencies are in your man hours. For instance, if Crew A is 40 hours over schedule, but Crew B is only 35% scheduled, you can move your resources to level it out to avoid overtime pay. That saves you money.”

Todd Hicks, Planning and Shutdown Superintendent at the AV Group

EQUIPMENT RELIABILITY

Prevent downtime with smarter scheduling

In bottling and beverage plants, even a short breakdown on a filler or capper can cause major production losses. Sockeye gives your team the tools to prioritize preventive work, track delay reasons to spot recurring issues, and give planners more time to prepare jobs correctly.

The result: less reactive firefighting, increased equipment uptime, and smoother production.

AUTOMATED KPI REPORTING

Track and report key scheduling metrics

Automatically generate SMRP-aligned and custom KPI reports to track key metrics like schedule compliance, labor utilization, preventive vs. reactive work, and backlog trends — then freely send that data into your BI tools for deeper analysis.

Sockeye’s split-pane view makes it easy to see how specific work orders impact reliability and other KPIs, showing how effective your current maintenance schedule really is.

REGULATORY COMPLIANCE

Stay audit-ready with a documented schedule

Beverage plants face strict sanitation and quality standards. Sockeye helps you stay compliant with a live, documented maintenance schedule that keeps your team aligned and your records audit-ready.

Always know what work has been completed, what’s in progress, and what’s coming next — with a clear digital trail to show inspectors.

Schedule more work.

Get more work done.

Let us help you create a highly productive maintenance team.

Book a DemoBottling & beverage plant maintenance best practices

Keeping high-speed bottling and beverage lines running safely and efficiently takes discipline, proactive planning, and the right tools. The following best practices can help keep your maintenance team on track with minimal impact on production.

1) Plan maintenance around production and sanitation needs

Beverage plants often run around the clock to meet demand, and sanitation cycles are non-negotiable for food safety. Planned downtime is limited, so every minute counts.

Coordinate across production, QA, and maintenance to align preventive tasks with clean-in-place (CIP) schedules or planned shutdowns. Develop detailed plans ahead of time, assigning tasks and allocating resources to avoid conflicts.

For example, using a scheduling tool like Sockeye makes it easier to view available windows, assign work to technicians who are available and possess the necessary skills, and keep all departments aligned with a shared schedule.

The more precise the plan, the more value you’ll get from each maintenance window without jeopardizing product quality.

2) Use shift-structured scheduling to fit tight windows

Most bottling and beverage operations run multiple shifts or continuous schedules, which means maintenance work has to fit into narrow time slots.

Build your maintenance schedule around actual crew patterns — day/night or 12-hour rotations — to make sure preventive work gets done consistently. Use a scheduling tool that visualizes labor availability by crew and shift. This will help you balance workloads across teams and keep critical PMs on track without disrupting bottling operations.

To make the most of your maintenance windows, standardize PM checklists and procedures for common tasks like lubrication, alignment, sanitation, and part replacements. This speeds up work without compromising safety or quality.

3) Prioritize inspections of high-speed filling and packaging equipment

Fillers, cappers, conveyors, and labelers operate at high speeds and are prone to wear, misalignment, and contamination. Even a minor failure on these machines can ripple through your entire production schedule.

Regular inspections, lubrication, and cleaning should be part of your core PM program. Track recurring failure points to address root causes before they escalate, and make sure alignment and sanitation checks are built into your weekly routines to protect uptime and product quality.

You’ll also want to actively track why PMs get delayed, so you can make necessary changes that enable your team to stick to the schedule.

4) Coordinate vendor work well ahead of major outages

OEM technicians and specialized contractors are often essential for inspections, upgrades, or complex repairs — but their calendars fill up fast. To avoid delays during critical outages, start engaging vendors early.

Share your planned downtime dates months in advance, confirm their resource needs, and integrate their tasks into your overall maintenance schedule.

Define clear timelines and work scopes so everyone knows where they fit. For example, you can send contractors a simple one-page outline listing the start/end times for their work, the equipment they’ll be working on, safety requirements, and any dependencies with other crews.

By securing vendor commitments early and aligning their schedules with yours, you reduce the risk of missed work, workaround solutions, and prolonged downtime.

5) Maintain audit-ready maintenance records

Regulatory compliance is a fact of life in beverage production, with HACCP, FDA, ISO, and sanitation audits all demanding detailed documentation.

You’ll want to:

- Digitize your records: Keep all maintenance and sanitation PMs in one system with timestamps for what was done, when, and by whom.

- Standardize work documentation: Use consistent checklists and forms so all crews capture the same information every time.

- Tag compliance-critical tasks: Clearly mark tasks related to HACCP, sanitation, or safety audits to ensure they get priority and proper sign-off.

- Store supporting evidence: Attach photos, calibration reports, and vendor service logs to your digital records for a complete audit trail.

- Automate reporting: Use scheduling/CMMS tools to quickly generate reports by date range or equipment for inspectors.

- Review records regularly: Spot-check logs and close out missing information before audits are on the horizon.

By following these steps — and managing it all in a digital system — you’ll always have verifiable, audit-ready documentation when inspectors arrive.

EAM/CMMS scheduling bolt-on

Simplified WO management for high-speed bottling plants

Tired of bouncing between your CMMS, spreadsheets, and shift notes — while preventive work is still falling behind? Sockeye is built to handle the pace, compliance, and crew coordination demands of bottling and beverage plants.

BOOK A DEMOStep 1

Get a Customized Demo

We start with a call from one of our product specialists to understand your specific needs. We then run a customized demo with your entire team so you can see how Sockeye makes scheduling easy.

Step 2

Start Your Risk-Free Trial

Test drive Sockeye using a file-based integration (Excel). This requires no investment or IT resources and just a few hours from the scheduler. Verify that Sockeye is right for you before you go all in.

Step 3

Get the Most out of Your Team

No more disjointed scheduling, missing data, & flying blind. Consistently build daily/weekly schedules, check the latest status, and maximize preventive maintenance by maximizing productivity.

Frequently Asked Questions

Sockeye uses two primary types of integration:

1. API-Based Integration

Sockeye uses API-based integration to adapt to every enterprise’s unique needs, providing customized read/write configurations with your maintenance and/or HR systems. This means that any last-minute changes made in your CMMS are reflected in Sockeye — and vice versa.

2. File-Based Integration

Sockeye uses an Excel template to port data between the CMMS and Sockeye — simply export your CMMS data into Sockeye’s Excel template and click ‘refresh’ to update your data. The implementation requires minimal effort and no IT resources or custom coding.

Learn more about integration types

A full production rollout with API integration takes 4 to 6 weeks, while a file-based integration can be done in under 2 weeks.

Sockeye’s experts handle most of the integration work; your IT team just needs to provide access (API endpoints or database views) and some oversight. Because Sockeye is cloud-based, there is no server to install or software to maintain on-premises — it’s all handled by our cloud infrastructure.

Yes, Sockeye offers a one-month trial using our file-based integration. You’ll get access to all of Sockeye’s features and support throughout the trial. To get started, share an Excel file of your schedule and join a 1-hour training session.

Sockeye supports read/write CMMS integration. The exact data exchanged typically includes work order details, scheduling fields, and resource info.

Configurations can be customized as read-only or selective write-back to accommodate your IT/security policies.

Work orders are updated according to your requirements. Typically, work orders are automatically updated when the scheduled work order end date has been reached. Work order updates made in your CMMS and Sockeye are automatically synchronized in both systems.

Sockeye allows you to input your technician and contractor shift patterns to track labor availability. You can easily edit labor availability for vacations, training, etc, with a couple of clicks.

Yes, Sockeye integration is customized according to your unique scheduling and IT requirements. Read/write integration, read only, write only specific fields, etc. — Sockeye is designed to meet your enterprise’s unique integration requirements.

We take data security very seriously. Sockeye is hosted on Microsoft Azure, which has industry-standard certifications (like ISO and SOC 2). Data is always encrypted, and backups are stored in a separate geographic region.

On the access side, we support role-based user permissions, SSO (Single Sign-on), and 2FA (two-factor authentication).

From Fortune 100 enterprises to single-site enterprises, Sockeye is ready, vetted, and prepared for your IT security review.

Learn more about Sockeye’s security

Schedule more work.

Get more work done.

Let us help you create a highly productive maintenance team.

BOOK A DEMO